Thermoprinting plate and thermoprinting method of same-position different patterns

A technology for hot stamping plates and patterns, applied in the directions of copying/marking methods, printing, printing devices, etc., can solve the problems of non-reusability, high production cost, and high cost, achieve low production difficulty, improve versatility, hot stamping Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

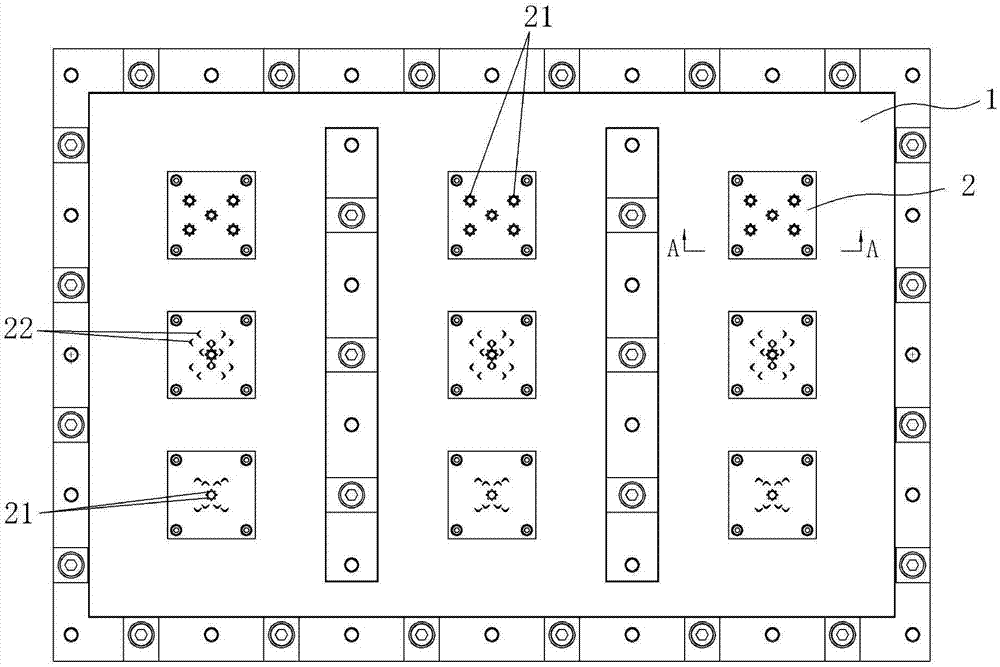

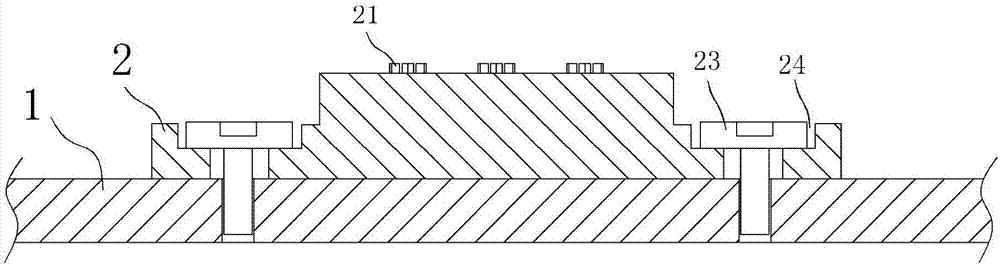

[0028] refer to figure 1 with figure 2 , the hot stamping plate with the metamorphic pattern includes a first liner 1 and a first hot stamping mold 2 . There are multiple first hot stamping molds 2, and each first hot stamping mold 2 is respectively installed on the first liner 1 through bolts 23. The first hot stamping mold 2 is also provided with a hole 24 that matches the bolt 23, and the hole 24 is connected with the bolt 23 A gap is left between the bolts 23 to facilitate the fine adjustment of the first hot stamping mold 2 during installation.

[0029] The hot stamping surface of each first hot stamping mold 2 can be provided with different protrusions 21 or grooves 22 at different positions according to needs, so that the protrusions 21 or grooves 22 can be formed on the substrate 5 after hot stamping different patterns.

[0030] On the other hand, each first hot stamping mold 2 can be provided with a plurality of protrusions 21 or grooves 22, and the width of each ...

Embodiment 2

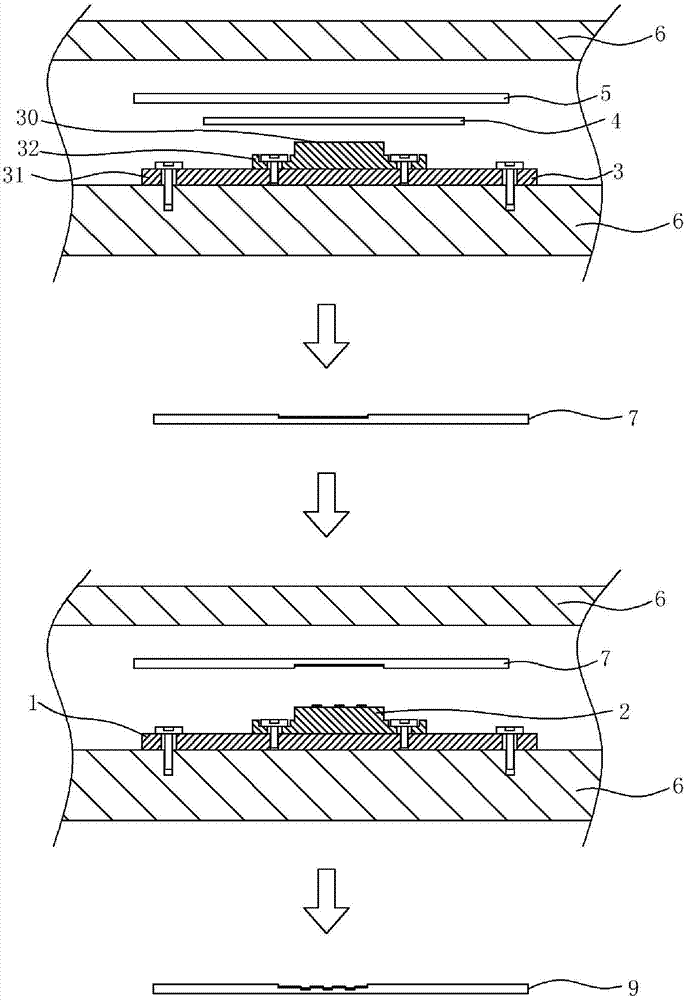

[0032] refer to figure 1 — image 3 , the hot stamping method of the same position and different image pattern hot stamping plate of the same position and different image pattern, in addition to the hot stamping plate of the same position and different image pattern, the following equipment is also required:

[0033] Flat hot stamping plate 3, the structure of flat hot stamping plate 3 is similar to that of common hot stamping plates in the market, and it includes a second liner 31 and a second hot stamping mold 32, and there are multiple second hot stamping molds 32, many A second hot stamping mold 32 is installed on the second liner 31 by bolts, and the hot stamping surface of the second hot stamping mold 32 is provided with a flat surface 30, which is not provided with any protrusions or grooves, and the plane shape It can be set according to the desired pattern, such as circle, oval, square, etc.

[0034] Hot stamping machine 6, hot stamping machine 6 can choose commerci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com