Xinyang 10# black tea and processing method thereof

A processing method and technology of black tea, applied in Xinyang No. 10 black tea and its processing field, can solve problems affecting the sales and drinking of Xinyang black tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

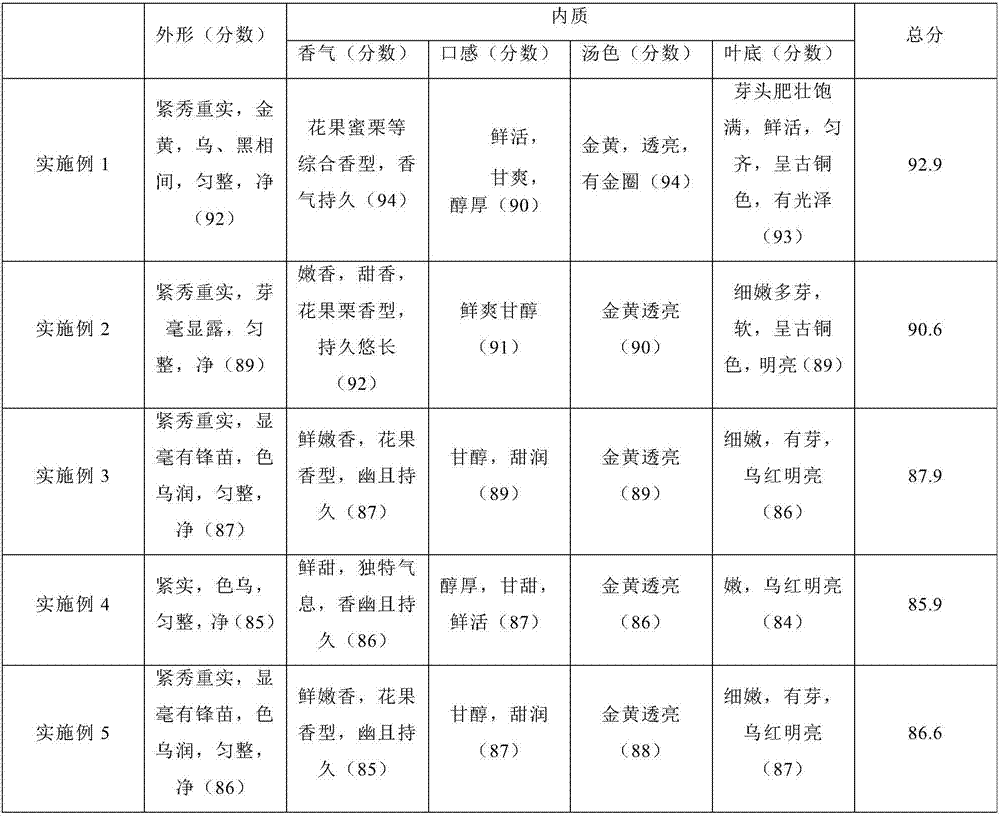

Examples

Embodiment 1

[0023] A processing method of Xinyang No. 10 black tea, comprising the following steps:

[0024] Grading According to the picking standards, the fresh leaves of Xinyang No. 10 are graded, and the bud head, one bud and one leaf, one bud and two leaves, and one bud and three and four leaves are separated;

[0025] Withering: 1.0kg / m according to the amount of spread leaves 2 , spread the buds to a thickness of 2-3cm, wither in the sun, stir once every 10min, and wither for 20min to obtain the withered semi-finished product to obtain the withered semi-finished product; Next, the withered semi-finished product is withered for 12 hours to obtain withered leaves with dark green softness, soft hand grip, dull leaf surface, continuous stalk folds, diminished freshness and a slight fragrance;

[0026] Kneading: Knead the withered leaves for 40 minutes at a temperature of 22 to 26°C and a relative humidity of 97%, dissolve the lumps formed by kneading, pass through a 3-mesh sieve, and ...

Embodiment 2

[0030] A processing method of Xinyang No. 10 black tea, comprising the following steps:

[0031] Grading According to the picking standards, the fresh leaves of Xinyang No. 10 are graded, and the bud head, one bud and one leaf, one bud and two leaves, and one bud and three and four leaves are separated;

[0032] Withering: 0.6kg / m according to the amount of spread leaves 2 , spread out one bud and one leaf to a thickness of 2-3 cm, wither in the sun, stir once every 20 minutes, and wither for 60 minutes to obtain the withered semi-finished product; then at a temperature of 28-30 ° C and a relative humidity of 60 % under the condition of withering the semi-finished product for 10 hours to obtain withered leaves with dark green softness, soft hand grip, dull leaf surface, continuous stalk folds, diminished freshness and slight fragrance;

[0033] Knead at a temperature of 22 to 26°C and a relative humidity of 93%, knead the withered leaves for 35 minutes, dissolve the agglomera...

Embodiment 3

[0037]A processing method of Xinyang No. 10 black tea, comprising the following steps:

[0038] Grading According to the picking standards, the fresh leaves of Xinyang No. 10 are graded, and the bud head, one bud and one leaf, one bud and two leaves, and one bud and three and four leaves are separated;

[0039] Withering: 0.8kg / m according to the amount of spread leaves 2 , spread out one bud and two leaves until the thickness is 2-3cm, carry out withering in sunlight, turn over once every 15min, and wither for 45min to obtain the withered semi-finished product; then at a temperature of 28-30°C and a relative humidity of 65 % under the condition of withering the semi-finished product withering for 11 hours to obtain the withered leaves with dark green softness, like cotton in the hand, dull leaves, continuous stalk breaks, diminished freshness and slight fragrance;

[0040] Knead at a temperature of 22 to 26°C and a relative humidity of 95%, knead the withered leaves for 35 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com