Incoming material checking method of magnetic core

An inspection method and technology for magnetic cores, which are applied in the analysis of materials, material analysis by optical means, instruments, etc., can solve the problem that the inspection method of incoming magnetic cores has not yet been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail in conjunction with the following examples, so that those skilled in the art can implement it with reference to the description.

[0014] The incoming inspection method of magnetic core of the present invention comprises the following steps:

[0015] Step 1: Visual inspection: whether the magnetic core is deformed, demagnetized, smooth and not rough, crystallized, etc., select a few magnetic cores to break, and observe whether the internal structure is evenly distributed.

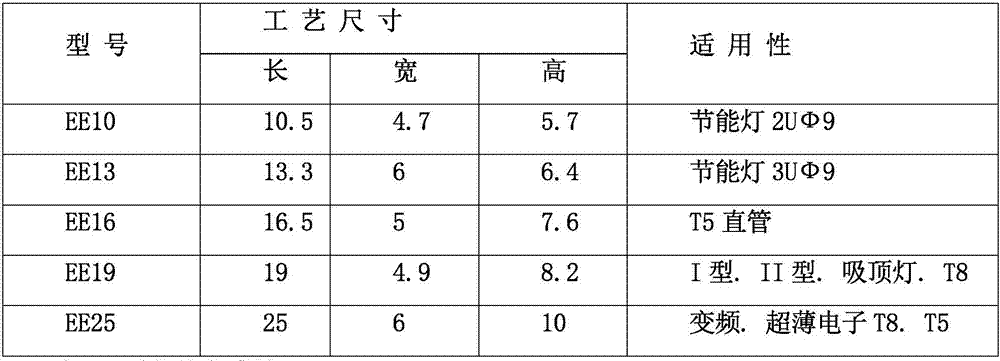

[0016] Step 2: Process size: Measure the length, width, height and air gap of the magnetic core according to the specifications.

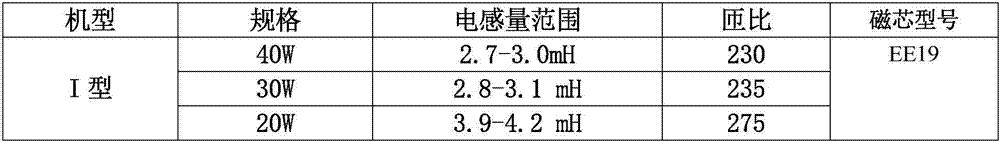

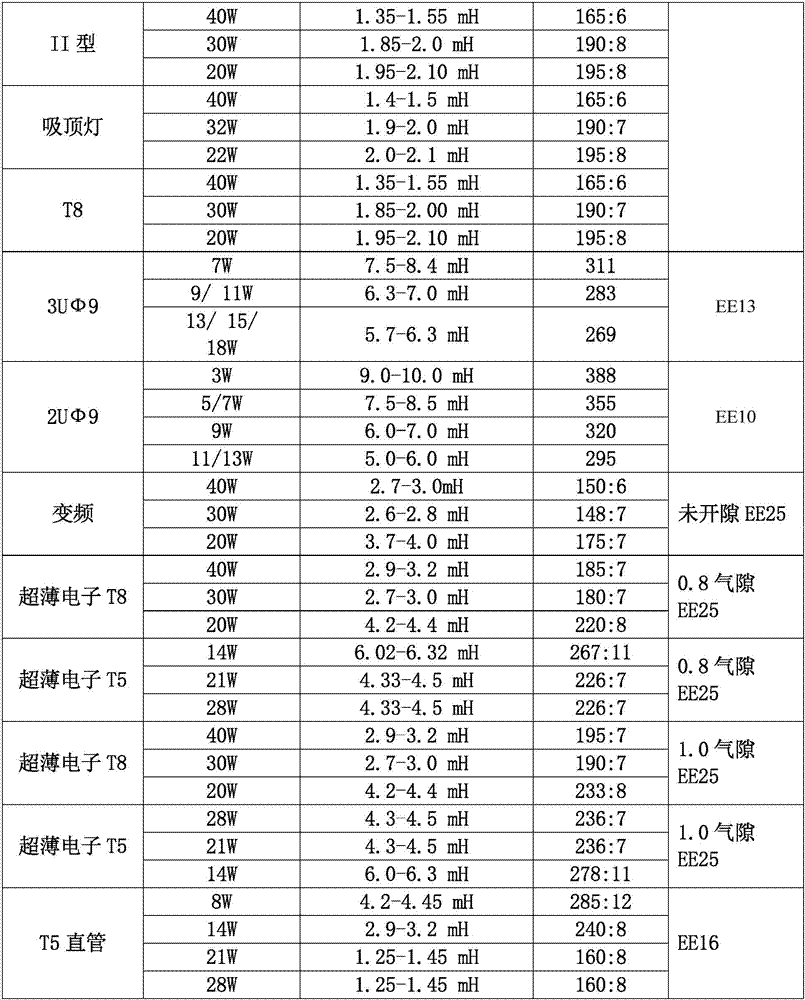

[0017] Step 3: Instrument measurement: Measure the inductance of the magnetic core with an inductance meter.

[0018] Step 4: Temperature rise: measure the inductance at room temperature with the transformer made of the magnetic core to be tested (one for each specification), record the number and put it in the ov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap