Lithium ion battery electrolyte, preparation method thereof and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of poor cycle stability and low safety, and achieve the effect of preventing decomposition and improving cycle stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

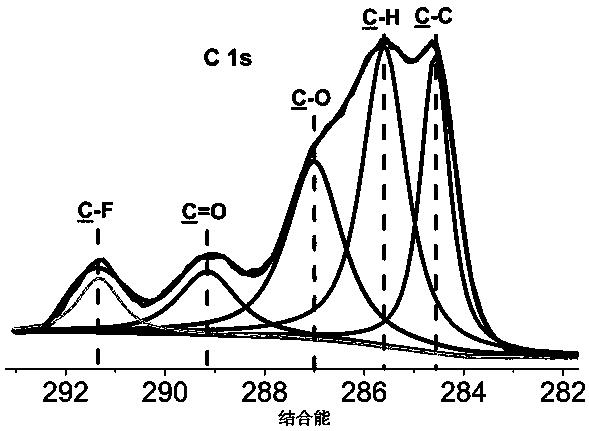

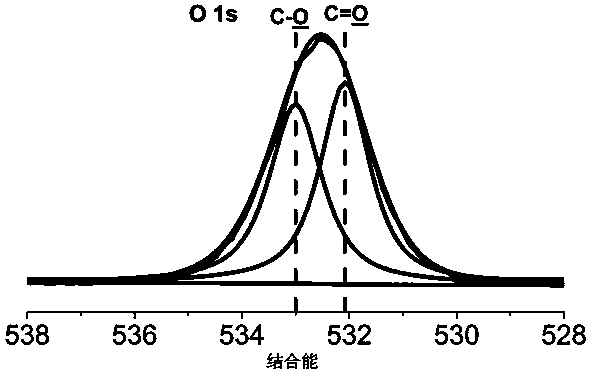

Image

Examples

Embodiment 1

[0045] Preparation of lithium-ion battery electrolyte: Under normal temperature and pressure, in an argon-filled glove box (oxygen and water content less than 0.1ppm), the ionic liquid 1-butyl-1-methylpiperidine bis(trifluoromethanesulfonate The acyl)imide salt and sulfolane are uniformly mixed according to the mass ratio of 6:4 to obtain a mixed solvent. Based on the mass, lithium difluorooxalate borate with a concentration of 0.5 mol / kg in the mixed solvent was added to the mixed solvent, and mixed uniformly to obtain 10 g of lithium-ion battery electrolyte.

[0046] Preparation of lithium-rich pole piece: Add lithium-rich layered oxide, conductive agent acetylene black, and binder polytetrafluoroethylene at a mass ratio of 8:1:1 to N-methylpyrrolidone (NMP), mix The positive electrode slurry is uniformly obtained, and then the slurry is uniformly coated on the aluminum foil, dried at a temperature of 70° C., and sliced to obtain a lithium-rich electrode sheet.

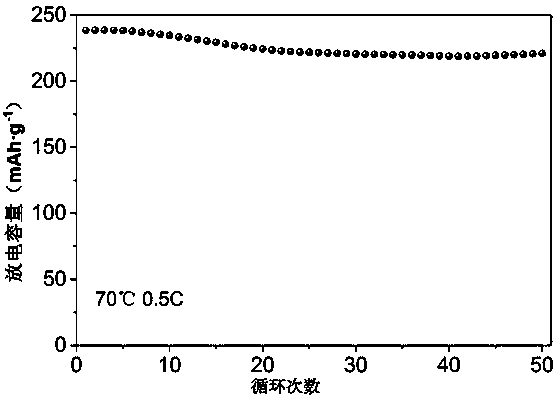

[0047] P...

Embodiment 2

[0052] Under normal temperature and pressure, in a glove box filled with argon (oxygen and water content less than 0.1ppm), the ionic liquid 1-hydroxyethyl-3-methylimidazolium tetrafluoroborate and ethylene sulfite were mixed according to the mass Mix evenly with a ratio of 8:2. Based on the mass, add lithium difluorooxalate borate with a concentration of 0.4M / kg in the mixed solvent into the mixed solvent, and mix evenly to obtain 10 g of lithium-ion battery electrolyte.

[0053] The lithium-rich positive electrode was prepared according to the preparation method of the lithium-rich positive electrode in Example 1.

[0054] A battery was prepared according to the method for preparing the battery in Example 1.

[0055] After the prepared battery was left to stand for 24 hours, Shenzhen Fuyida constant temperature and humidity box was used to control the ambient temperature at 85°C, and Wuhan Landian CT2001A battery test system was used to test the cycle performance of the bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com