Water-tolerant type magnesium phosphate cement-based material and preparation method thereof

A magnesium phosphate cement, water-resistant technology, applied in the field of cementitious materials, can solve the problems of poor water resistance, easy to be eroded by water, enlarged pores of the matrix, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

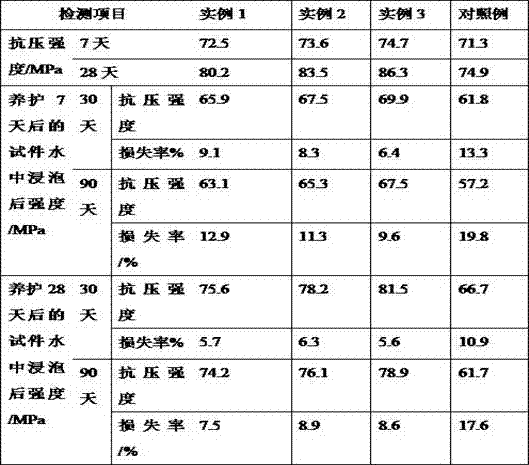

example 1

[0025] First, collect the waste water of the phosphoric acid plant and the excess sludge of the domestic sewage treatment plant, and mix the waste water of the phosphoric acid plant and the excess sludge of the domestic sewage treatment plant in an equal mass ratio to obtain a mixture. , stirring reaction for 1h; after the stirring reaction is over, filter and separate to obtain the filtrate, dropwise add sodium sulfide solution with a mass fraction of 20% to the filtrate until no more precipitation is produced in the filtrate, filter to remove the precipitation, and obtain secondary Filtrate; add the secondary filtrate to calcium hydroxide powder in a mass ratio of 5:1, stir and react for 10 minutes to obtain a mixed suspension, then add the mixed suspension to anhydrous ethanol in a mass ratio of 1:2, and continue to stir and react for 1h , filter to obtain a filter cake, which is a compound phosphoric acid compound; the compound phosphoric acid compound, plant polyphenols an...

example 2

[0027]First, collect the wastewater from the phosphoric acid plant and the remaining sludge from the domestic sewage treatment plant, mix the wastewater from the phosphoric acid plant and the remaining sludge from the domestic sewage treatment plant in an equal mass ratio to obtain a mixture, put the mixture into a reaction kettle, and heat up to 75°C , stirred and reacted for 2 hours; after the stirred reaction was completed, filtered and separated to obtain the filtrate, a sodium sulfide solution with a mass fraction of 20% was added dropwise to the filtrate until no more precipitates were produced in the filtrate, and the precipitate was removed by filtration to obtain the second Filtrate: add the secondary filtrate to the calcium hydroxide powder according to the mass ratio of 5:1, stir and react for 13 minutes to obtain a mixed suspension, then add the mixed suspension into absolute ethanol according to the mass ratio of 1:2, and continue to stir and react for 2 hours , fi...

example 3

[0029] First, collect the wastewater from the phosphoric acid plant and the remaining sludge from the domestic sewage treatment plant, mix the wastewater from the phosphoric acid plant and the remaining sludge from the domestic sewage treatment plant in an equal mass ratio to obtain a mixture, put the mixture into a reaction kettle, and heat up to 80°C , stirred and reacted for 2 hours; after the stirred reaction was completed, filtered and separated to obtain the filtrate, a sodium sulfide solution with a mass fraction of 20% was added dropwise to the filtrate until no more precipitates were produced in the filtrate, and the precipitate was removed by filtration to obtain the second Filtrate: add the secondary filtrate to the calcium hydroxide powder according to the mass ratio of 5:1, stir and react for 15 minutes to obtain a mixed suspension, then add the mixed suspension into absolute ethanol according to the mass ratio of 1:2, and continue to stir and react for 2 hours , f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com