Brine treatment process for preparing industrial salt

A technology for industrial salt and treatment process, applied in water/sewage treatment, biological water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as occupancy, large footprint, and increased treatment process complexity. Achieve the effect of simple and efficient treatment and improved clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

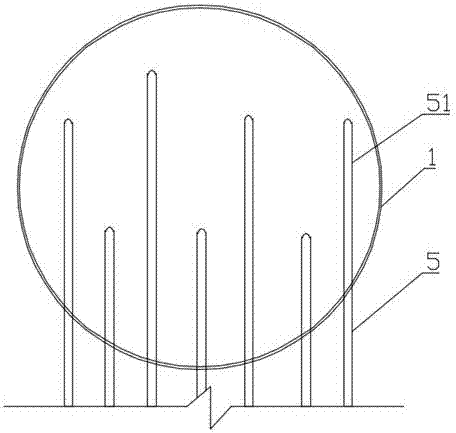

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings. Wherein, the descriptive terms such as up, down, left, right, etc. are used for the description, with the purpose of helping readers to understand, but not intended to limit.

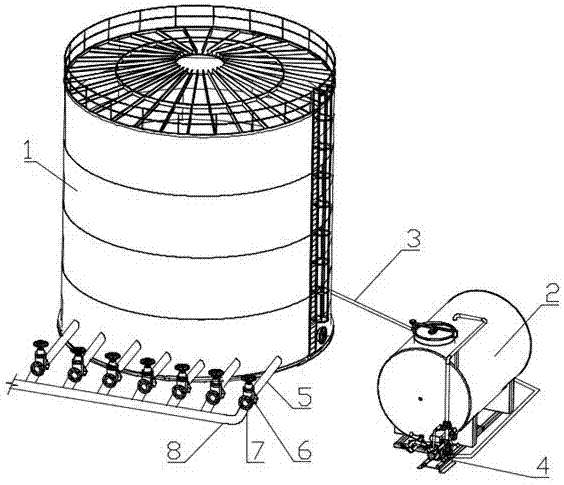

[0041] During specific implementation: if Figure 1 to Figure 2 As shown, the brine treatment process for preparing industrial salt includes the steps of storing brine and adding alkali to brine; wherein, the step of storing brine is to use brine storage tank 1 to store brine; the adding of brine to brine The alkali added in the alkali step is lye, and the lye is stored in a lye storage tank 2, and the lye storage tank 2 communicates with the brine storage tank 1 through a lye delivery pipe 3, and the A metering pump 4 is sealed and fixedly installed on the lye delivery pipe 3 .

[0042] During implementation, the metering pump 4 is preferably a diaphragm metering pump 4 with a "return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com