Hot field for single crystal furnace and single crystal furnace

A single crystal furnace and thermal field technology, which is applied in the fields of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve the problems of difficulty in taking into account at the same time, so as to reduce the cost of crystal pulling, improve the pulling speed, and optimize the temperature gradient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

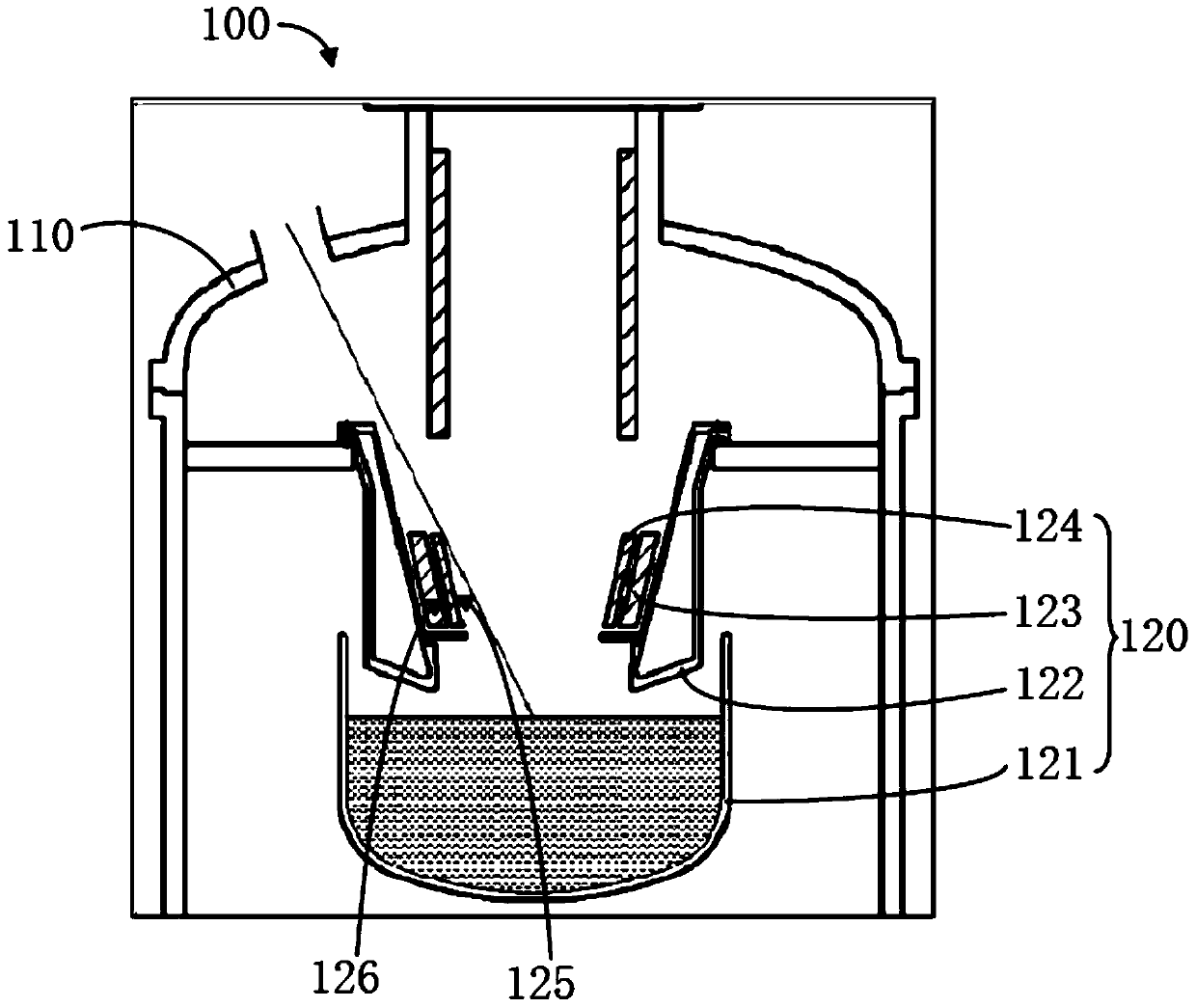

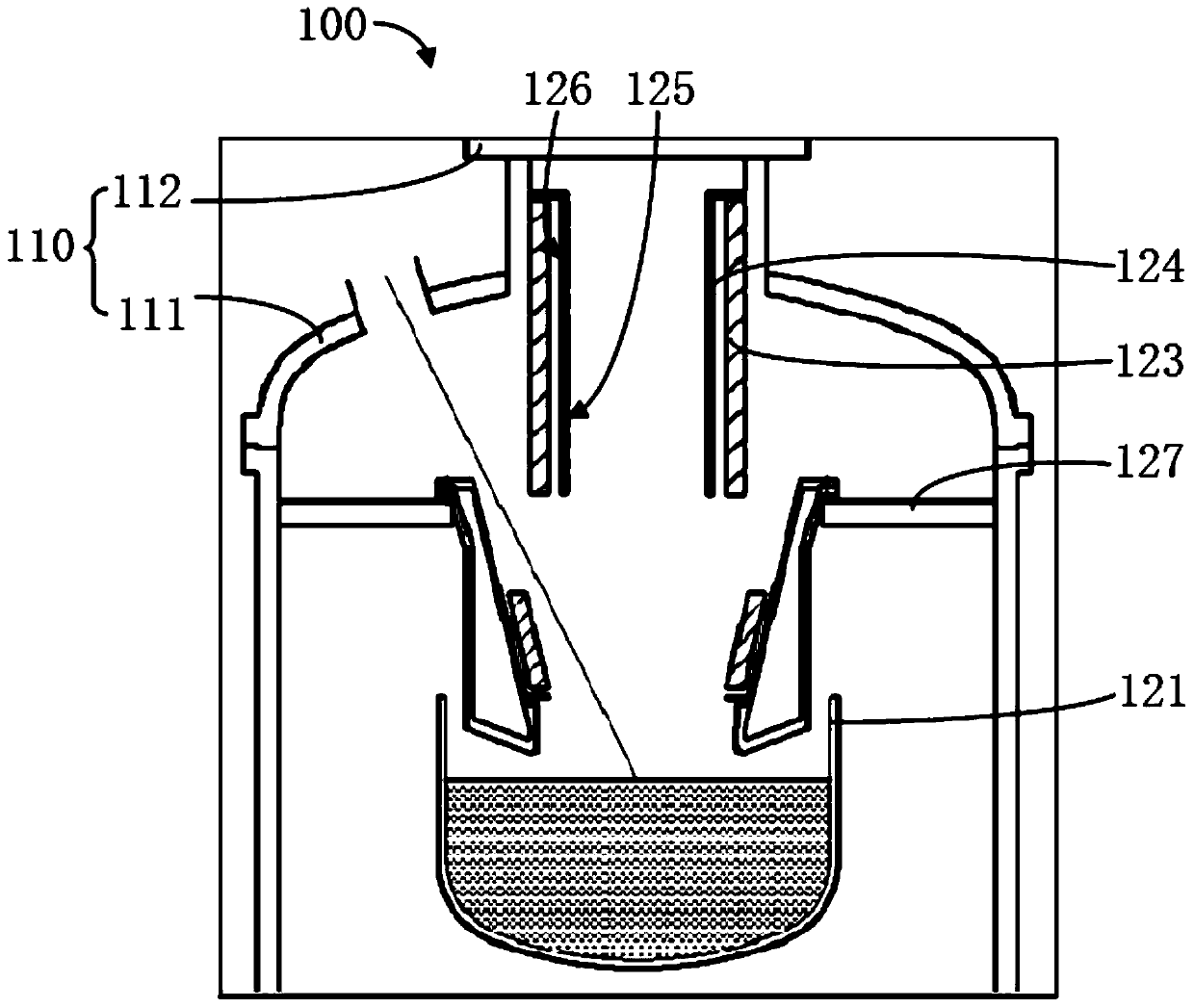

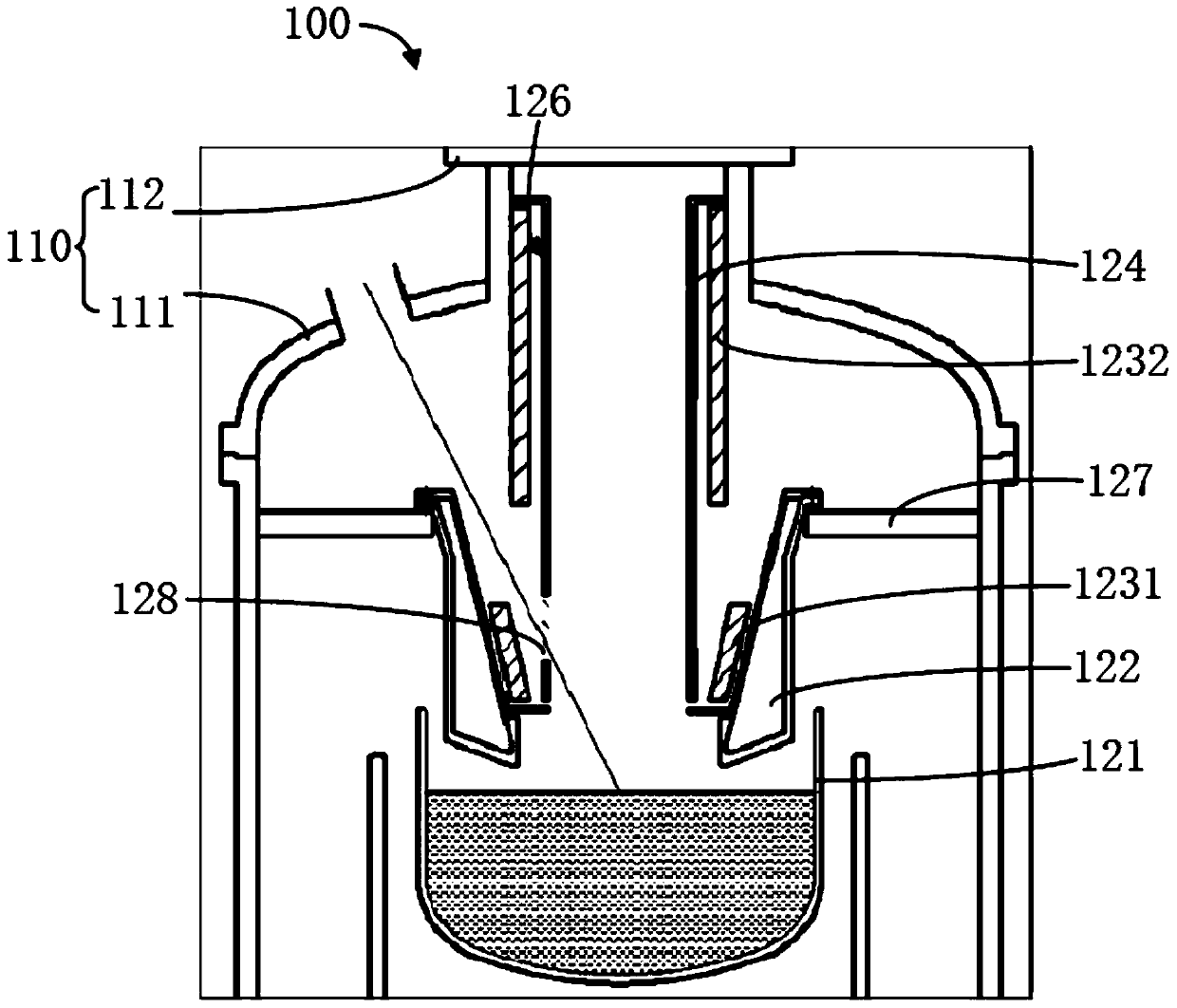

[0023] The structural sectional view of the single crystal furnace 100 provided by the first embodiment of the present invention is as follows figure 1 As shown, a furnace body 110 and a thermal field 120 for a single crystal furnace located in the furnace body 110 are included.

[0024] The thermal field 120 for a single crystal furnace includes a crucible 121 , a heat shield 122 , a cooling element 123 and a sheath 124 . The heat shield 122 , the cooling element 123 and the sheath 124 are all located above the crucible 121 . From the side wall of the crucible 121 toward the central axis, there are heat shield 122 , cooling element 123 and sheath 124 in sequence. That is, the cooling element 123 is located between the heat shield 122 and the sheath 124 , and the sheath 124 is disposed on a side of the cooling element 123 close to the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com