Semi-trailer airbag intermediately-arranged suspension device

A suspension device and semi-trailer technology, applied in the direction of suspension, elastic suspension, vehicle springs, etc., can solve problems such as tires in the air, broken steel plates, broken shafts, etc., to achieve increased balance performance, good shock absorption and noise reduction, and shock absorption. even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

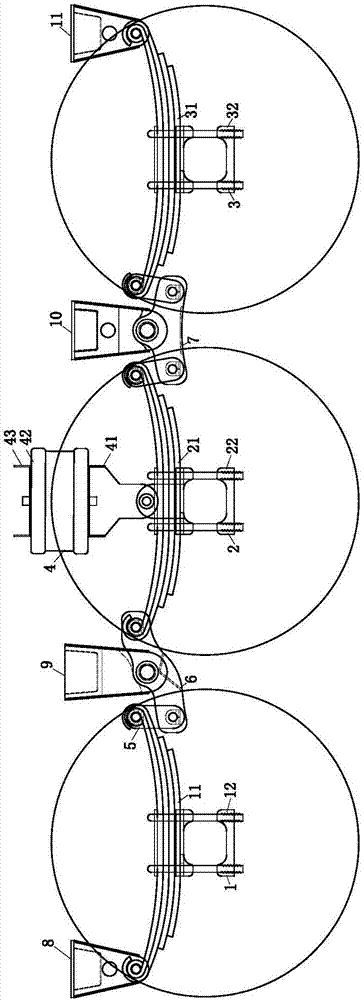

[0021] As an embodiment of the present invention, the jacking mechanism 4 includes a rotating lower supporting board 41, an air bag 42 and an upper top board 43; the rotating lower supporting board 41 is connected with the middle bridge 22, and the rotating lower supporting board 41 is used to support The airbag 42, and the rotating lower supporting plate 41 is provided with a through hole, the through hole is used to place the air inlet hole of the airbag 42; , so as to realize the lifting of the front axle mechanism 1 and the rear axle mechanism 3; the upper top plate 43 is connected to the upper surface of the air bag 42, the upper top plate 43 is fixedly connected with the body, and the upper top plate 43 is provided with a through hole, which is used to place The air outlet hole of the airbag 42; when working, the air supply system of the main vehicle feeds gas into the air inlet hole of the airbag 42, and the air pressure generated by the gas makes the airbag 42 bulge, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com