Drop-hammer impact tension-compression integrated load test conversion device

A technology of load test and drop weight impact, applied in the field of drop weight impact tension-compression integrated load test conversion device, can solve the problems of complex structure and force transmission mechanism, and achieve convenient design and manufacture, simple processing and manufacturing, and simple device structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

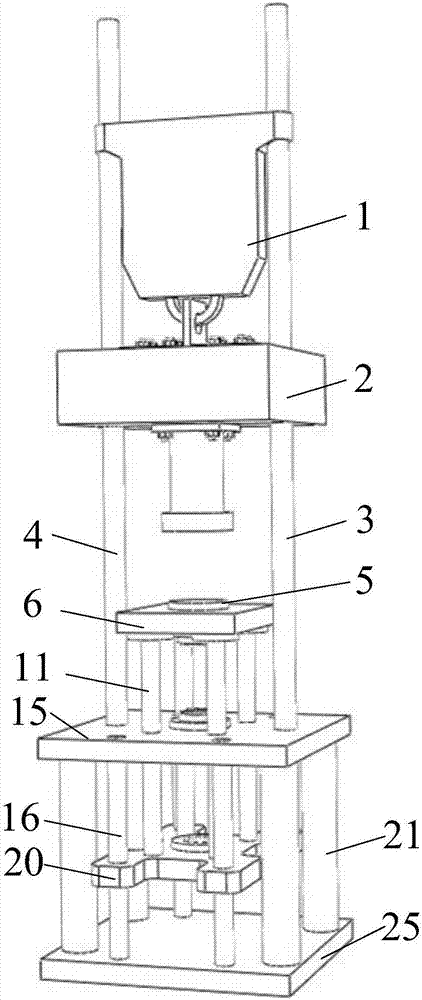

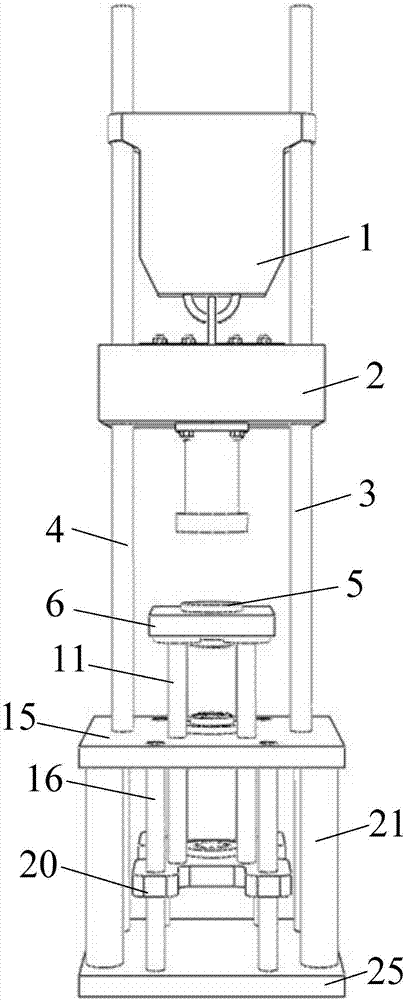

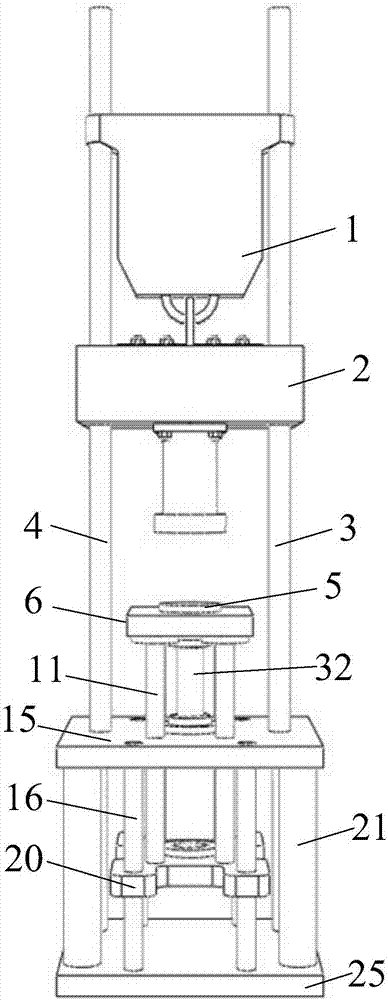

[0031] A drop-weight impact tension-compression integrated load test conversion device is composed of a drop-weight test loader, a tension-compression integrated loading mechanism and a base, see figure 1 and figure 2 . drop weight test loader figure 1 As shown, it consists of a positioning fixture 1, a drop hammer body 2 and hammer body guide rails 3,4. The positioning fixture 1 is fixed on the guide rails 3 and 4, and the drop hammer body 2 is hooked on the positioning fixture 1. By releasing the hook, the drop hammer body applies an impact load vertically along the guide rails. The compression loading part of the tension-compression integrated loading mechanism is as follows: image 3 , Figure 5 and Figure 6 As shown, it is made up of an impact platform 6, four connecting guide rods 11, 12, 13, 14 and a fixed platform 15, and a buffer pad 5 is placed at the central impact point on the impact platform 6. The tensile loading part of the tension-compression integrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com