Ultrahigh-speed and ultraprecise air static piezoelectric spindle active thermal control system and method thereof

An air static pressure, electric spindle technology, applied in general control system, control/regulation system, temperature control by electric method, etc. Improve control accuracy and robustness, realize real-time prediction, and solve the effect of temperature control delay problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

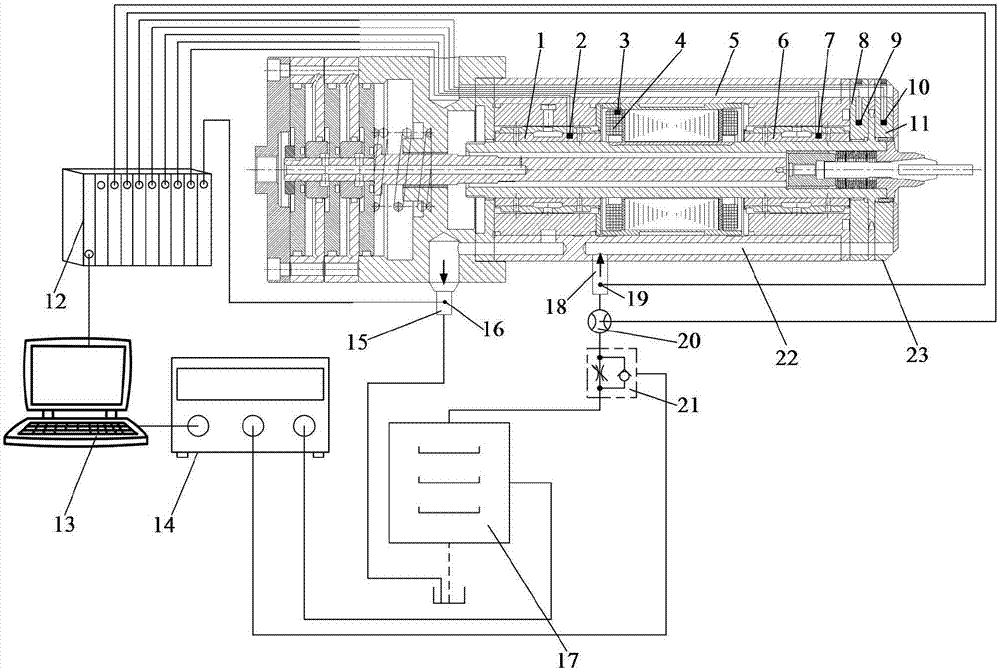

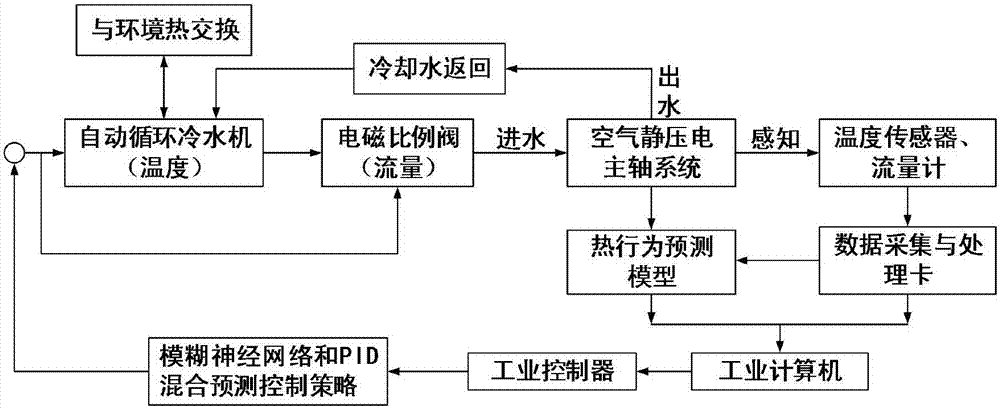

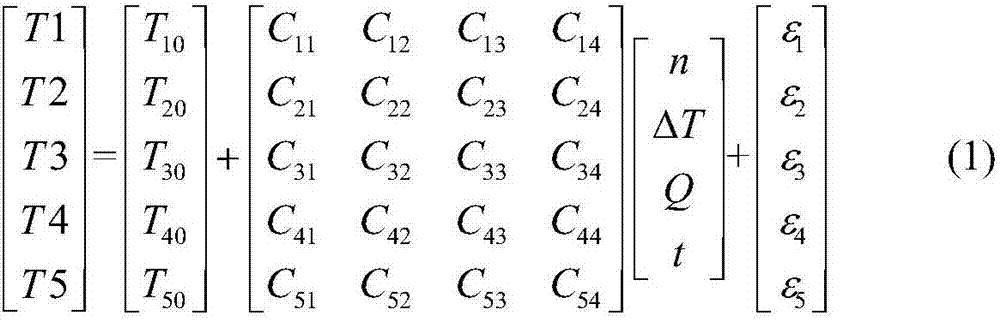

[0026] Such as figure 1 As shown, in this embodiment, an active thermal control system for an ultra-high-speed ultra-precision aerostatic electric spindle includes: a first temperature sensor 2, a second temperature sensor 3, a third temperature sensor 7, and a fourth temperature sensor 9 , the fifth temperature sensor 10, the sixth temperature sensor 16, the seventh temperature sensor 19, data acquisition and processing card 12, industrial computer 13, industrial controller 14, automatic circulation chiller 17, electromagnetic proportional valve 21, liquid flow meter 20 and cooling water 22; wherein, the automatic circulating chiller 17 itself has a water pump and a cooling system, and the maximum heat dissipation power of the automatic circulating chiller 17 is greater than the total heating power of the electric spindle, and the maximum flow rate of the automatic circulating chiller 17 is sufficient to make the electric The heat generated inside the main shaft is taken out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com