Frozen beverage containing granular substances or sliced substances and production technology of frozen beverage

A frozen drink and production process technology, applied in dairy products, food science, milk preparations, etc., can solve problems such as poor sensory effects and different visual impacts for consumers, and achieve the effect of meeting the needs of nutrition and health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A frozen drink containing slices, comprising a frozen drink body and slices adhered or embedded on the surface of the frozen drink body.

[0074] The flakes are fresh fruit slices, and the thickness of the fruit slices is 1-3mm.

[0075] The flakes are selected from the granules or flakes of one or more fresh fruits in strawberry, kiwi fruit, carambola, pineapple and yellow peach.

[0076] The production process of the above-mentioned frozen drink containing sheet is as follows:

[0077] 1. The production process of the used fresh fruit chips is as follows:

[0078] Fresh fruit → wash and remove inedible parts → rapid blanching and sterilization (85°C, 30 seconds) → slice (thickness 1-3mm) → set aside.

[0079] 2. The technology of adopting above-mentioned fresh fruit slices to prepare frozen drinks is as follows:

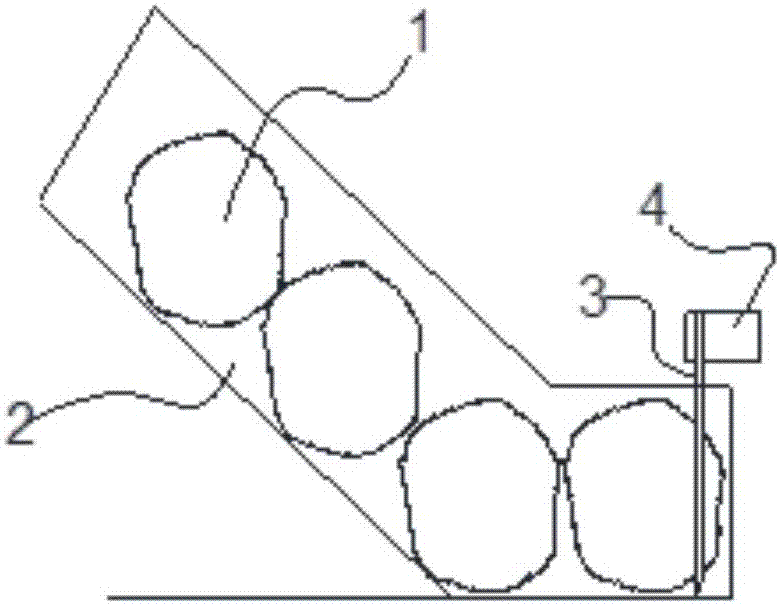

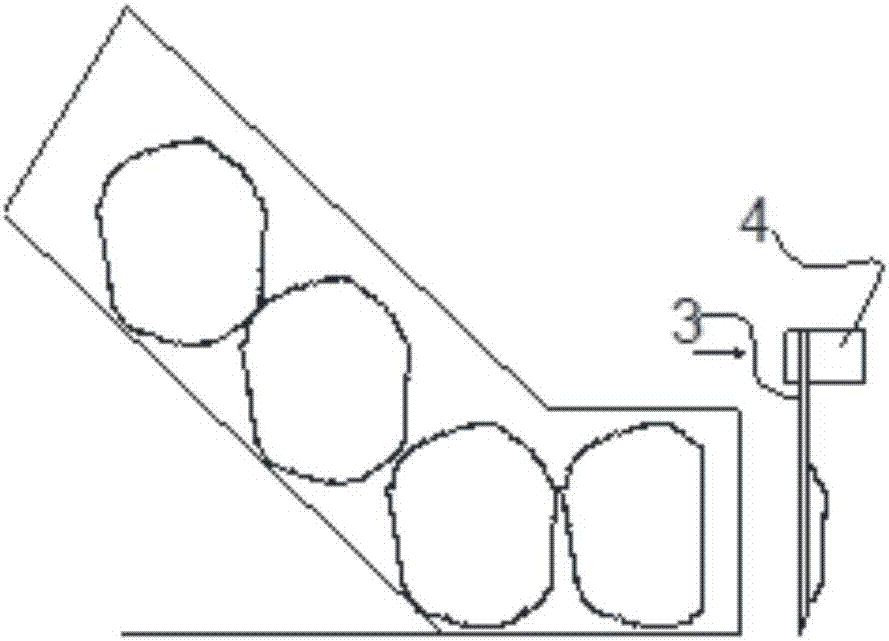

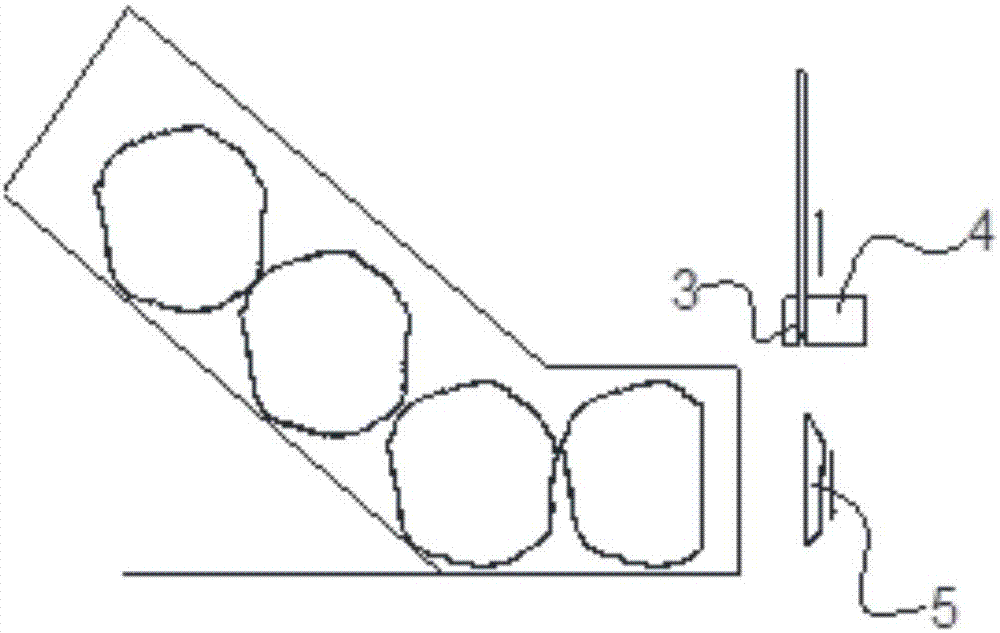

[0080] Fill the mold with sterilized drinking water → put fruit slices (preferably one piece in each mold) → insert the slurry suction trolley into the b...

Embodiment 2

[0092] A frozen drink containing particles includes a frozen drink body and particles adhered or embedded on the surface of the frozen drink body.

[0093] The particles are fresh fruit grains, and the size of the fruit grains is 8*8*8-15*15*15mm.

[0094] The fruit pieces are selected from fruit pieces of one or more fresh fruits in strawberry, kiwi fruit, carambola, pineapple and yellow peach.

[0095] The production process of the above-mentioned frozen drink containing particles or flakes is as follows:

[0096] 1. The production process of the fresh fruit granules used is as follows:

[0097]Fresh fruit → wash and remove inedible parts → rapid blanching and sterilization (85°C, 30 seconds) → diced (8*8*8mm—15*15*15mm) → spare

[0098] 2. The technology of adopting above-mentioned fresh fruit grain to prepare frozen drink is as follows:

[0099] The mold is filled with sterilized drinking water → put in fruit pellets → insert the slurry suction trolley into the bottom o...

Embodiment 3

[0113] A frozen drink containing flakes, the preparation process of which is similar to that of Example 1, except that the flakes are honey-soaked fruit slices, and its test effect is compared with that of the product in Example 1, except that the fruit Except freshness descends to some extent, all the other test effects are similar to the product of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com