Unidirectional fiber composite material random structure generation method and system

A technology of composite materials and unidirectional fibers, applied in the field of materials, can solve problems such as characterization and reconstruction of random distribution of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

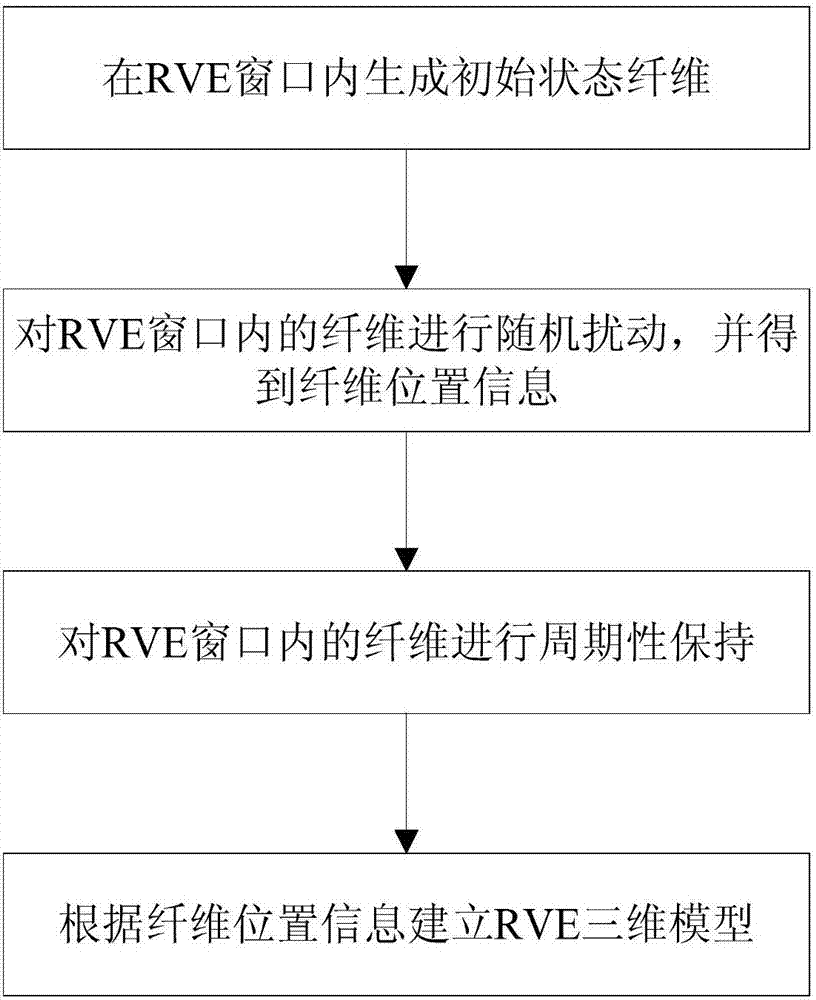

[0029] Such as figure 1 As shown, the method for generating a unidirectional fiber material model in this embodiment includes the following steps:

[0030] 1) Generate initial state fibers within the RVE window.

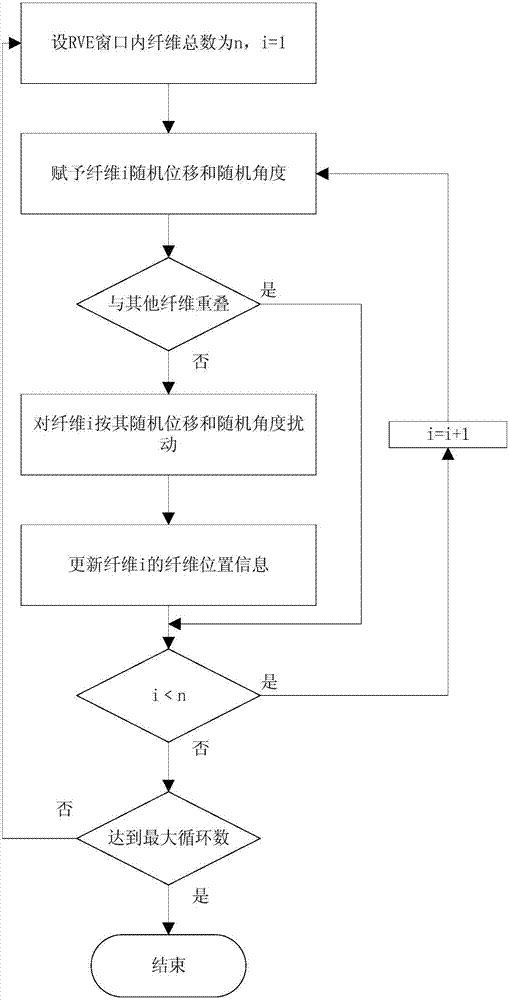

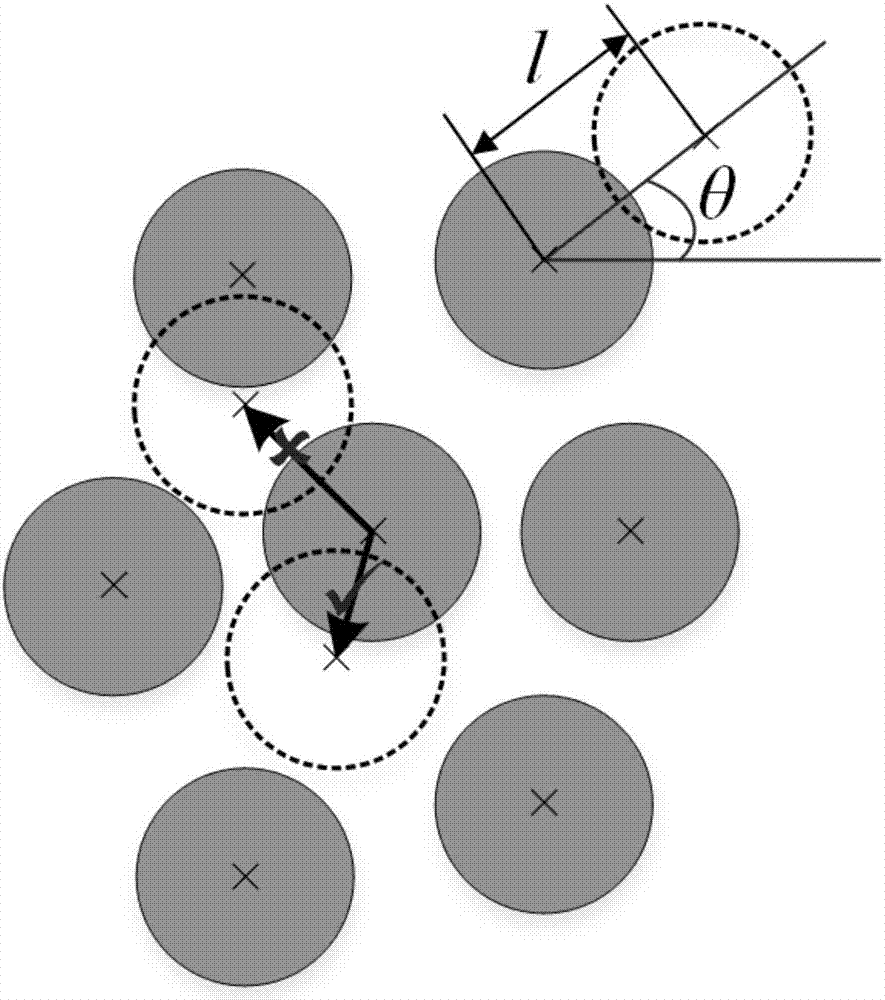

[0031] 1.1) Determine the fiber parameters in the initial state. Fiber parameters include fiber radius r, target volume fraction V f , the minimum distance l between fiber boundaries min And the side length s of the square RVE window, where: s=50 μm, r=3.115 μm, l min = 0.2μm, V f = 65%.

[0032] 1.2) Generate fully densely packed fibers within the RVE window. In the square area of the RVE window, a point is used as the center of the circle, and the radius is given to represent the circle of the fiber section. Since the RVE is assumed to be a straight line along the fiber direction, the volume fraction of the fiber is equal to the area fraction of all circles in the section. Put as many fibers as possible in the window that are completely densely arranged, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com