Direct-drive swing gate machine core

A core and direct drive technology, applied in the direction of power control mechanism, wing leaf control mechanism, door/window accessories, etc., can solve the problems of high failure rate, short life, high cost, etc., to increase the service life and reduce production costs , noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

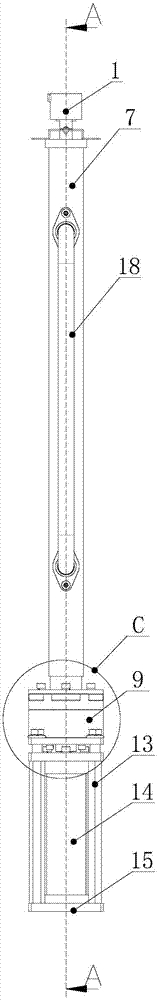

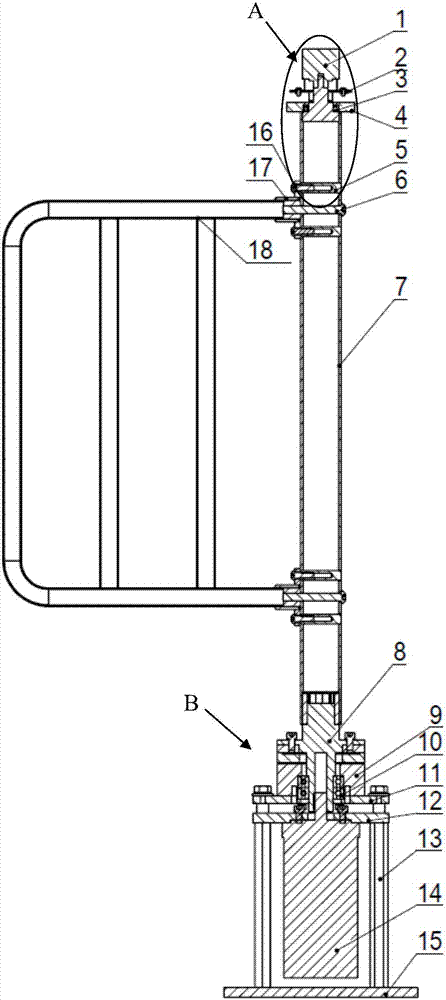

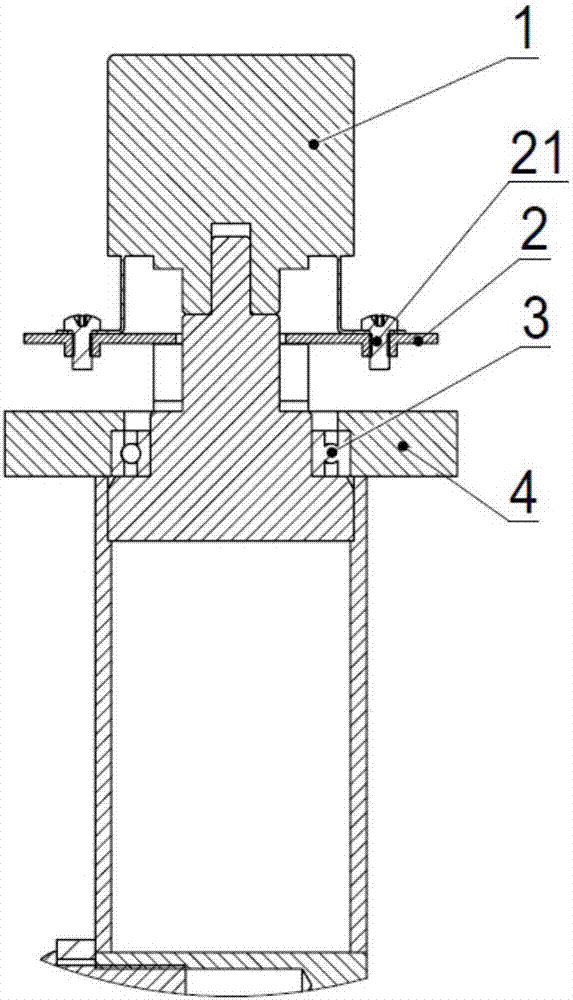

[0022] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0023] Such as Figure 1-Figure 5 As shown, a direct-drive swing gate movement of the present invention includes a gate post 7 installed in the gate, a swing door 18 mounted on the gate post 7 and a mechanism for driving the gate post 7 to drive the swing gate 18 to rotate. Drive mechanism, the connection between the door post 7 and the swing door 18 is provided with a door post thread fixing shaft 5, a door swing fixing bolt 6, a connecting flange assembly 17 and a connecting flange fixing bolt 16, the swing door 18 is connected to The flange assembly 17 is connected and locked through the door swing fixing bolt 6 passing through the door post 7. The connecting flange assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com