An array type dynamic dispersion solid phase extraction device and extraction method

A technology for dispersing solid-phase and extraction devices, which is applied in measurement devices, material separation, and analysis of materials, etc., can solve the problems of filling uniformity affecting the efficiency of solid-phase extraction, unsatisfactory repeatability between samples, and non-compliance with sustainable development. Achieve the effect of reducing extraction time, saving maintenance costs, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

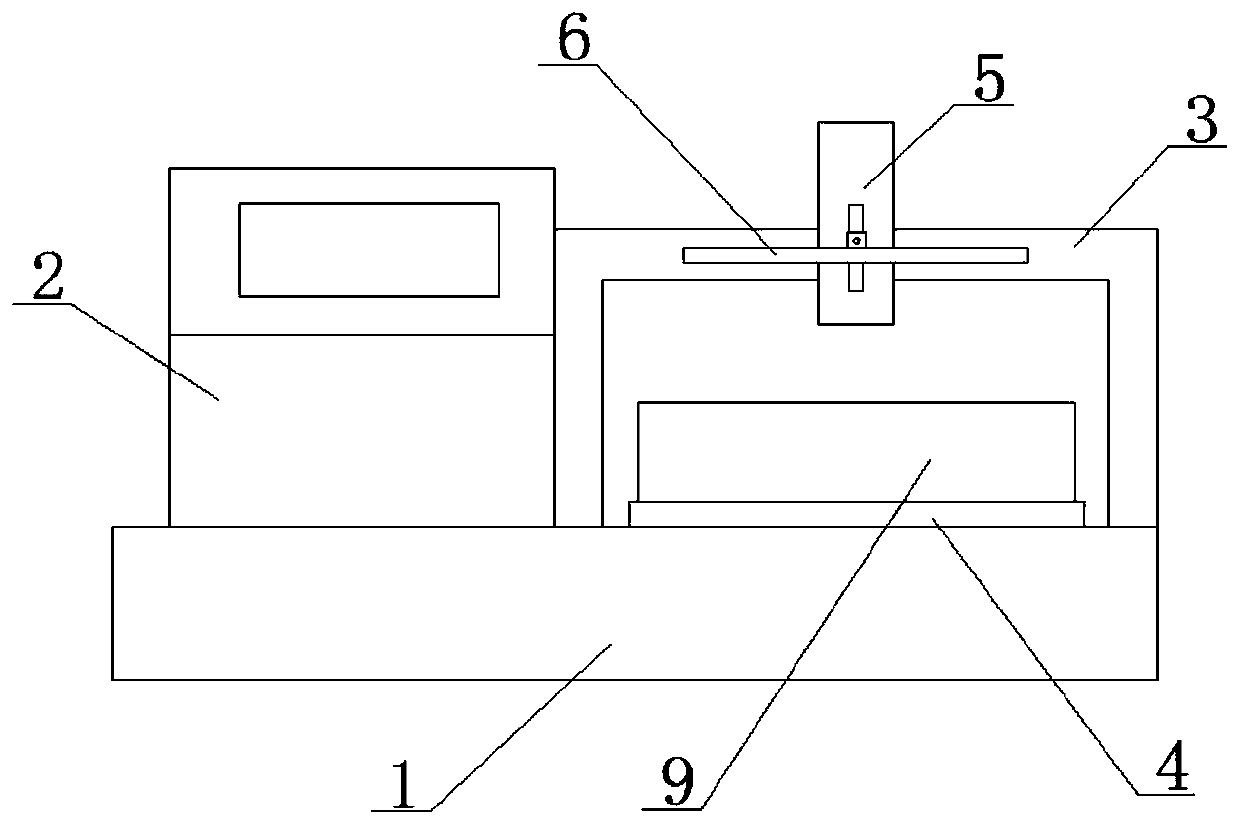

[0044] Such as figure 1 Shown, a kind of array type dynamic dispersive solid-phase extraction device comprises a base housing 1, a controller 2, a gantry 3, a tray 4, a longitudinal housing 5 and a loading plate 6 for carrying a liquid aspirator; the tray 4 is detachably connected with a disc changer 9; the gantry 3 is fixedly connected to the base shell 1, and the longitudinal shell 5 is longitudinally arranged and fixedly connected to the gantry 3;

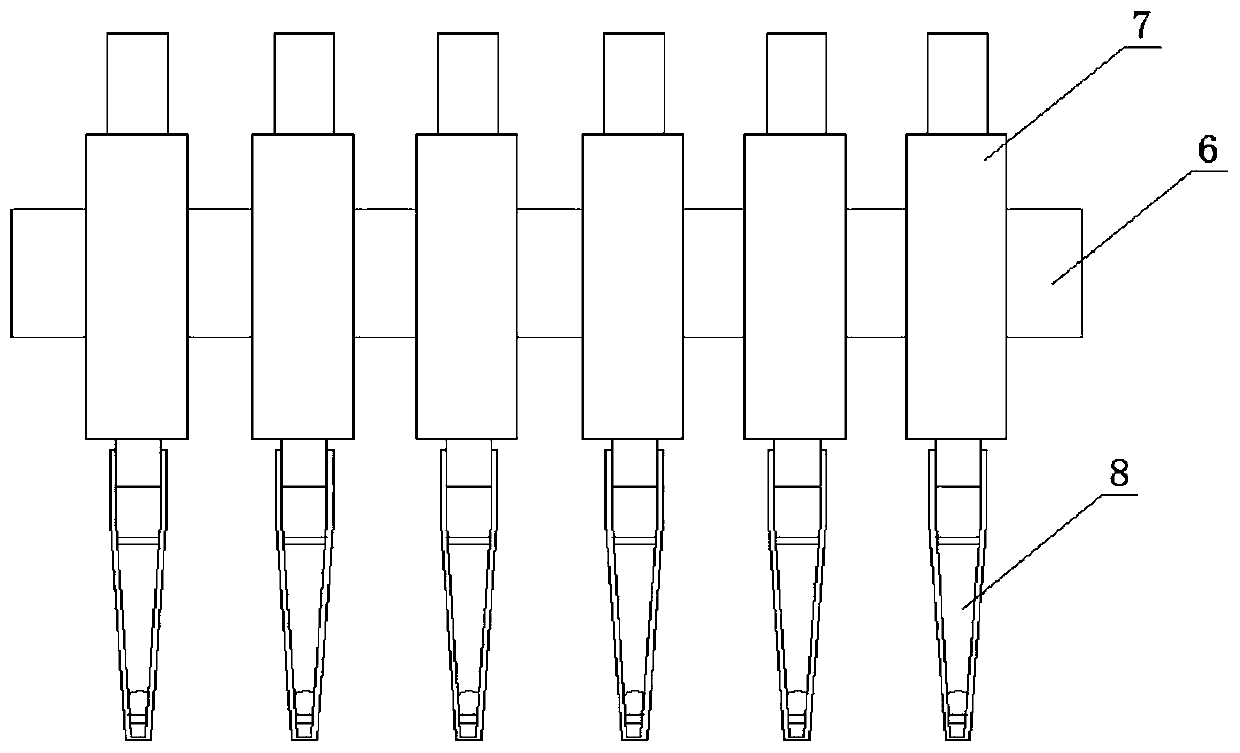

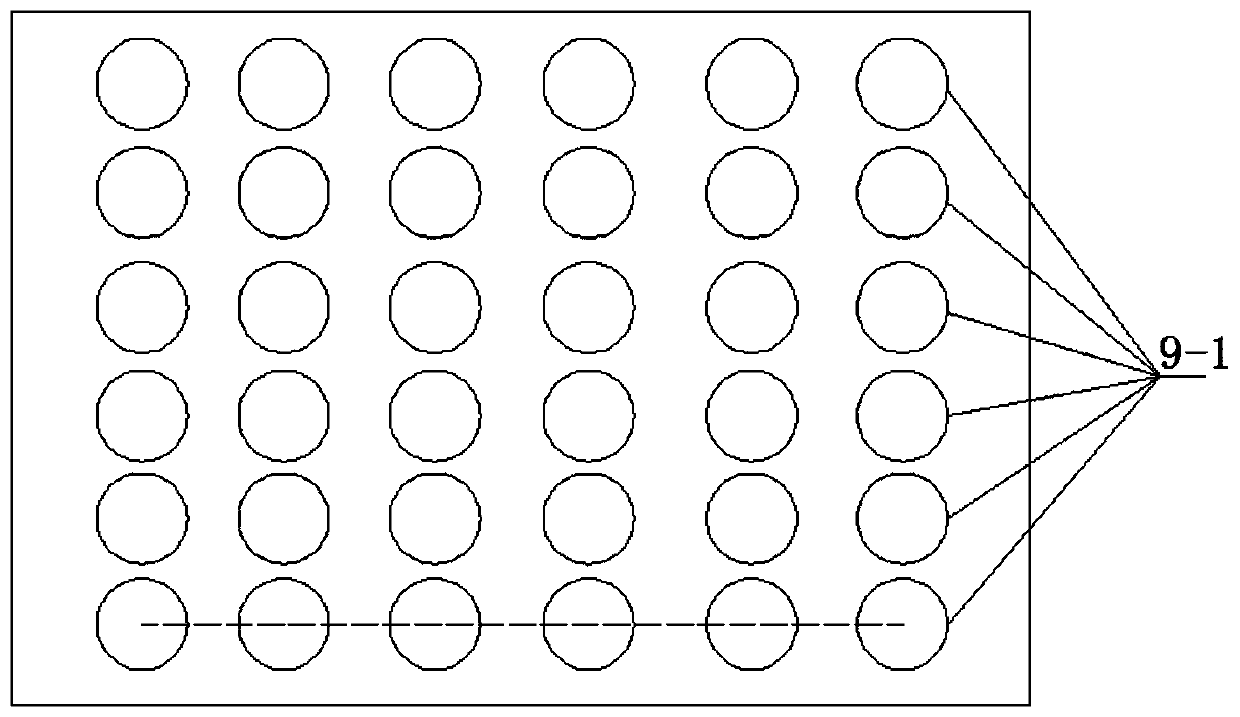

[0045] Such as figure 2 and image 3 As shown, several rows of carrying holes 9-1 are set on the disc changer 9, and each row of carrying holes 9-1 has several; several electric liquid aspirators 7 are set on the carrying plate 6, and each row of carrying holes 9-1 The quantity of -1 is the same as that of the electric pipette 7; the electric pipette 7 is equipped with an extraction tip 8;

[0046] The inside of the carrying hole 9-1 is used to place EP tubes or sample bottles filled with liquid, and the liquid contained in ...

Embodiment 2

[0058] A kind of adsorbent is polyvinyl alcohol modified expanded graphite, and the specific preparation method is as follows:

[0059] (1) Weigh natural flake graphite, add it into 1mol / L NaOH solution, react at 25°C, 60rpm for 2.5h, after the reaction is completed, filter out graphite, rinse with deionized water, and dry at 100°C;

[0060] (2) After adding potassium permanganate to the dried graphite and mixing, slowly add concentrated sulfuric acid and concentrated nitric acid, stir and mix, and react for 40 minutes at 25°C; the graphite, concentrated sulfuric acid, concentrated nitric acid and permanganic acid The mass ratio of potassium is: 1:2:0.5:0.1;

[0061] (3) Slowly add concentrated sulfuric acid and concentrated nitric acid to the above reaction system in a mass ratio of 1:1, stir and mix, and react for 40 minutes at 25°C;

[0062] (4) After the reaction was completed, the graphite was filtered out, washed 3 times with dehydrated alcohol, each 5min, to obtain exp...

Embodiment 3

[0076] The polyvinyl alcohol prepared in Example 2 is based on the number of electric pipettes 7 being 6×1, the carrying holes 9-1 on the disc changer 9 having 6 rows, 6 holes in each row, and the adsorbent in the extraction tip 8 Modified expanded graphite was used as an example to perform solid-phase extraction on polycyclic aromatic hydrocarbon samples in seawater. The electric pipette 7 is a 5mL electric pipette; the extraction tip is 5mL.

[0077]The 6 rows of carrying holes are placed in order: EP tubes for activation solution, EP tubes for samples to be tested, EP tubes for cleaning solution, EP tubes for eluent, EP tubes for waste solution, and sample bottles.

[0078] The concentrations of 16 PAHs in the spiked seawater are all 0.5ppm

[0079] Set up Controller 2 to implement the following process:

[0080] (1) Driven by the first motor 11, the EP tube of the adorned activating liquid on the disc changer 9 moves to the electric liquid aspirator 7, and the electric l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com