Offshore wind power construction process

An offshore wind power and construction technology technology, applied in wind power generation, wind turbine assembly, installation/support of wind turbine configuration, etc., can solve the problem of lack of supporting ship process, achieve clear division of labor, prevent accidents, and improve construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

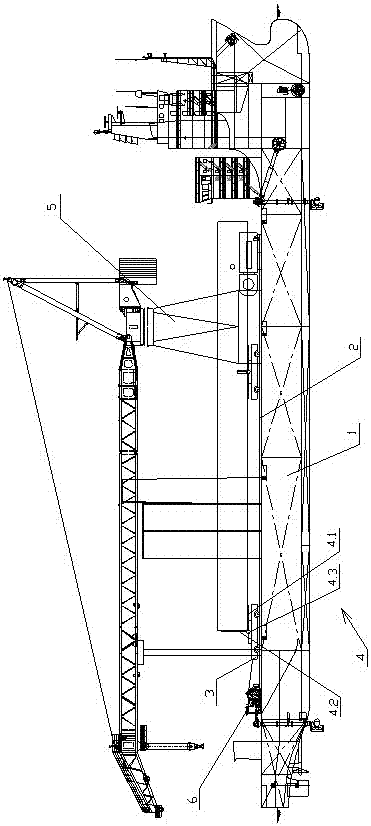

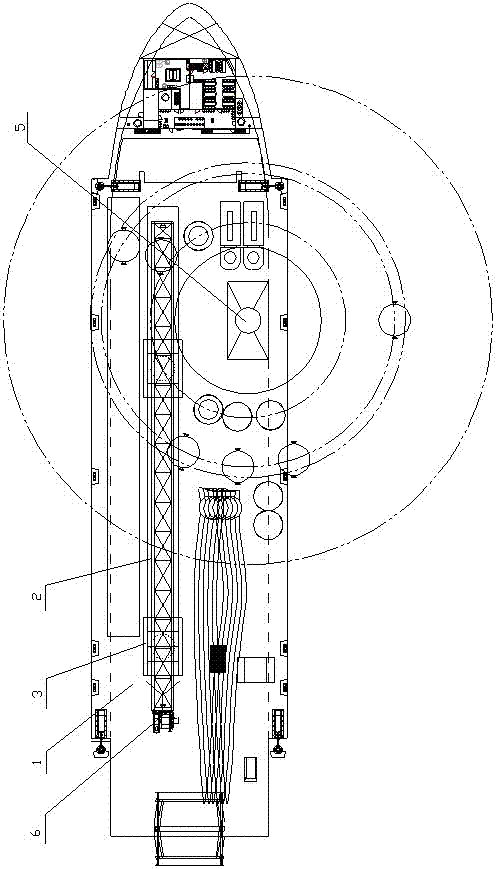

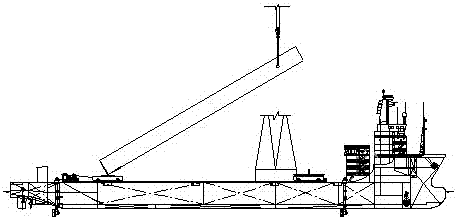

[0031] see Figure 1~9 , an offshore wind power construction process related to the present invention, the offshore wind power construction process adopts an offshore wind power construction ship, the construction ship includes a hull 1, a crane 5 is installed on the deck of the hull 1, and the A track 2 is arranged on the deck of the hull 1, and a sliding trailer 3 is slidably arranged on the track 2, and a rotating pallet 4 is installed on the sliding trailer 3, and the rotating pallet 4 includes a horizontal plate 4.1 and a vertical plate 4.2 , the horizontal plate 4.1 and the vertical plate 4.2 form an L-shaped structure, and a rotating shaft 4.3 is installed at the junction of the horizontal plate 4.1 and the vertical plate 4.2, and the rotating shaft 4.3 is erected on the sliding trailer 3, so that it is placed on the rotating pallet 4 The steel piles can be rotated during hoisting; a hoist 6 is installed on the deck of the hull 1, and the ropes wound on the hoist 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com