Lifting cantilever supporting device

A support device and cantilever technology, applied in the field of liftable cantilever support devices, can solve the problems of high assembly cost, low assembly efficiency, waste of manpower, etc., and achieve the effects of improving assembly efficiency, simple structure, and smart design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

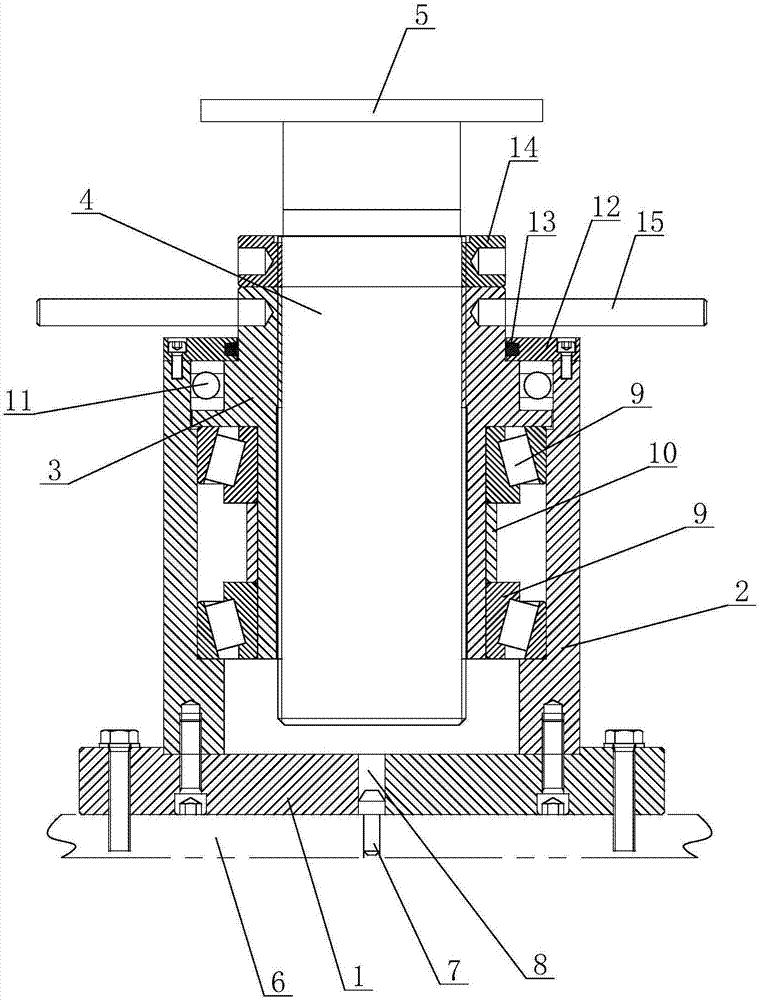

[0014] see figure 1 as shown, figure 1 It is a schematic structural diagram of the liftable cantilever support device provided in Embodiment 1 of the present invention. In this embodiment, a liftable cantilever support device includes a fixed plate 1, a support cylinder 2, an internal thread sleeve 3, a screw rod 4 and a support plate 5, and the bottom of the fixed plate 1 is fixed on the bottom plate 6 by fixing screws , and between the bottom plate 6 and the fixed plate 1, there are positioning pins 7 and positioning holes 8 that cooperate with each other. The support cylinder 2 and the fixed plate 1 adopt a split structure, which is fixed on the On the fixed plate 1.

[0015] The internal thread sleeve 3 is rotatably arranged in the support cylinder 2 through a bearing assembly, and the bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com