Lithium battery cell and lithium ion battery

A lithium battery and cell technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve problems such as lithium precipitation, lithium precipitation, and lithium precipitation in negative electrode sheets, and improve cycle stability and reliability. Safety, the ability to inhibit lithium evolution, the effect of improving the ability of lithium evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

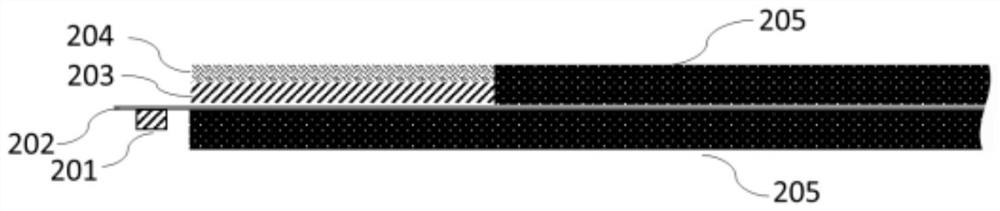

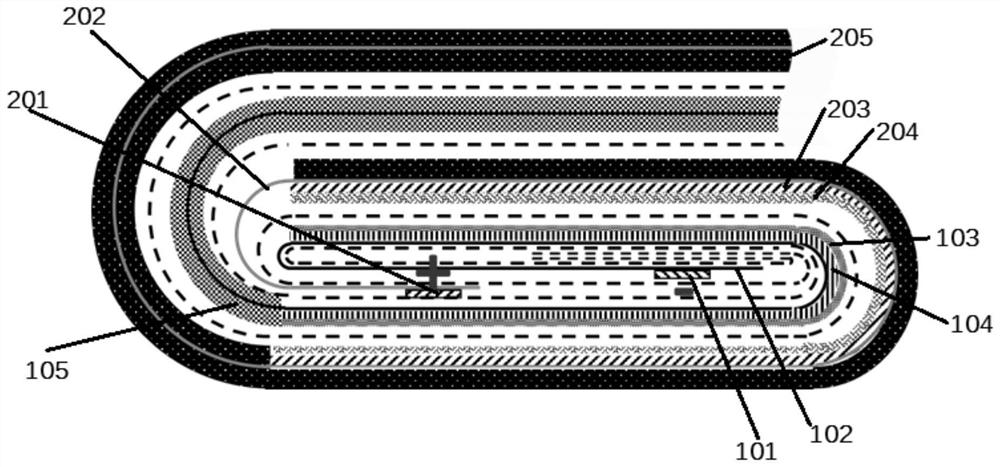

[0054]The negative electrode sheet is prepared: the slurry forming the first negative electrode active material layer is formed, and the slurry of the second negative active material layer is formed and the slurry forming the third negative active material layer; wherein the slurry of the first negative active material layer The composition was: 97 wt% graphite, 1 wt% of the conductive carbon black, 2 wt% butadiene latex, the solid content of 40% to 45 wt%; the slurry group of the second negative active material layer became: 97% by weight graphite, 1 wt % Of the conductive carbon black, 2 wt% butadiene latex, its solid content is 40% by weight to 45 wt%; the slurry group of the third negative active material layer is: 97% by weight of graphite, 1 wt% conductive carbon black, 2 wt% Butyl chlorpyrene latex, the solid content is 40% by weight to 45 wt%. D50 particle diameter (R103) of the first negative active material in the slurry of the first negative active material layer, lithium...

Embodiment 2-6 and comparative example 1-5

[0060]Example 2-6 and Comparative Example 1-5 are the same as that of the first embodiment, which differs from the first negative active substance in the slurry of the first negative active material layer (R103), Switching current density of lithium in a negative electrode active substance (i0103), the solid phase diffusion coefficient (D103) of lithium forms a D50 particle diameter (R104) of the second negative active material in the slurry of the second negative active material layer, the exchange current density of lithium in the second negative active substance ( i0104), the solid phase diffusion coefficient (D104) of lithium forms the D50 particle diameter (R105) of the third negative active material in the slurry of the third negative electrode active material layer, the exchange current density of lithium in the third negative active material ( i0105), the solid phase diffusion coefficient of lithium (D105), the negative electrode bilateral coating region length (L1034), the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com