Composite materials comprising conductive nano-fillers

A technology of conductive nano fillers and compositions, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, shielding materials, nanotechnology, etc., can solve expensive problems and achieve the effect of high conductivity and dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

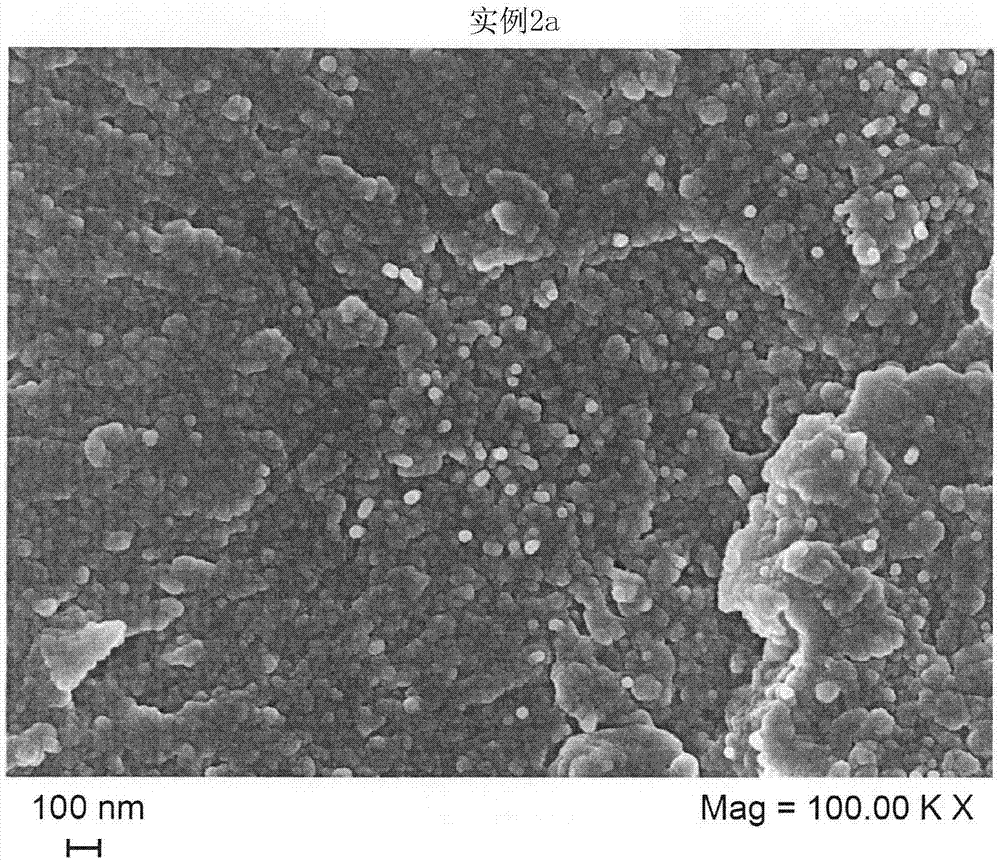

Examples

example

[0161] Measurement methods

[0162] Compositions of the invention can be characterized using the methods described below.

[0163] Conductivity

[0164] The electrical resistance (as a ratio of applied voltage to current) was recorded in the bridging method using a Burster-Resistomat 2316 milliohmmeter to determine the conductivity of cured plaques and composites. Contact is established between the two sample surfaces using a Kelvin test probe. All measurements were performed at RT and standard humidity conditions according to the 4-wire measurement method.

[0165] Resin system conductivity was measured on cured resin coupons taken from smooth uniform plaques. Characterization was performed on square coupons (side length = 40 mm ± 0.1 mm) approximately 3 mm thick. Two electrodes were established on opposing coupon surfaces using commercially available silver paste.

[0166] The composite z-direction conductivity was measured on coupons taken from defect-free panels m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com