Method for preventing sample impact in determination of crude oil

A crude oil and sample flushing technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as the accuracy of crude water content determination and sample flushing that affect the integrity of samples, and achieve the effect of protecting integrity and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

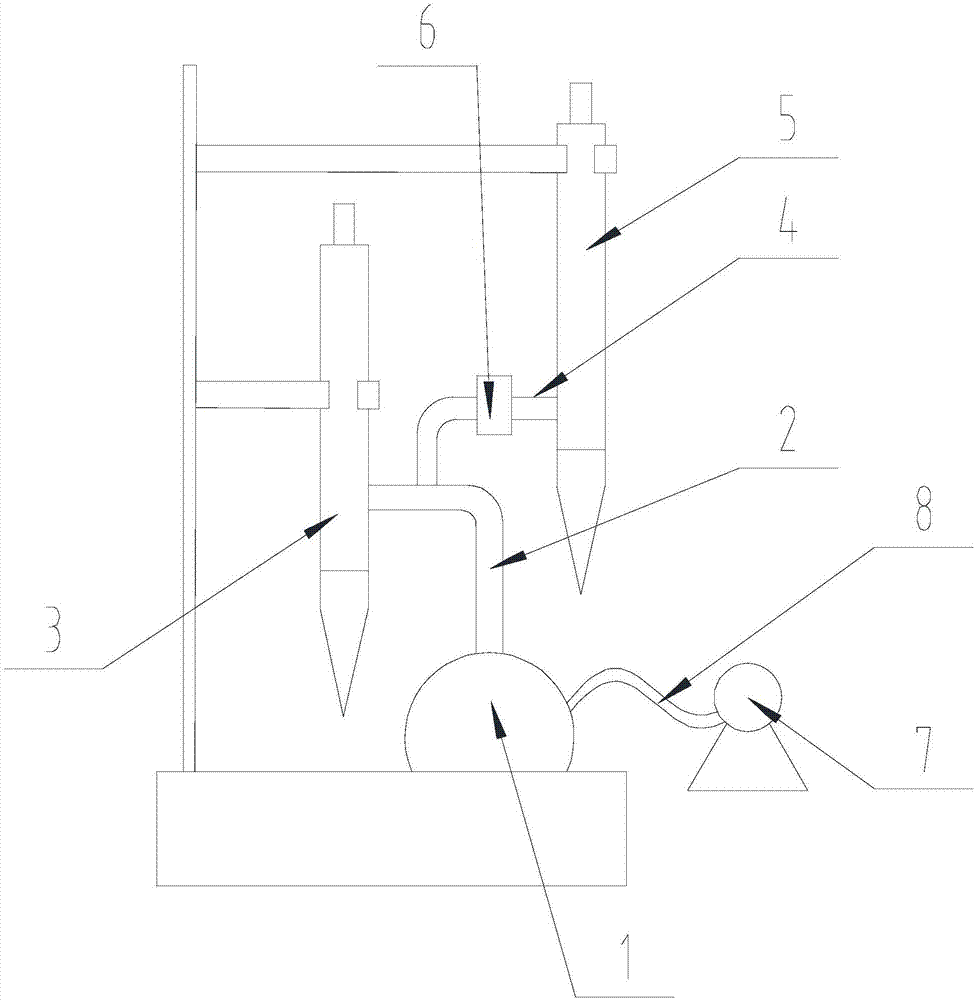

[0031] Such as figure 1 As shown, the present invention prevents the sample flushing method of crude oil measurement, comprising the following steps: Step A: connecting the heating bottle 1, the exhaust pipe 2 and the condenser 3 in the crude oil water content measuring instrument in sequence, and the heating bottle 1 Contains sample crude oil;

[0032] Step B: Connect the condensation pipe 5 to the exhaust pipe 2 through the connecting pipe 4, install the solenoid valve 6 on the connecting pipe 4, and control the opening and closing of the connecting pipe 4 through the solenoid valve 6;

[0033] Step C: installing the liquid level sensor in the inner tube of the condenser 3;

[0034] Step D: Connect the solenoid valve 6 and the liquid level sensor to the controller. The liquid level sensor transmits the liquid level information in the inner tube of the condenser 3 to the controller, and the pressure sensor transmits the pressure information in the inner tube of the condenser...

Embodiment 2

[0038] The present invention is based on embodiment 1, and the present invention is further described.

[0039] Such as figure 1 As shown, the method of the present invention to prevent sample flushing during crude oil determination also includes step E arranged after step D, said step E: the pressure sensor is arranged on the top of the inner tube of the condenser 3, and the pressure sensor is connected with the control The pressure sensor transmits the pressure information in the inner pipe of the condenser 3 to the controller, and the controller receives the information from the pressure sensor, and controls the on-off state of the solenoid valve 6 according to the pressure information.

[0040] When the condensation speed of the condenser 3 is slow, and there is a lot of gas in the inner tube and the pressure is high, the oil and gas will rush out of the condenser 3, which is not conducive to protecting the integrity of the sample. Therefore, a pressure sensor is set on t...

Embodiment 3

[0042] The present invention is based on embodiment 2, and the present invention is further described.

[0043] Such as figure 1 As shown, the method of the present invention to prevent sample flushing during crude oil determination also includes step F arranged before step A and step G arranged after step E;

[0044]The step F: put the heating bottle 1 containing the crude oil into the cooling device, perform cooling treatment on it, and then send the heating bottle 1 that has completed the cooling treatment into step A;

[0045] Step G: start the vacuum pump 7, and make the vacuum pump 7 pump out the gas in the heating bottle 1 through the exhaust pipe 8, so that the heating bottle 1 is under negative pressure.

[0046] Before distillation, earlier with vacuum pump 7, the air in heating bottle 1 is taken away a part, makes the air pressure in vacuum pump 7 less than one MPa. Reducing the air pressure in the heating bottle 1 can correspondingly reduce the temperature requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com