Lithium-ion battery separator

A lithium-ion battery and separator technology, which is applied in battery pack parts, circuits, separators/films/diaphragms/spacers, etc., can solve problems such as complicated processes, and achieve excellent liquid absorption and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

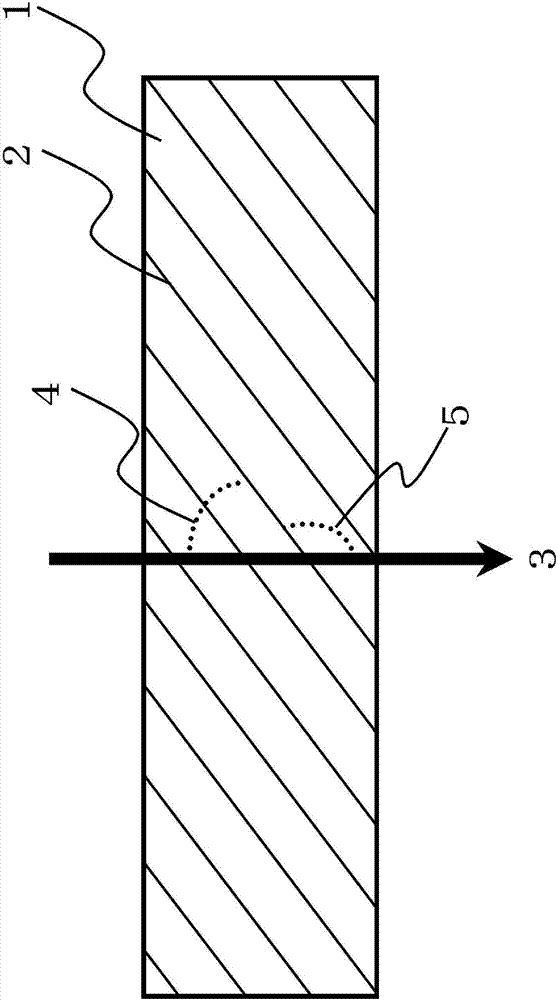

[0104] On one side of the non-woven fabric substrate A, the coating solution A was coated with a gravure coater (KRG) of the reverse contact (Kiss Reverse) method and dried so that the absolute dry coating amount became 16g / m 2 Thus, a separator with a thickness of 36 μm was produced. The angle 4 between the injection direction and the tank is +40°.

Embodiment 2

[0106] On one side of the non-woven fabric substrate A, the coating solution A was coated with a reverse contact gravure coater and dried so that the absolute dry coating amount became 16g / m 2 Thus, a separator with a thickness of 36 μm was produced. The angle 4 between the injection direction and the tank is +70°.

Embodiment 3

[0108] On one side of the non-woven fabric substrate A, the coating solution A was coated with a reverse contact gravure coater and dried so that the absolute dry coating amount became 16g / m 2 Thus, a separator with a thickness of 36 μm was produced. The angle 4 between the injection direction and the tank is +15°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com