Planetary speed increasing mechanism device with internally-arranged spindle

A speed-increasing mechanism and planetary technology, which is applied in the field of machine tools, can solve the problems of affecting the sealing effect, affecting the life of the bearing, and the wear of the seal, so as to achieve the effects of avoiding leakage, high transmission efficiency, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

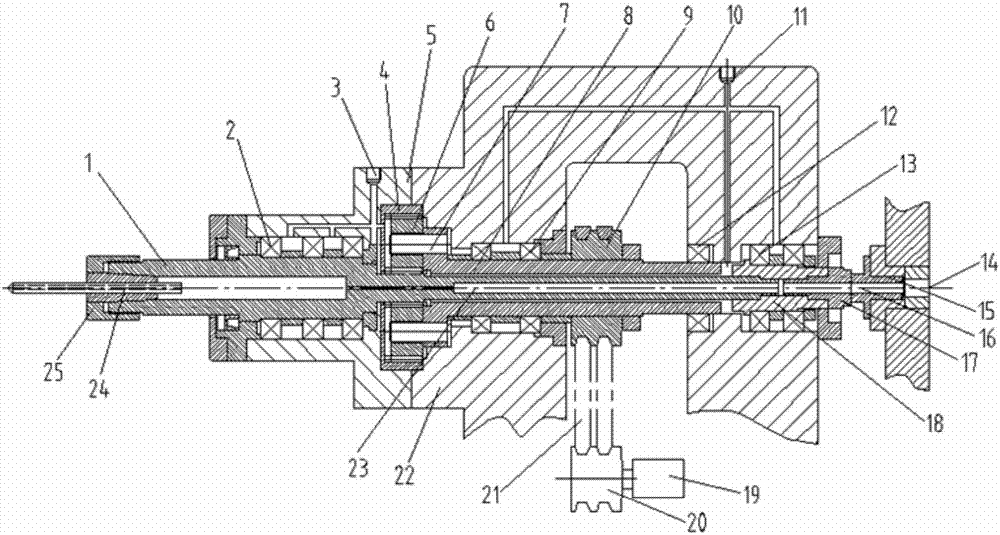

[0014] Such as figure 1 As shown, the planetary speed-up mechanism device with a built-in main shaft of the present invention has a driven shaft 1, a bearing 2, a lubrication hole 3, a ring gear 4, a casing 5, a planetary gear 6, a driving pin 7, a driving shaft 8, a bearing 9, Driven pulley 10, lubrication hole 11, bearing 12, bearing 13, coolant supply hole 14, rotary connector 15, rotary connector stationary side member 16, rotary connector rotary side member 17, connecting member 18, motor 19, Drive pulley 20, belt 21, casing 22, cooling hole 23, rotary tool 24 and cap nut 25, etc., the specific structure is as follows:

[0015] The drive shaft 8 is supported by two sets of bearings (bearing 9 and bearing 12) fixed in the casing 22, the driven pulley 10 is fixed on the drive shaft 8, the motor 19 drives the drive pulley 20 to rotate, and the drive pulley 20 passes through the belt 21 The driven pulley 10 is driven to rotate, and the driven pulley 10 drives the drive shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com