Lithium battery negative plate, wound battery cell and lithium ion battery

A negative electrode and lithium battery technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., and can solve problems such as potential safety hazards, battery short circuits, and lithium separation on negative electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

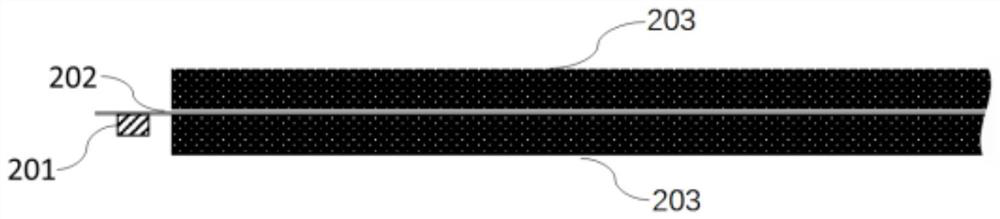

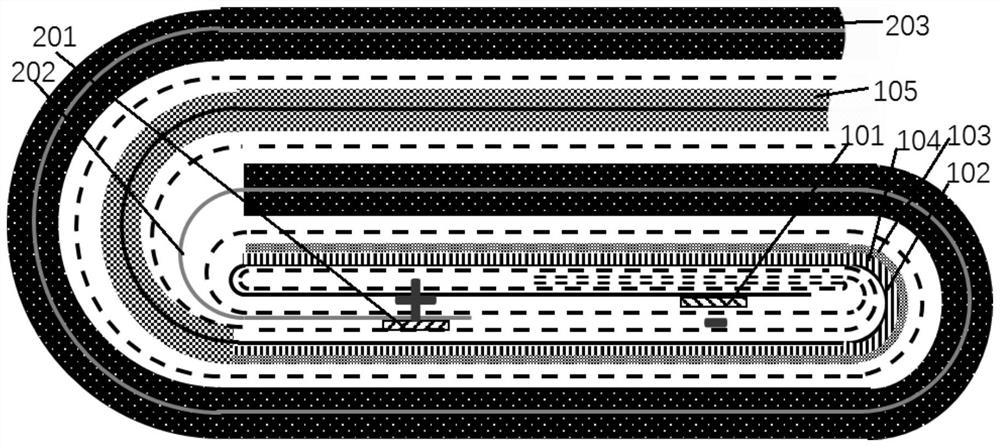

Image

Examples

Embodiment 1

[0045] Prepare the negative electrode sheet: respectively prepare the slurry forming the first negative electrode active material layer, the slurry forming the second negative electrode active material layer and the slurry forming the third negative electrode active material layer; wherein, the slurry of the first negative electrode active material layer The composition is: 97wt% of graphite, 1wt% of conductive carbon black, 2wt% of styrene-butadiene latex, and its solid content is 40wt%-45wt%; the slurry composition of the second negative electrode active material layer is: 97wt% of graphite, 1wt% % conductive carbon black, 2wt% styrene-butadiene latex, and its solid content is 40wt%-45wt%; the slurry of the third negative electrode active material layer consists of: 97wt% graphite, 1wt% conductive carbon black, 2wt% The styrene-butadiene latex has a solid content of 40wt%-45wt%. Form the exchange current density of lithium in the first negative electrode active material in t...

Embodiment 2-7 and comparative example 1-5

[0050] Embodiment 2-7 and comparative example 1-5 are identical with embodiment 1 preparation steps, form the exchange current density (i 0 103), forming the exchange current density of lithium in the second negative electrode active material in the slurry of the second negative electrode active material layer (i 0 104) and the exchange current density (i 0 105) as shown in Table 1.

[0051] Double layer coating area length (L1034), the length (L105) of the 3rd negative electrode active material layer, the first negative electrode active material layer thickness (T103), the 2nd negative electrode active material layer thickness (T104) and the 3rd negative electrode active material layer The thickness (T105) is shown in Table 1.

[0052] Table 1

[0053]

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com