Absorption heat pump

An absorption heat pump and absorption liquid technology, applied in the field of absorption heat pump, can solve the problems of restricted setting conditions, height increase, and high height of absorption heat pump, and achieve the effect of high assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in each figure, the same or similar reference numerals are assigned to mutually identical or corresponding components, and overlapping descriptions will be omitted.

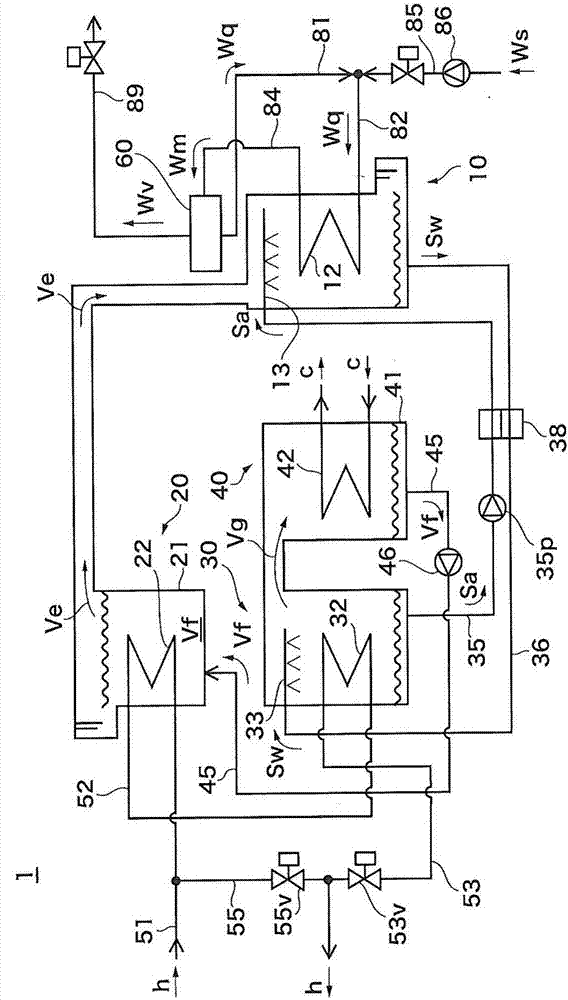

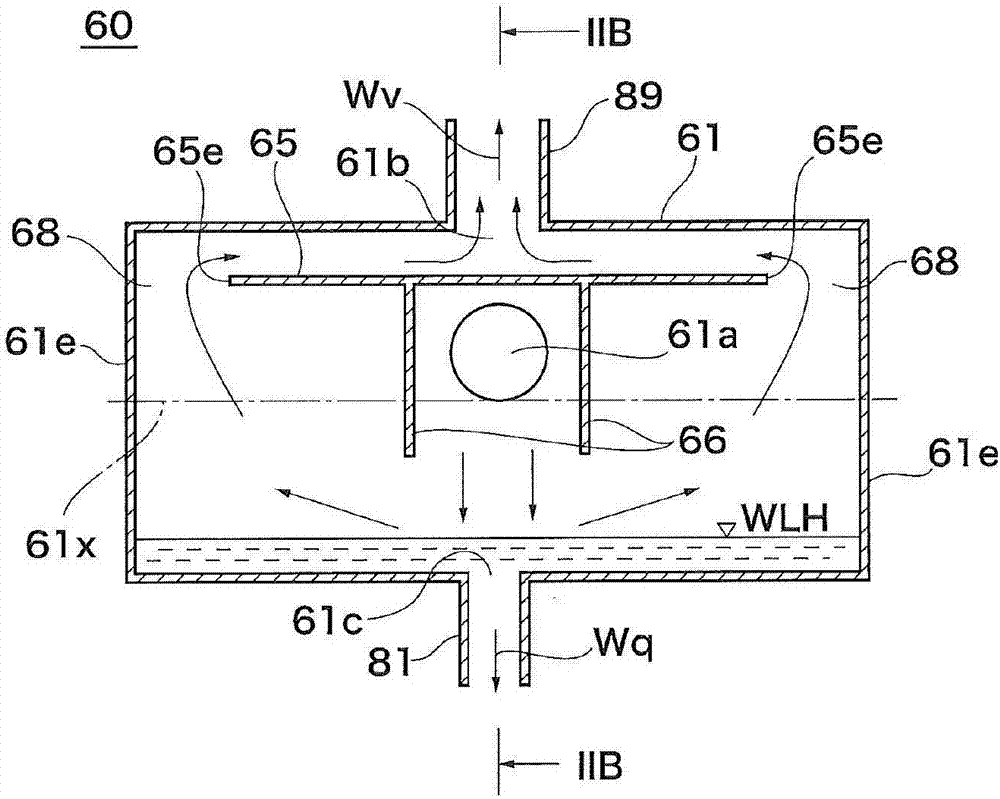

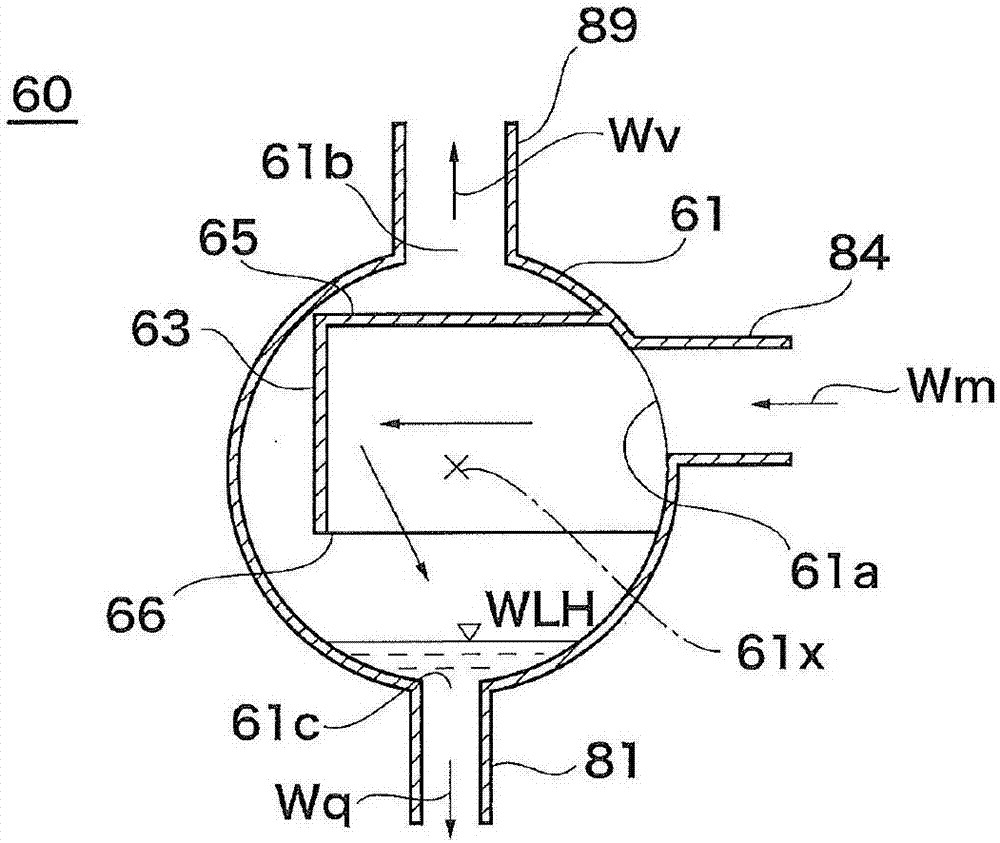

[0024] First, refer to figure 1 The absorption heat pump 1 according to the embodiment of the present invention will be described. figure 1 is a schematic system diagram of the absorption heat pump 1 . The absorption heat pump 1 includes an absorber 10 , an evaporator 20 , a regenerator 30 , and a condenser constituting main equipment for an absorption heat pump cycle of an absorption liquid S (Sa, Sw) and a refrigerant V (Ve, Vg, Vf). 40, and a gas-liquid separator 60 is also provided.

[0025] In this specification, the absorption liquid is referred to as "dilute solution Sw", "concentrated solution Sa", etc. according to its properties and positions on the heat pump cycle in order to easil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com