Water tank type cleaning machine

The technology of a water tank cleaning machine and a water tank body is applied in the field of cleaning machines, which can solve the problems of reduced water circulation efficiency, easy accumulation of dirt on the filter, affecting the spray effect, etc., and achieves smooth water circulation, large filter area, and improved cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

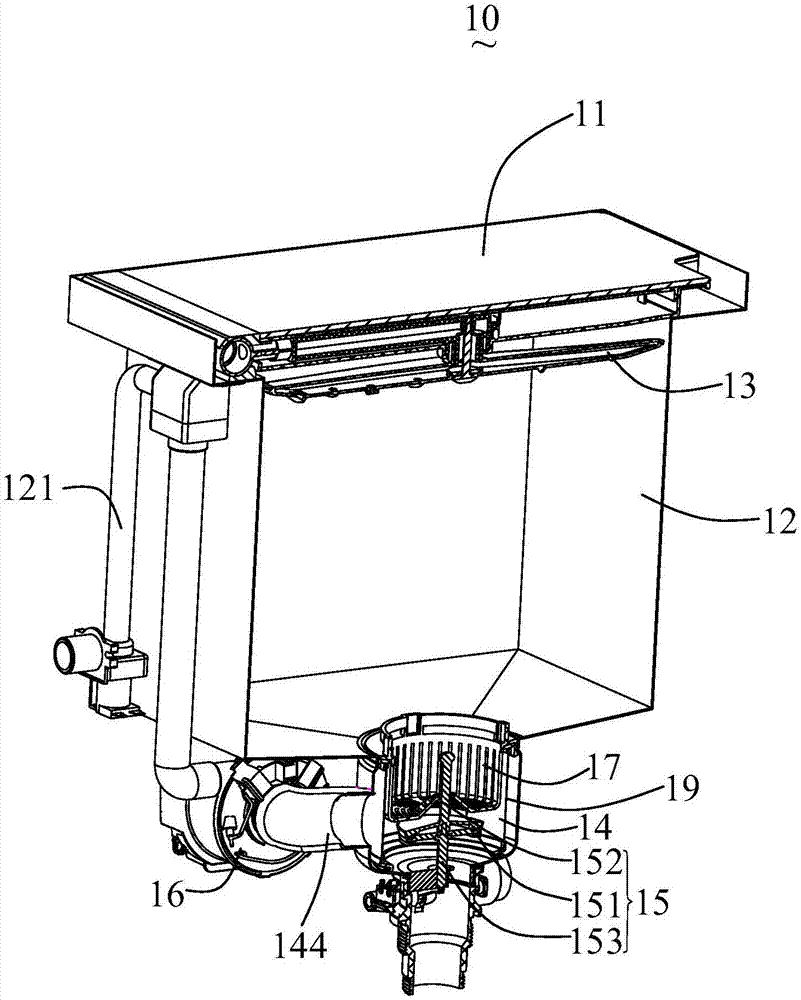

[0040] see figure 1As shown in the first preferred embodiment of the sink type cleaning machine of the present invention, the sink type cleaning machine 10 includes a cover body 11 and a sink body 12, the cover body 11 and the sink body body 12 form a cleaning space, and the cover body 11 is An upper spray arm 13 is provided, and the spray arm 13 can freely rotate around the central axis of the tank body 12 under the cover 11. The bottom of the tank body 12 is provided with a drainer 14. Water pipe 121, the water inlet pipe 121 supplies water to the upper spray arm 13, so as to realize spray cleaning at the same time of water intake, improve cleaning efficiency and shorten the cleaning cycle.

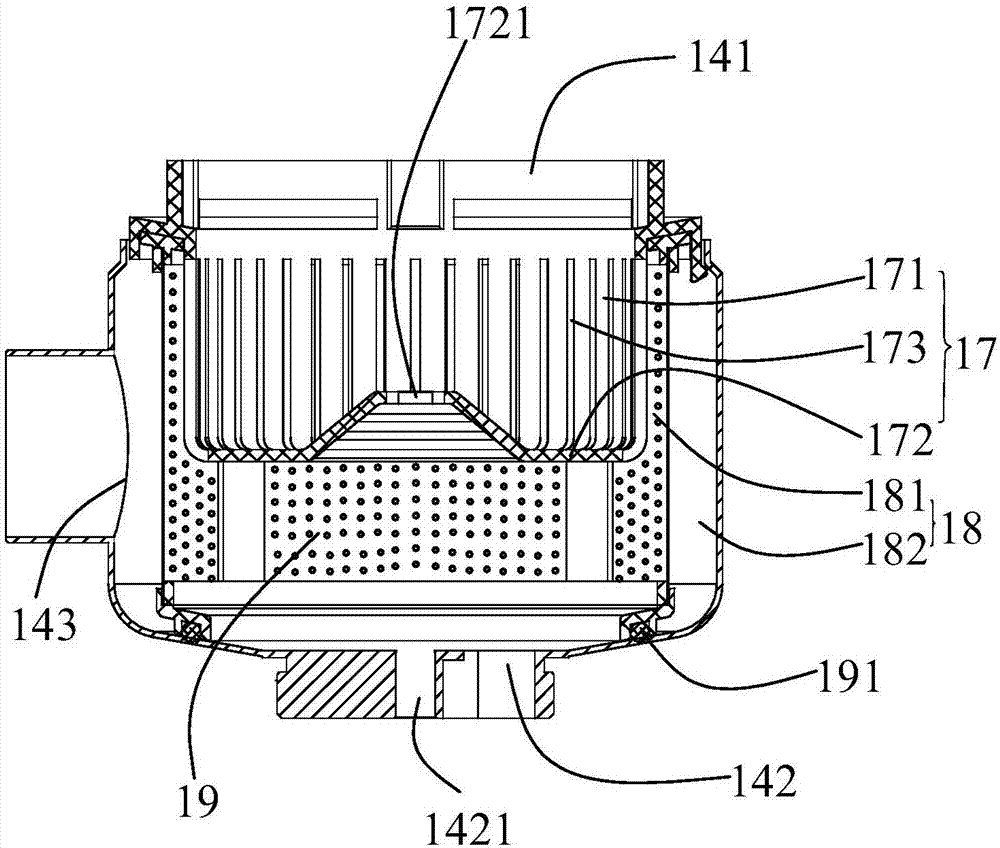

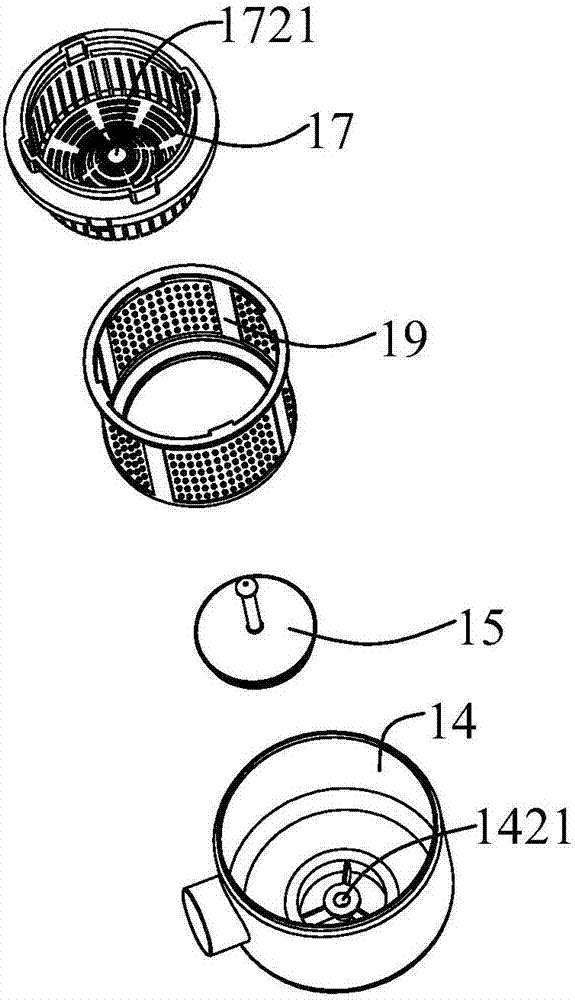

[0041] Please also refer to figure 2 and image 3 , the top of the drainer 14 is open to form a water inlet 141, the water inlet 141 communicates with the tank body 12; the bottom is provided with a drain 142, and the drain 142 is provided with a drain valve 15, and the drain valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com