Adjustable Spraying Equipment

A spraying equipment and adjustable technology, applied in the direction of spraying devices, etc., can solve the problems of low spraying processing efficiency, etc., and achieve the effects of convenient batch spraying processing, novel structural design, and improved efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

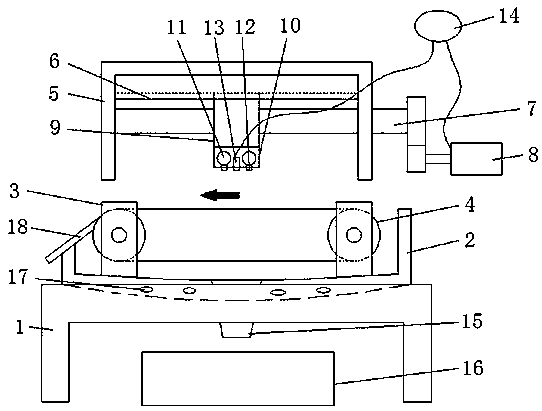

[0013] See attached picture:

[0014] Adjustable spraying equipment, including a frame 1, an upwardly open box 2 is installed on the upper end of the frame 1, and support frames 3 arranged at intervals are installed on the bottom of the box body 2, and conveyor belts are horizontally arranged between the support frames 3 4; The top of the conveyor belt 4 is provided with a protective cover 5 that is open downward, and a guide rail plate 6 is installed on the top wall of the protective cover 5, and a screw rod 7 parallel to it is installed on the inner wall of the protective cover below the guide rail plate 6. 7. One end protrudes from the protective cover and connects with the output shaft of the forward and reverse motor 8 through the gear pair. The screw rod 7 is screwed with a sliding seat 9, and the upper end of the sliding seat 9 is slidably installed in the track groove of the guide rail plate 6. The sliding seat 9 The lower end of the fixed seat 10 is equipped with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com