Cotton drying machine

A drying machine and cotton technology, applied in the textile field, can solve the problems of low drying efficiency and achieve the effect of improving drying efficiency and reducing water vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

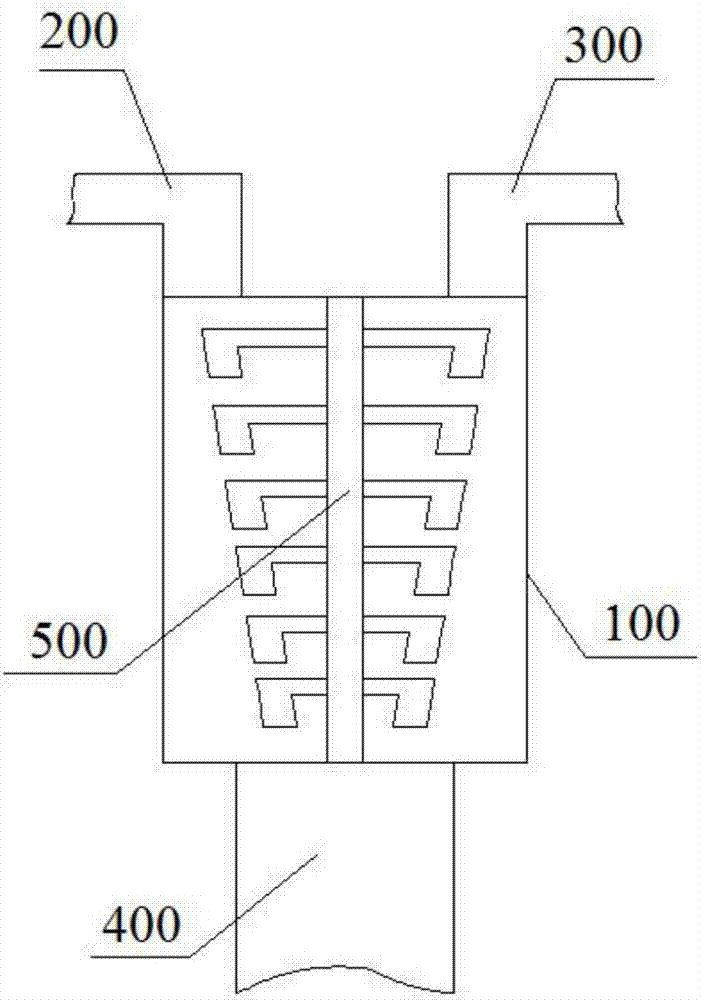

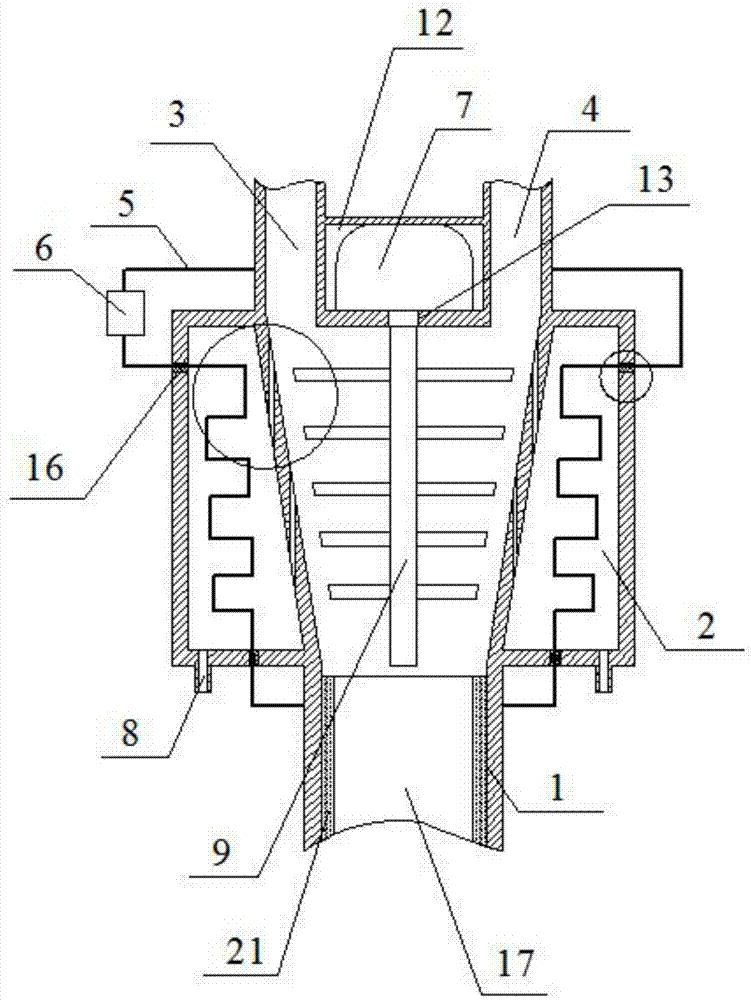

[0026] Such as Figure 2 to Figure 6 As shown, the embodiment of the present application provides a cotton dryer, including: a drying box 1, a condensation box 2, a cotton inlet passage 3, a hot air passage 4, a condensation pipe 5, a circulation pump 6, a motor 7, a stirring rod 9 and an outlet Cotton Channel 17. The drying box 1 is used to dry the cotton, and the condensation box 2 is used to condense the water vapor generated during the cotton drying process and discharge it in time. The cotton inlet channel 3 is used to load the cotton to be dried, and the hot air channel 4 is used to connect with the hot air source, so that air with a higher temperature is introduced into the drying box 1 to dry the cotton in the drying box 1 .

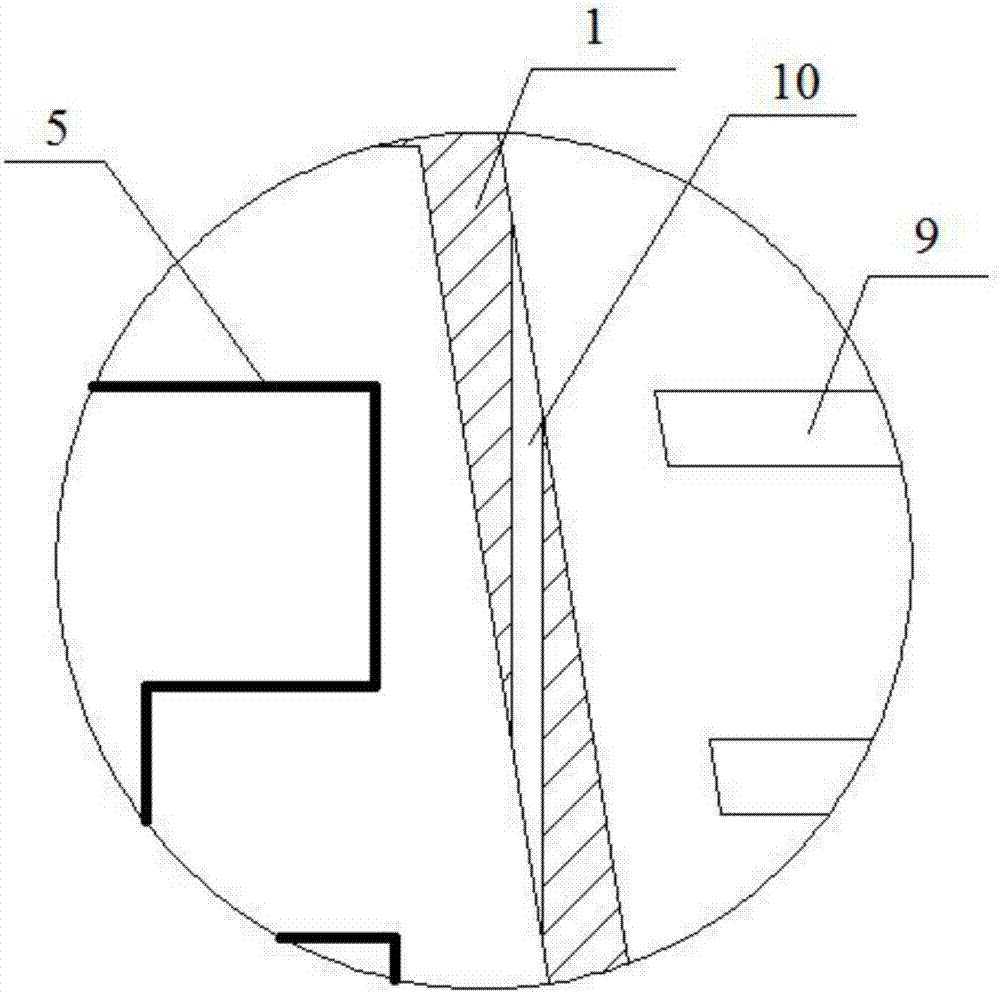

[0027] Wherein, the width of described drying box 1 decreases gradually from top to bottom, and the side wall of described drying box 1 is provided with a plurality of exhaust holes 10, and in the present embodiment, the diameter of described ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com