Punching technology of silicon steel sheet

A silicon steel sheet and process technology, applied in the field of stamping process of silicon steel sheet, can solve the problems of easy deformation or burr, uneven cooling rate, complicated processing process, etc., so as to reduce the risk of dislocation of assembly, and facilitate subsequent assembly and location. High precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

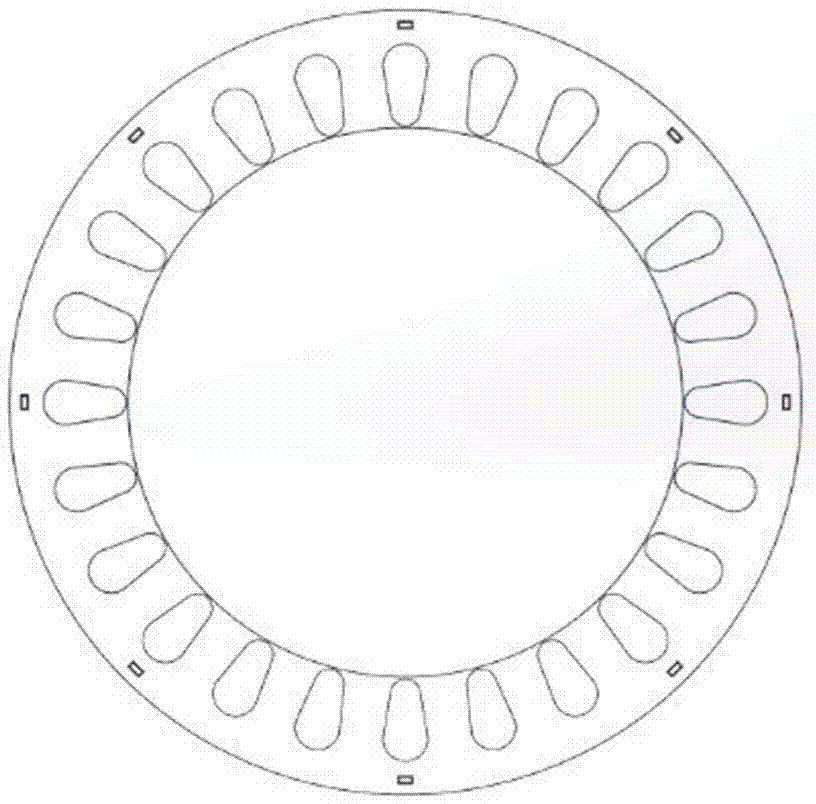

[0032] The invention discloses a stamping process of a silicon steel sheet, such as Figure 1 to Figure 2 shown, including the following steps:

[0033] 1) Before stamping, place the raw material sheet in the oven, fix the front end of the raw material sheet to the billet making station of the composite mold, turn on the oven to heat the raw material sheet, and heat the mold to control the heat preservation of the mold;

[0034] 2) Stamping the blank, the pressing tool compresses the blank, and the composite mold directly stamps the raw material sheet at one time through the blanking punch to obtain the silicon steel sheet blank;

[0035] 3) Punch the middle through hole, the composite punching machine moves the billet prepared in step 2) to the middle through hole stamping station, the pressing tool presses the billet, and the through hole punch punches the billet at one time to obtain the first half finished product;

[0036] 4) Stamping the enameled wire groove, the compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com