Method for eliminating horizontal flight resistance of vertical takeoff and landing aircraft rotor

A vertical take-off and landing, aircraft technology, applied in the field of aircraft, can solve problems such as resistance and vibration, achieve smooth transition, simplified flight control, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

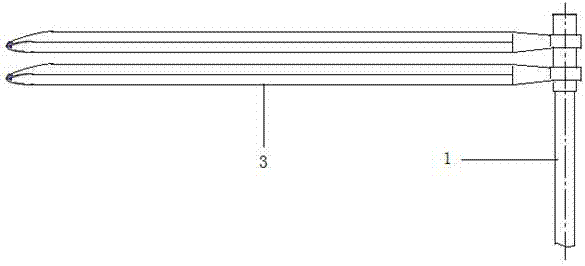

[0034] Embodiment 1: The method for eliminating the horizontal flight resistance of the vertical take-off and landing aircraft rotor is: adopt a group of rotor blades that can be fully deployed and fully retracted in flight, and allow the rotor blades to rotate positively with the drive shaft when the aircraft takes off and lands , so that all the blades are fully expanded to generate the maximum lift. When the aircraft is flying horizontally, the rotor blades are fully retracted and deformed into a shape with little air resistance. The centrifugal force and aerodynamic force are used to automatically adjust the rotor blades according to the flight conditions. The working state of the vertical take-off and landing aircraft eliminates the horizontal flight resistance of the rotor. The rotor blades automatically open and close according to the flight conditions. When the aircraft takes off and lands vertically, the centrifugal force of the drive shaft is used to drive the rotor b...

Embodiment 2

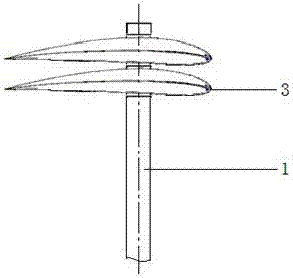

[0037] Embodiment 2: The method for eliminating the horizontal flight resistance of the vertical take-off and landing aircraft rotor is: adopt two groups of rotor blades with opposite directions of rotation and can fully expand and fully retract in flight, and allow the two groups of rotor blades to rotate when the aircraft takes off and lands. With the positive rotation of the drive shaft, all the blades are fully expanded to generate the maximum lift. When the aircraft is flying horizontally, the two sets of rotor blades are completely retracted and deformed into a shape with little air resistance. The flight condition automatically adjusts the working state of the rotor blades to eliminate the horizontal flight resistance of the vertical take-off and landing aircraft rotor. The rotor blades automatically open and close according to the flight conditions. When the aircraft takes off and lands vertically, the centrifugal force of the drive shaft is used to drive the rotor blad...

Embodiment 3

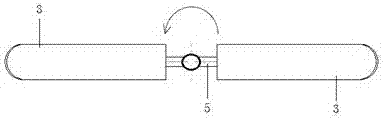

[0040]Embodiment 3: the method for eliminating the horizontal flight resistance of the vertical take-off and landing aircraft rotor is to adopt a group of rotor blades that can be expanded and retracted. The shaft rotates forward to form lift. When the aircraft is flying horizontally, a group of blades of the retractable rotor are retracted in reverse to reduce air resistance and act as a fixed wing. The working state of the retractable rotor is automatically opened and closed according to the flight conditions. When the aircraft takes off and lands, the drive shaft drives a group of blades of the retractable rotor to automatically expand and rotate forward with the drive shaft. When flying, the drive shaft is locked to use the head-on A set of blades of the retractable rotor is reversely retracted by the blowing of the airflow. In the case of an emergency crash of the aircraft, the retractable rotor blades spin and expand in the positive direction under the blowing of the upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com