A method of manufacturing a wear-resistant impeller of a small sand suction pump

A manufacturing method and sand suction pump technology, which is applied in the field of impeller manufacturing, can solve problems affecting sand mining efficiency and cost, poor anti-sand wear performance, large casting shrinkage resistance, etc., to reduce maintenance costs and improve durability. Abrasive, easy-to-machining effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to fully understand the technical solutions and beneficial effects of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples.

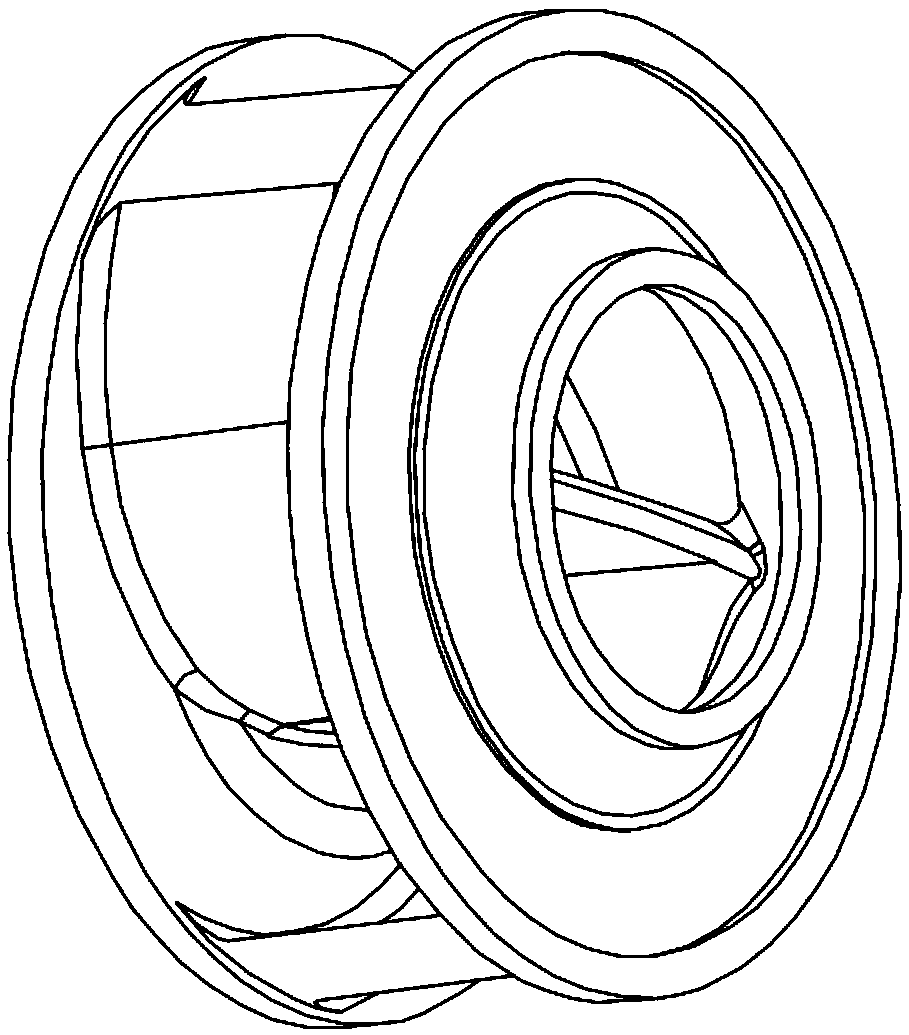

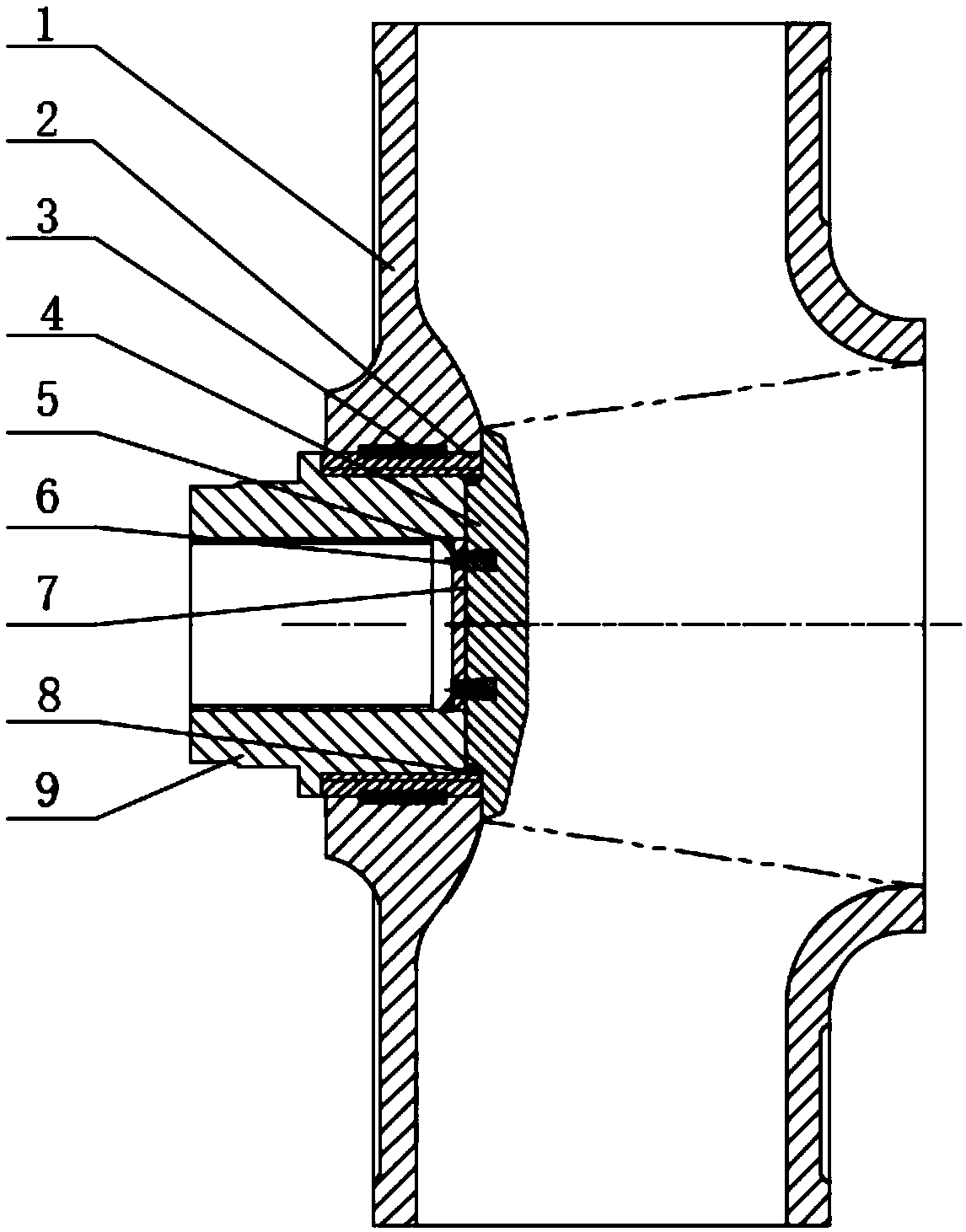

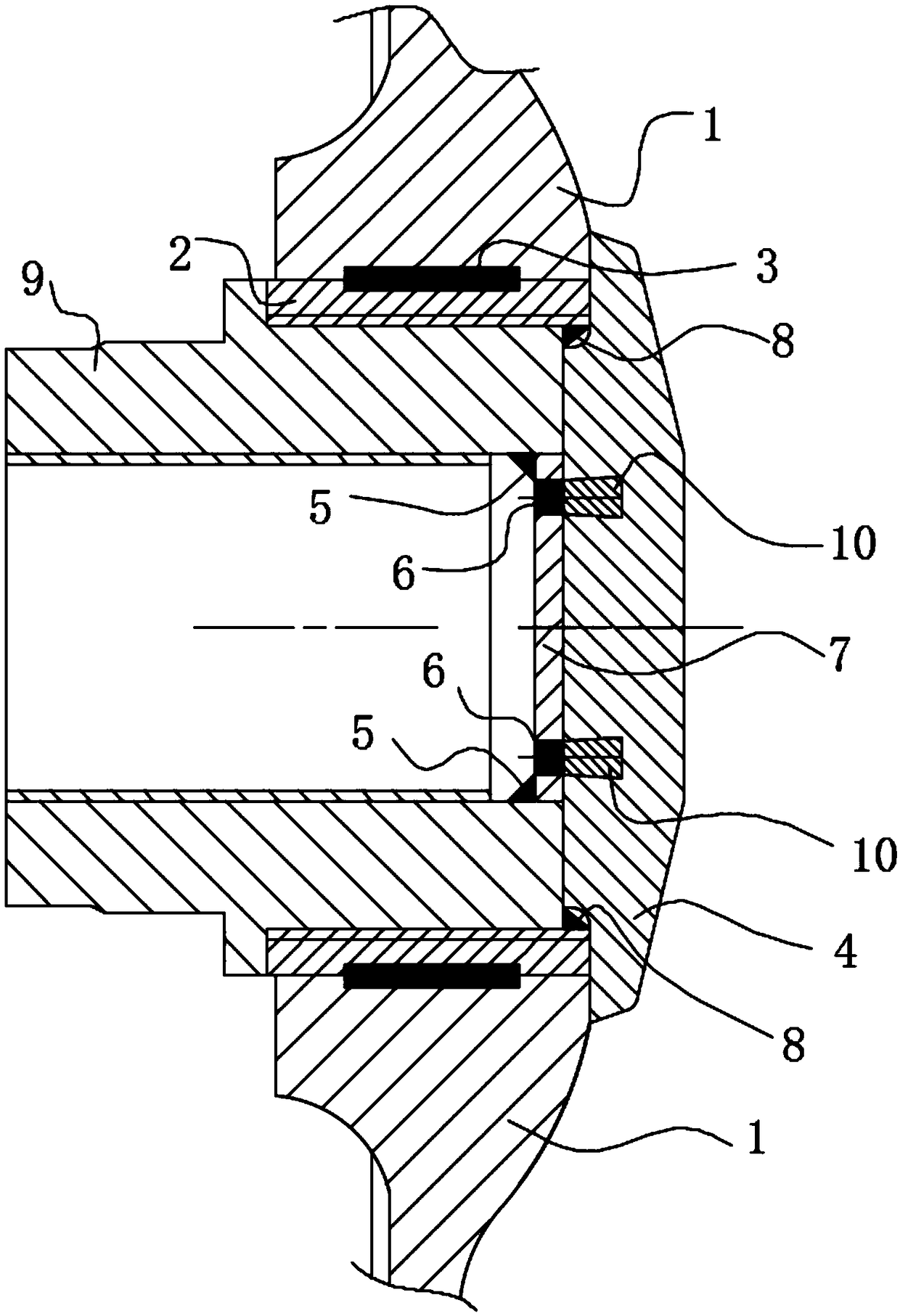

[0037] Such as Figure 1 to Figure 3 As shown, a wear-resistant impeller of a small sand suction pump has an impeller main body 1 and a wheel core 9. An impeller embedded ring 2 is provided at the connection between the impeller main body 1 and the wheel core 9, and the outer surface of the impeller embedded ring 2 is There is a surfacing weld 3 along the axial direction, the impeller pre-embedded ring 2 is cast together with the impeller main body 1 in a pre-embedded manner, the outer surface of the wheel core 9 is provided with threads, and the impeller pre-embedded ring 2 and the wheel core 9 are matched by threads Rotating, the threaded end of the wheel core 9 and the inner surface of the impe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com