340-GHz thin-film type transmission polarized converter

A polarization conversion and thin-film technology, which is applied in the field of radar and communication, can solve the problems of poor performance of polarization converter devices, unsatisfactory phase modulation characteristics, and large transmission loss of polarization converters, so as to avoid the loss of substrate materials. Selection problem, avoiding the processing accuracy problem of simple metal grid, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

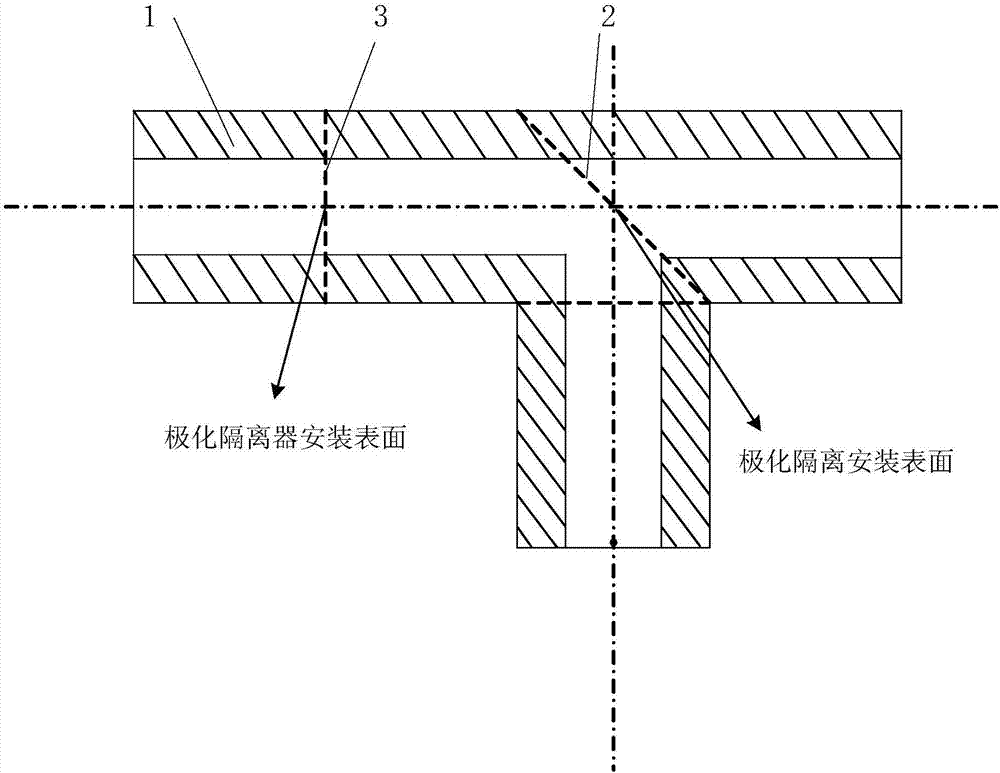

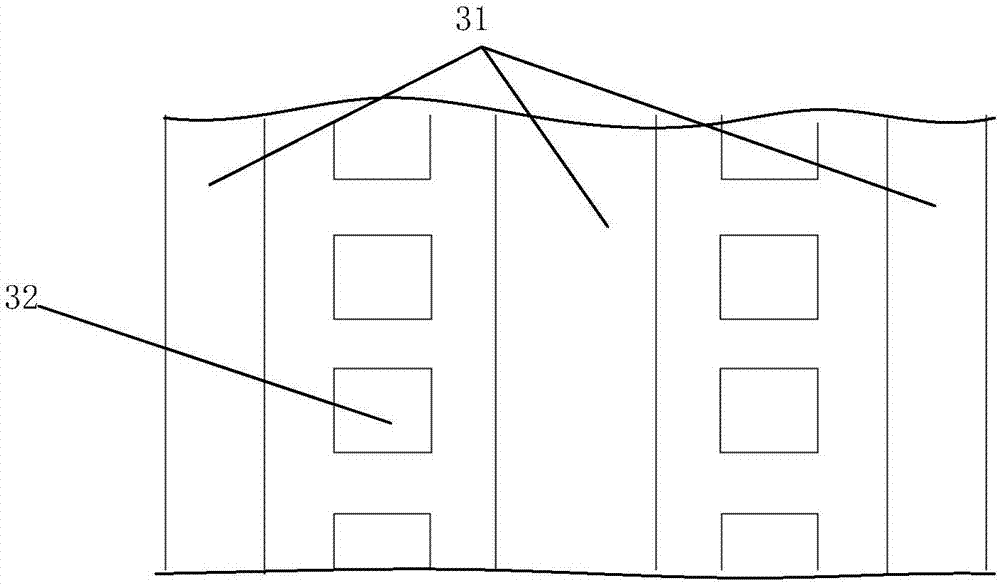

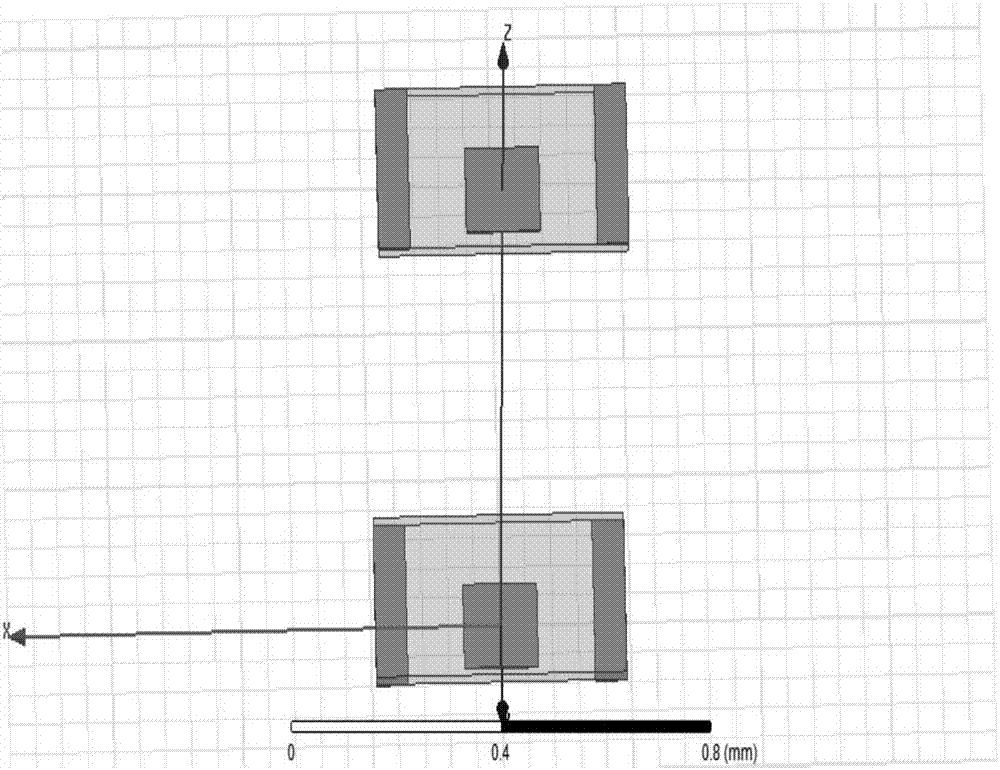

[0023] The present invention provides a 340GHz film-type transmissive polarization converter, which is placed inside a 340GHz thin-film device-based broadband duplexer that absorbs the cavity, wherein the duplexer includes: a wave-absorbing cavity 1, a pole A polarization isolator 2 and a polarization converter 3; the absorbing cavity 1 is a cylindrical cavity with a T-shaped external shape, which is a hollow cavity 1 whose internal shape is consistent with the external shape and runs through each end surface , the polarization isolator 2 is an elliptical metal gasket, and one side of the metal elliptical gasket is provided with a film with a metal wire grating, and the device is placed above the vertical hollow cavity on the suction The intersection of the horizontal and vertical hollow cavities of the wave cavity body 1 is 45 degrees clockwise with the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com