Glass fiber lubricating oil preparing system

A technology of lubricating oil material and configuration system, which is applied to lubricating compositions, mixer accessories, mixers with rotary stirring devices, etc. The effect of increasing the loss and improving the accuracy of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

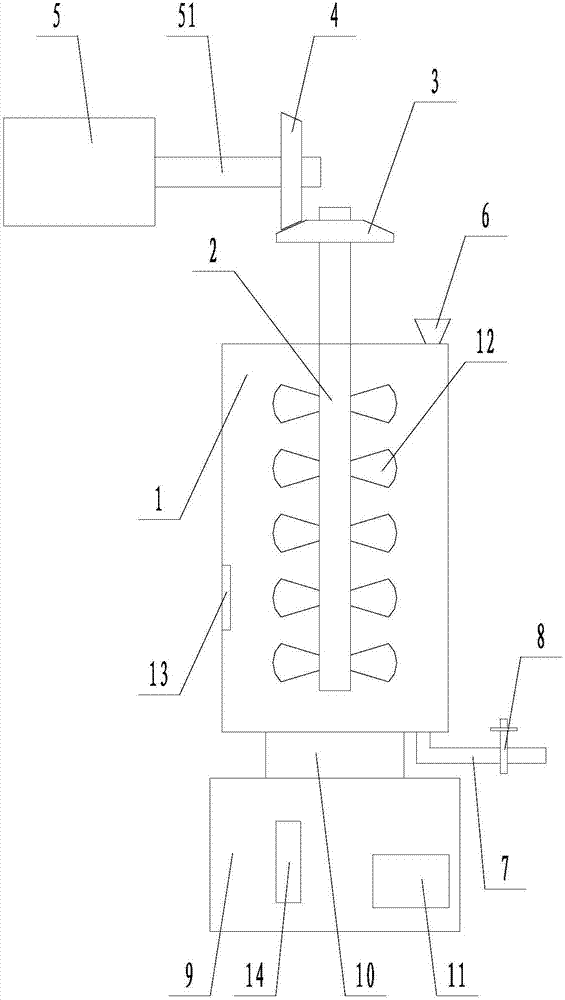

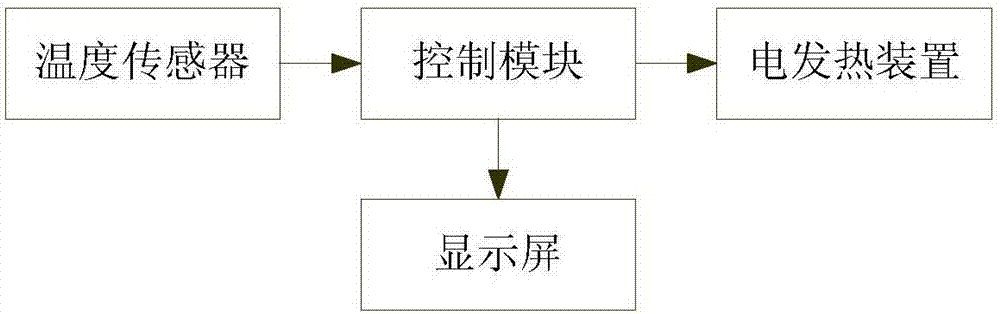

[0023] like figure 1 and figure 2 A glass fiber lubricating oil material configuration system as shown includes a container 1, a stirring rod 2, a base 9, an electric heating device 10 is arranged on the upper surface of the base 9, and the container 1 is placed on the electric heating device 10; the stirring rod 2 One end is located in the container 1 and the other end is located outside the container 1. The end of the stirring rod 2 located outside the container 1 is fixedly sleeved with a first bevel gear 3; it also includes a second bevel gear 4 and a motor 5. The second bevel gear 4 Meshing with the first bevel gear 3, the second bevel gear 4 is fixedly sleeved on the output shaft 51 of the motor 5, and the output shaft 51 and the stirring rod 2 are perpendicular to each other; Part of the fan blade 12 is fixedly connected; it also includes a temperature sensor 13, a control module 14, and a display screen 11. The temperature sensor 13 is arranged on the inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com