Sewing machine automatic trimming control device and method

A control device and a sewing machine technology, which are applied to the thread cutting mechanism, sewing machine components, sewing equipment and other directions in the sewing machine, can solve the problems of unsightly, loose thread ends, and easy loose thread ends, so as to ensure the quality of thread trimming, the same length of thread ends, The length of the thread is short and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

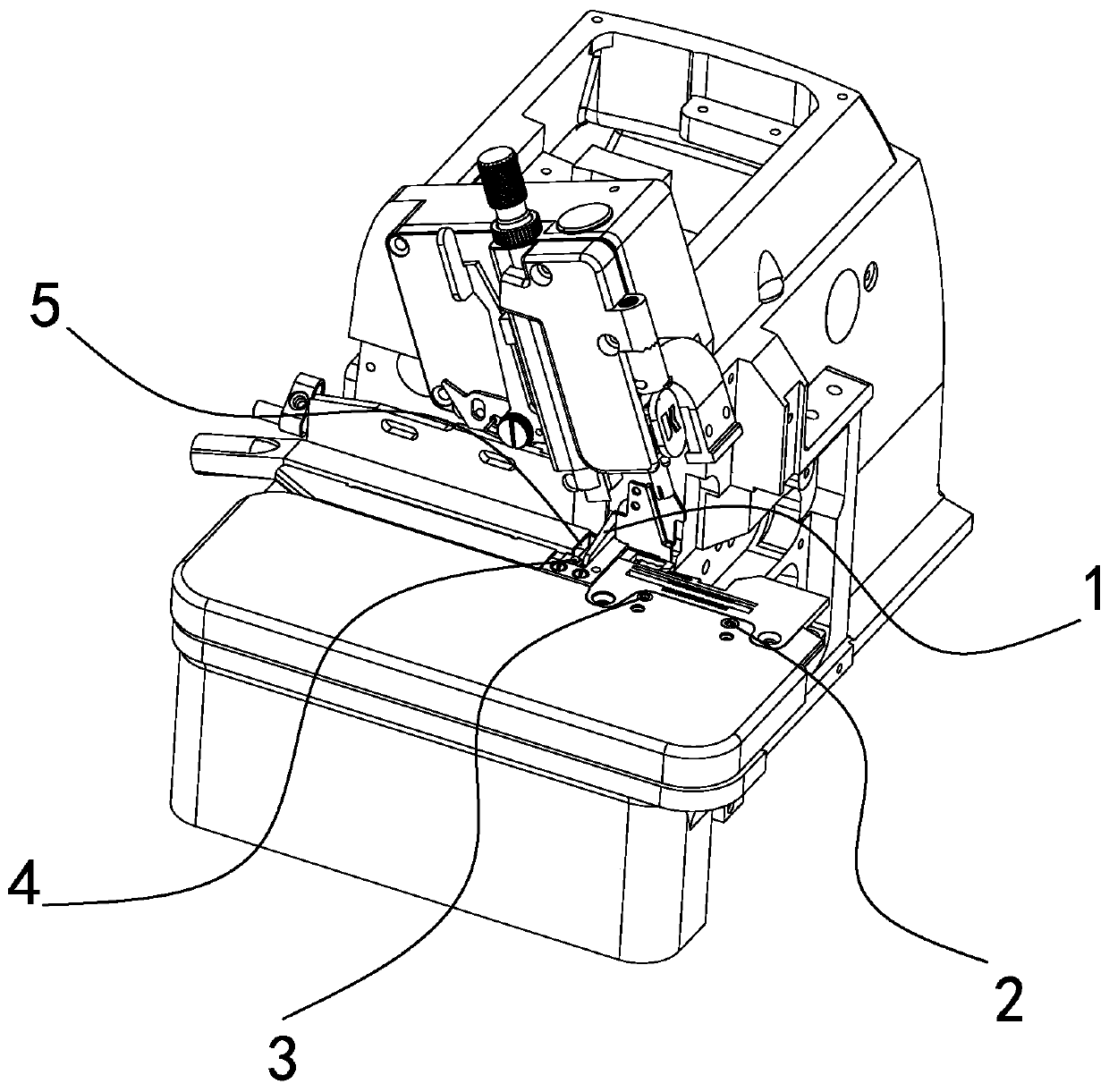

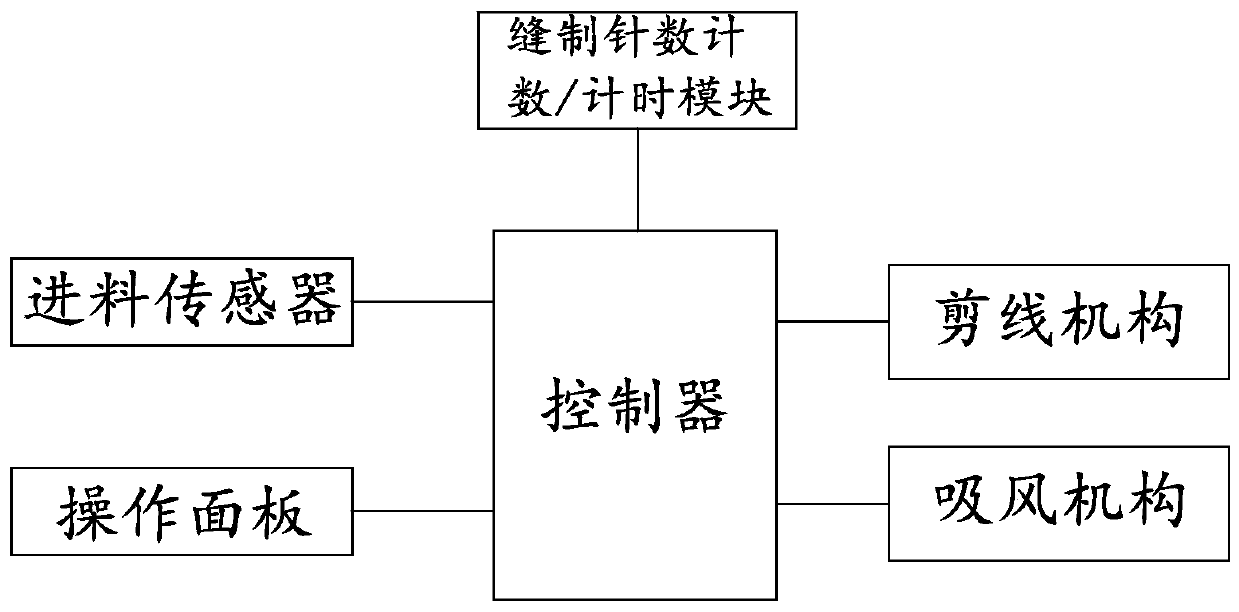

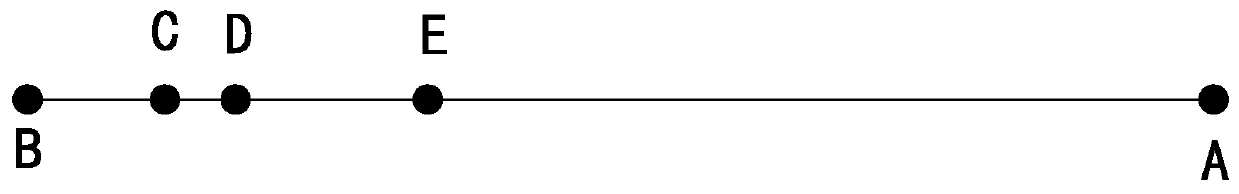

[0044] Such as figure 1 and 2 As shown, the automatic thread trimming control device of the sewing machine includes a controller and a counting / timing sensor electrically connected to the controller, a thread trimming mechanism, a suction mechanism and a setting module. The thread trimming mechanism includes a driving source and a thread cutter 1, The controller is provided with a stitch number counting / timing module, the air suction mechanism includes an air pump and an air suction port 5, and the driving source and the air pump are connected to the controller and controlled by the controller. Of course, in addition to the above-mentioned structures, the sewing machine also includes other structures such as a motor and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com