Green pulp bleaching technology

A technology of pulp and process, applied in the field of green bleached pulp process, which can solve the problems of poor hydrogen peroxide bleaching effect, complicated process and high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

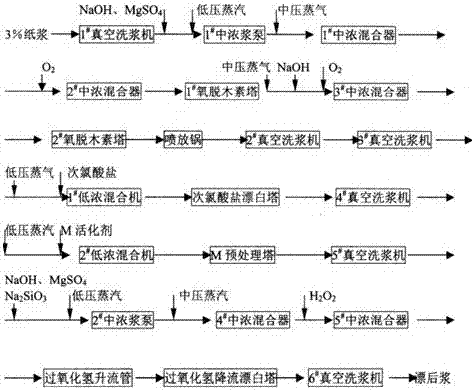

[0005] combine figure 1 , the more detailed flow process of the inventive method comprises the following steps: a kind of green bleaching pulp process is characterized in that comprising the following steps: the present invention uses non-polluting oxygen and hydrogen peroxide to clean the bleaching agent, through single-stage double-tower oxygen bleaching and activation Pretreatment to achieve high-efficiency bleaching, the activator is sulfite anhydride, cisic anhydride, mannan, succinic anhydride, phthalic anhydride or maleic anhydride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com