Dual heat resistant steel furnace roller

A technology of heat-resistant steel and furnace rolls, which is applied in the field of furnace rolls, can solve the problems of easy bending of processed products and furnace rolls, thick roll body structure, poor bearing capacity, etc., and achieve enhanced load-bearing strength, long service life, and heat transfer. slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

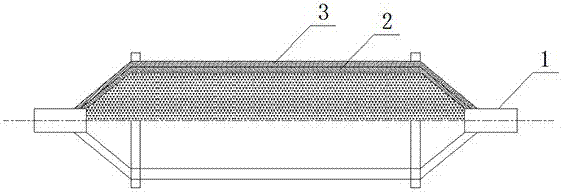

[0016] Such as figure 1 As shown, a double heat-resistant steel furnace roll includes a furnace roll body 1, and the roll body of the furnace roll body 1 includes an inner layer roll body 2 and an outer layer roll body 3, and the outer side of the inner layer roll body 2 is arranged There is an outer roller body 3, the inside of the inner layer roller body 2 is filled with thermal insulation materials, and the surface of the outer layer roller body 3 is provided with a nano-coating; the roller body of the furnace roller body 1 is made by centrifugal casting; wherein , the inner roll body 2 is made of high-temperature heat-resistant alloy steel Cr2520Ni20 material, the outer roll body 3 is made of high-temperature heat-resistant alloy steel Cr28Ni48W5 material, and the thermal insulation material is made of ceramic fiber material.

[0017] In summary, the roll body of the double heat-resistant steel furnace roll of the present invention adopts a double structure, the inner laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com