Lithium-sulfur battery electrolyte with core-shell structure, and preparation method thereof

A lithium-sulfur battery and electrolyte technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of maintenance, adverse battery safety performance, poor thermal stability and mechanical strength, etc., and achieve cycle stability. and safety improvement, good guiding significance, excellent liquid absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

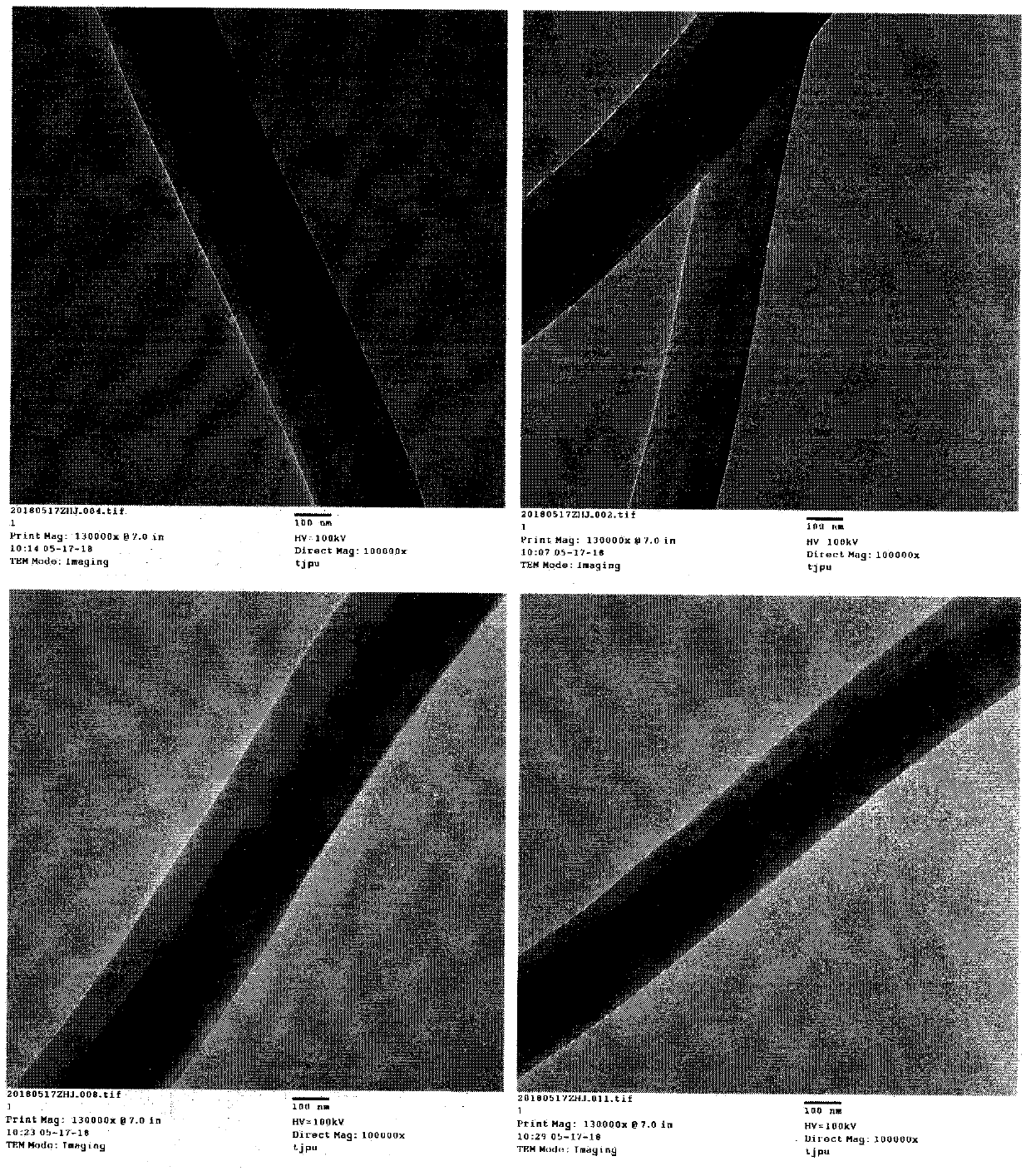

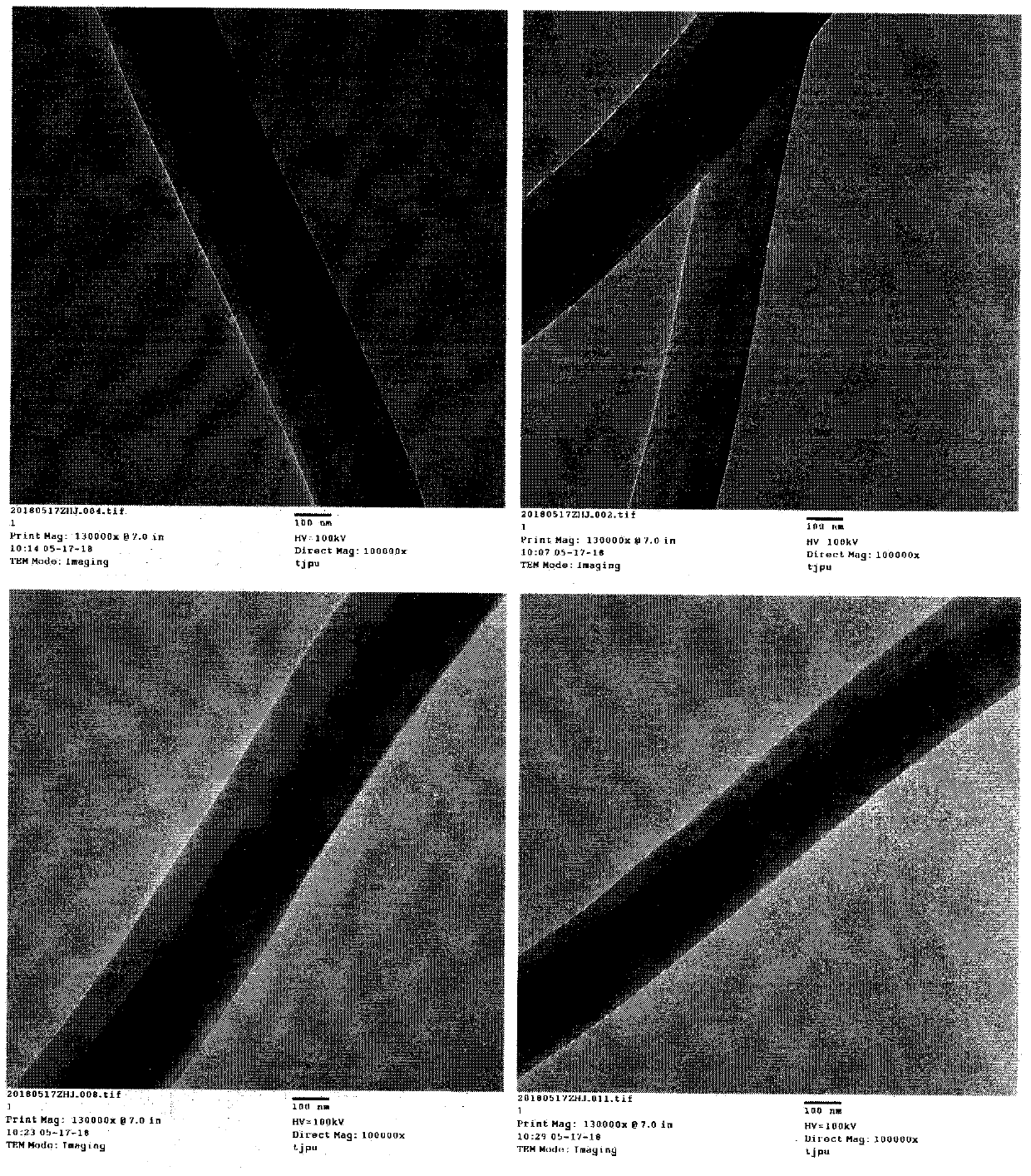

[0027] (1) the aramid fiber emulsion that concentration is 20wt% joins in dimethylacetamide (the ratio of the two volumes is 1: 5) in the organic solvent, utilizes magnetic stirrer to stir 6 hours under normal temperature condition then to form the homogeneous mixing solution, and then drop a certain amount of Oliphobol in the aramid / dimethylacetamide mixture TM 7713) emulsion (ratio by volume is 4:20:1), then the resulting mixed solution was stirred at a high speed for 12 hours at room temperature to form a uniform and stable shell silk solution; the dried 4,4'-diaminodiphenyl Add ether (ODA) to a certain amount of dimethylformamide, then use a magnetic stirrer to stir at room temperature for 1 hour to form a uniformly mixed solution, and then add a certain amount of 1,2,4,5-pyromellitic dianhydride (PMDA), and then the formed mixed solution was stirred at a high speed for 12 hours at room temperature to form a uniform and stable core polyamic acid spinning solution with a m...

Embodiment 2

[0032] (1) the aramid fiber emulsion that concentration is 20wt% joins in dimethylacetamide (the ratio of the two volumes is 1: 5) organic solvent, utilizes magnetic stirrer to stir 6 hours under normal temperature condition then to form the uniform mixing solution, and then drop a certain amount of Oliphobol in the aramid / dimethylacetamide mixture TM 7713) emulsion (ratio by volume is 4:20:1), then the resulting mixed solution was stirred at a high speed for 12 hours at room temperature to form a uniform and stable shell silk solution; the dried 4,4'-diaminodiphenyl Add ether (ODA) to a certain amount of dimethylformamide, then use a magnetic stirrer to stir at room temperature for 1 hour to form a uniformly mixed solution, and then add a certain amount of 1,2,4,5-pyromellitic dianhydride (PMDA), and then the formed mixed solution was stirred at a high speed for 12 hours at room temperature to form a uniform and stable core polyamic acid spinning solution with a mass fractio...

Embodiment 3

[0037] (1) the aramid fiber emulsion that concentration is 20wt% joins in dimethylacetamide (the ratio of the two volumes is 1: 5) in the organic solvent, utilizes magnetic stirrer to stir 6 hours under normal temperature condition then to form the homogeneous mixing solution, and then drop a certain amount of Oliphobol in the aramid / dimethylacetamide mixture TM 7713) emulsion (ratio by volume is 4:20:1), then the resulting mixed solution was stirred at a high speed for 12 hours at room temperature to form a uniform and stable shell silk solution; the dried 4,4'-diaminodiphenyl Add ether (ODA) to a certain amount of dimethylformamide, then use a magnetic stirrer to stir at room temperature for 1 hour to form a uniformly mixed solution, and then add a certain amount of 1,2,4,5-pyromellitic dianhydride (PMDA), and then the formed mixed solution was stirred at a high speed for 12 hours at room temperature to form a uniform and stable core polyamic acid spinning solution with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com