Mounting method for side pushing device

An installation method and side thruster technology, applied in the field of ships, can solve the problems of affecting welding quality, low operation efficiency, narrow space, etc., and achieve the effects of improving welding quality and efficiency, and facilitating adjustment and welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

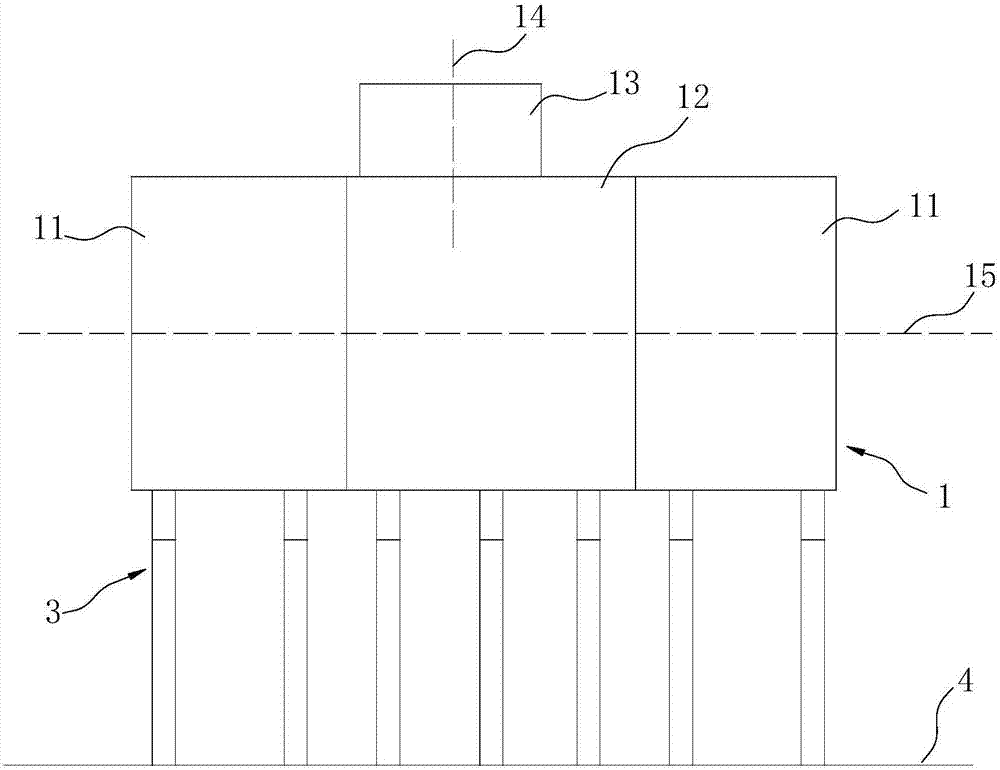

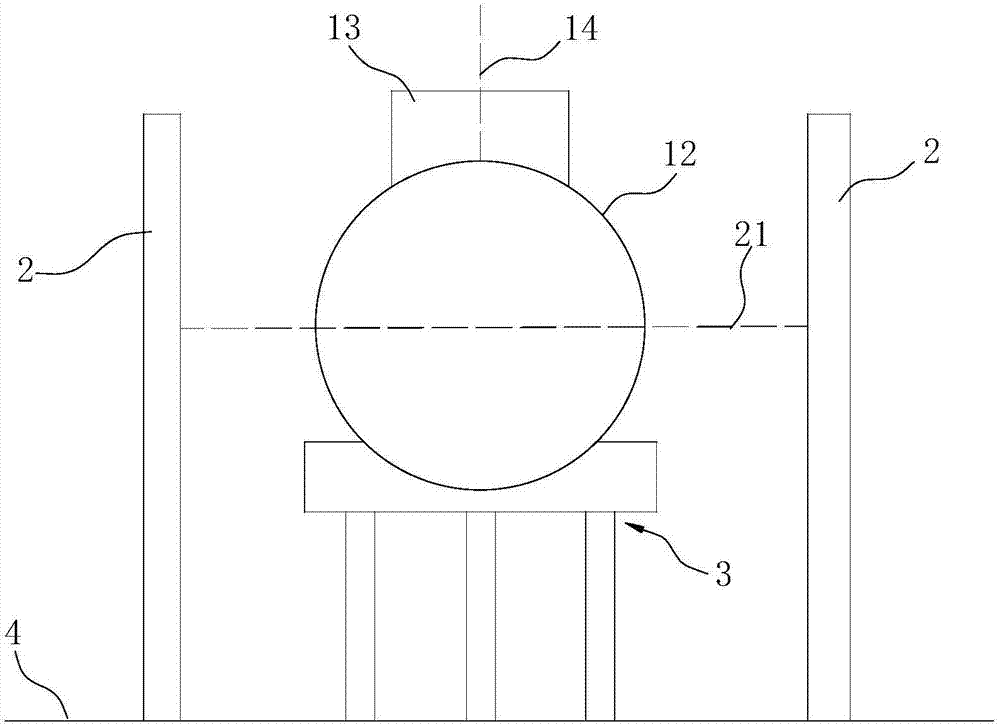

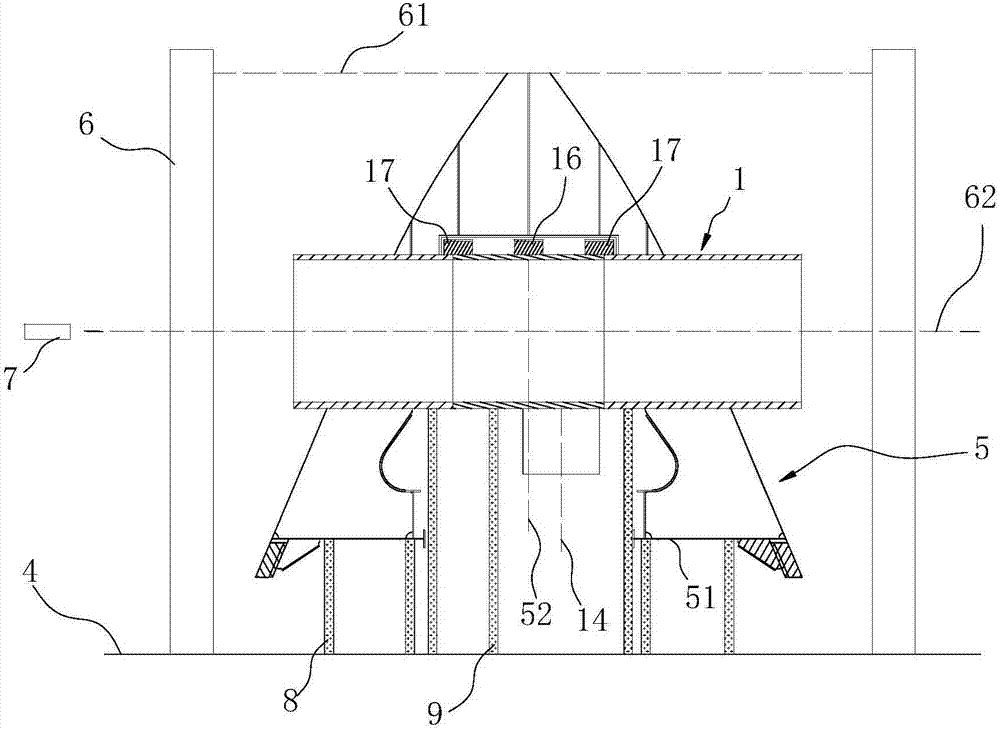

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0036] Such as Figure 1~3 As shown, in this embodiment, a side thruster installation method according to the present invention provides a side thruster 1, comprising a side thruster cylinder 12 and two side thrusters respectively arranged on the side thruster cylinder 12. The connecting cylinder 11 at the end comprises the following steps:

[0037] Step S10, assembling and welding the two connecting cylinders 11 and the side thruster cylinder 12 into the side thruster 1 while assembling the section tire frame 8 on the section 5;

[0038] Step S20 , hoisting the lateral thruster 1 onto the segment tire frame 8 and welding it with the segment 5 .

[0039] After welding the two connecting cylinders 11 and the side thruster cylinder 12 into the side thruster 1, the side thruster 1 and the section 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com