Deep sea manual hydraulic driving type disposable ballasting device

A driving and hydraulic technology, which is applied in the direction of motor vehicles, transportation and packaging, ships, etc., can solve the problems of hydraulic cylinder sealing mechanism rigidity, strength, problems, and dynamic sealing, so as to avoid the use of additional pressure compensation devices, Simplify the locking structure and avoid the effect of dynamic sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

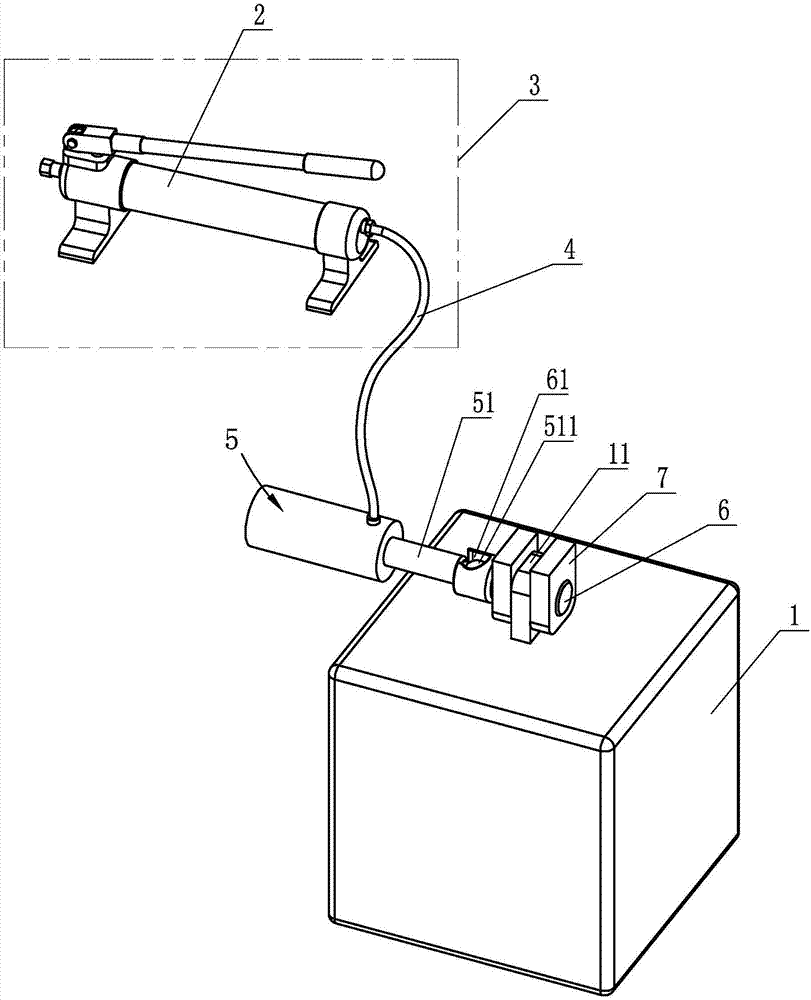

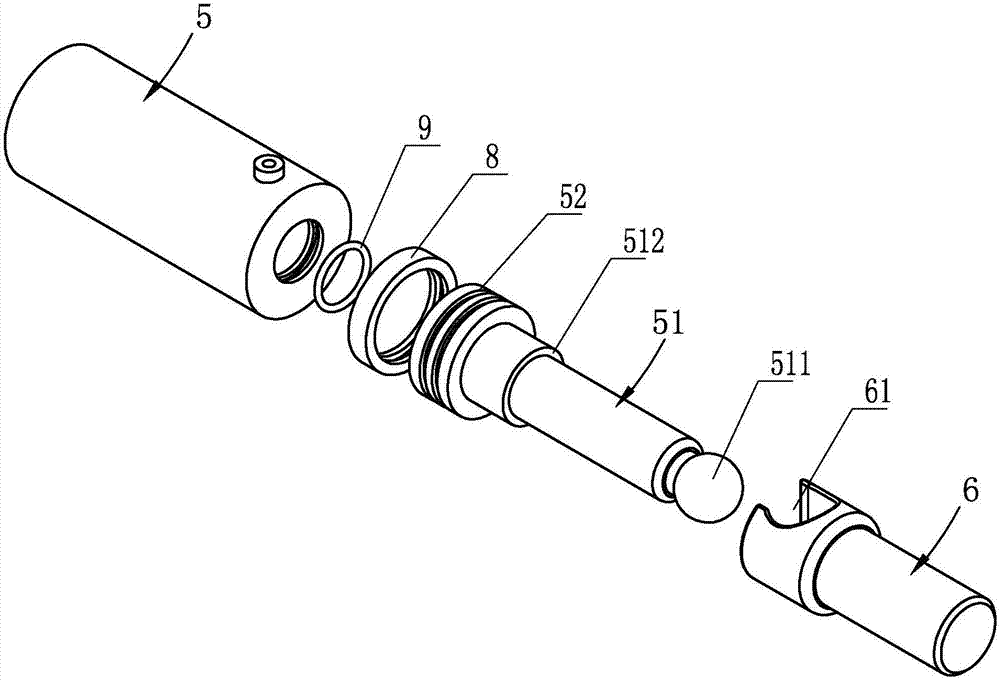

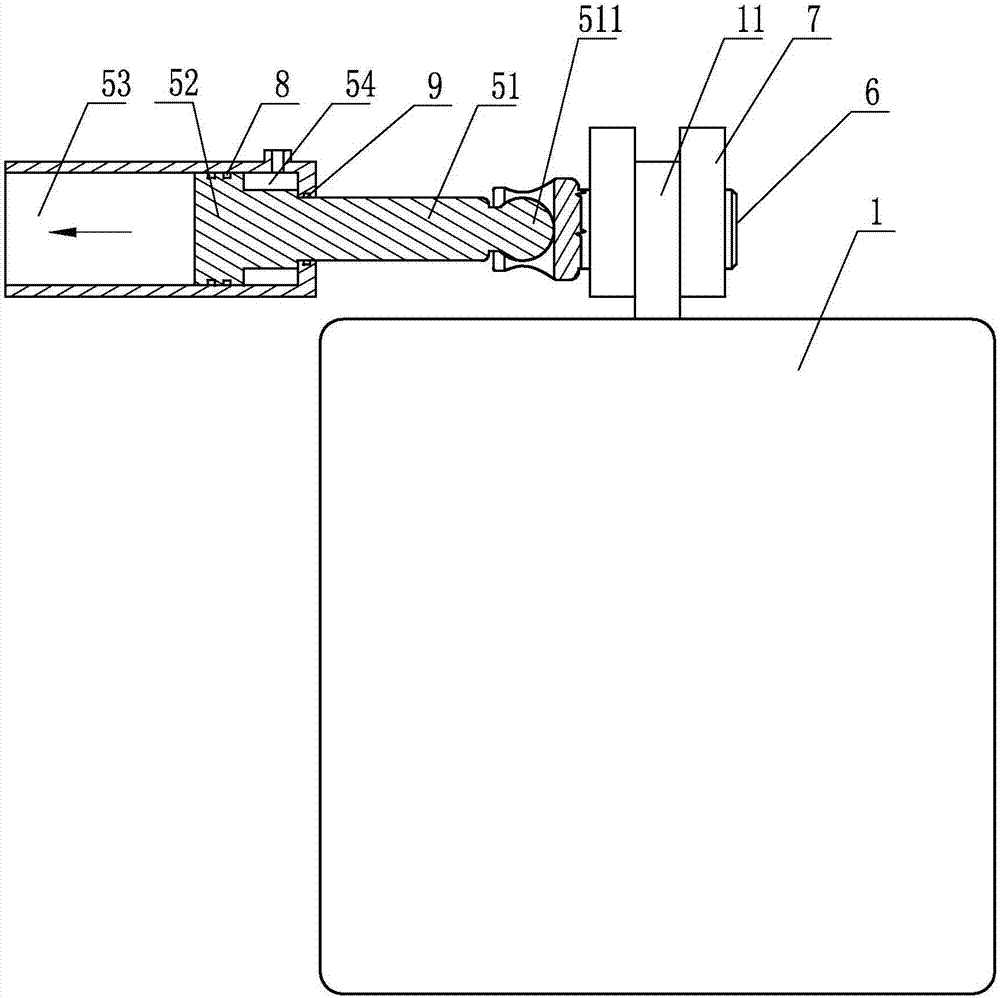

[0025] See figure 1 , the present invention includes a hydraulic drive mechanism, an executive mechanism and a ballast 1, the hydraulic drive mechanism is a manual hydraulic pump 2 arranged in a cabin body 3 of a deep-sea manned submersible, and the executive mechanism is located in the cabin body 3 The external hydraulic cylinder 5, the oil outlet of the manual hydraulic pump 2 is connected to the oil inlet of the hydraulic cylinder 5 through the tank penetration pipeline 4, the cylinder body of the hydraulic cylinder 5 is fixedly connected with the deep-sea manned submersible, and the piston of the hydraulic cylinder 5 The rod 51 is connected to the pin shaft 6 through a universal joint, which includes a ball head 511 on the head of the piston rod 51 and a groove 61 on the pin shaft 6 that matches the ball head 511; the ballast 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com