A kind of quasi-solid electrolyte and its preparation method and application

An electrolyte, quasi-solid-state technology, applied in the direction of solid electrolyte, non-aqueous electrolyte, electrolyte immobilization/gelation, etc., can solve the problems of unsatisfactory conductivity of all-solid electrolyte, flammable electrolyte, lithium dendrites, etc. Achieve the effects of improving conductivity and interface stability, improving safety performance, and enhancing rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

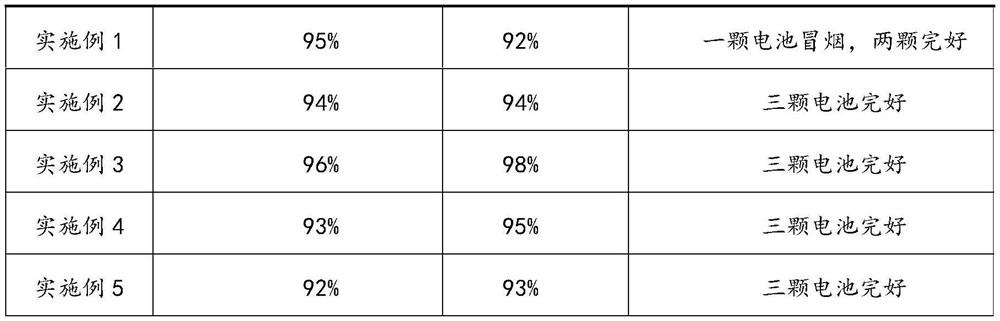

Embodiment 1

[0041] This example discloses a quasi-solid electrolyte and its preparation method and application. In this example, ZMS-5 is used for screening mesoporous molecules;

[0042] Raw material ratio of quasi-solid electrolyte: 50wt% methyl methacrylate, 30wt% LAGP, 20wt% ZMS-5, the amount of acetonitrile is 4 times the mass of reactants;

[0043] Dissolve methyl methacrylate in acetonitrile, stir at a speed of 5000rpm and fully dissolve, then add high-concentration phosphate Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 and ZMS-5, at 60°C, stirring at a speed of 5000rpm, stirring slowly for 48 hours, to obtain a liquid composite polymer solid electrolyte, continue the reaction until the acetonitrile is completely volatilized, and dry to obtain a solid composite polymer solid electrolyte.

[0044] In this embodiment, the quasi-solid-state electrolyte is prepared by in-situ polymerization, using methyl methacrylate as the skeleton and phosphate-based materials with high salt concentration to p...

Embodiment 2

[0060] The main difference between this embodiment and embodiment 1 is:

[0061] Raw material ratio of quasi-solid electrolyte: 60wt% methyl methacrylate, 10wt% LAGP, 30wt% HMS, and the amount of acetonitrile is 4 times the mass of reactants;

[0062] Dissolve methyl methacrylate in acetonitrile and stir at a speed of 10000rpm. After fully dissolving, add high-concentration phosphate Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 and HMS, at 50°C, stirring at a speed of 10,000rpm, stirring slowly for 40 hours, to obtain a liquid composite polymer solid electrolyte, and continue the reaction until the acetonitrile is completely volatilized, and dried to obtain a solid composite polymer solid electrolyte.

Embodiment 3

[0064] The main difference between this embodiment and the embodiment is:

[0065] Raw material ratio of quasi-solid electrolyte: methyl methacrylate 70wt%, LAGP 20wt%, MCM-41 10wt%, the amount of acetonitrile is 4 times the amount of reactants;

[0066] Dissolve methyl methacrylate in acetonitrile and stir at a speed of 15000rpm. After fully dissolving, add high-concentration phosphate Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 and MCM-41, at 40°C, stirred at a speed of 15000rpm, stirred slowly for 32 hours to obtain a liquid composite polymer solid electrolyte, and continued to react until the acetonitrile was completely volatilized and dried to obtain a solid composite polymer solid electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com