Kitchen cleaning wastewater treatment device

A technology for cleaning waste water and a processor, which is applied in the field of kitchen tableware cleaning sewage treatment, can solve the problems of waste oil resource waste, oil pollution environment, etc., and achieve the effects of pollution reduction, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

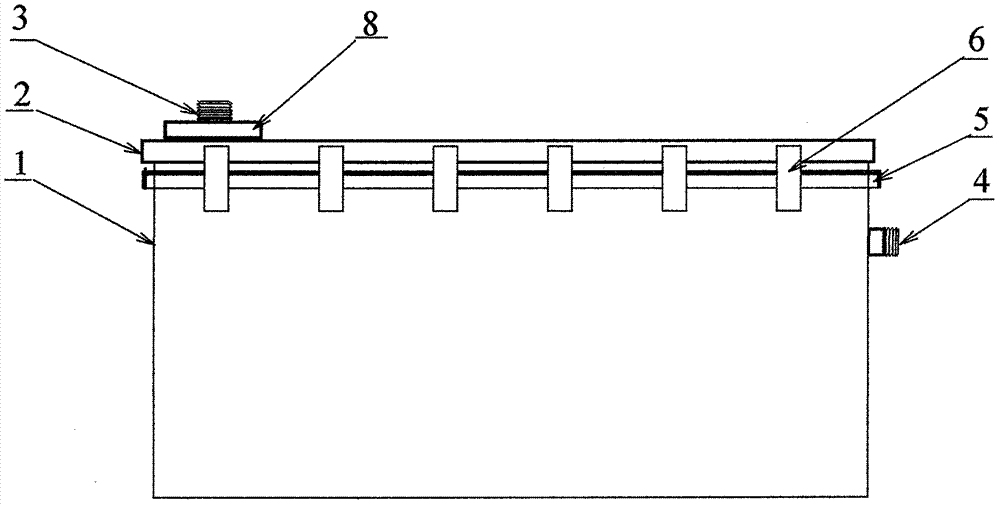

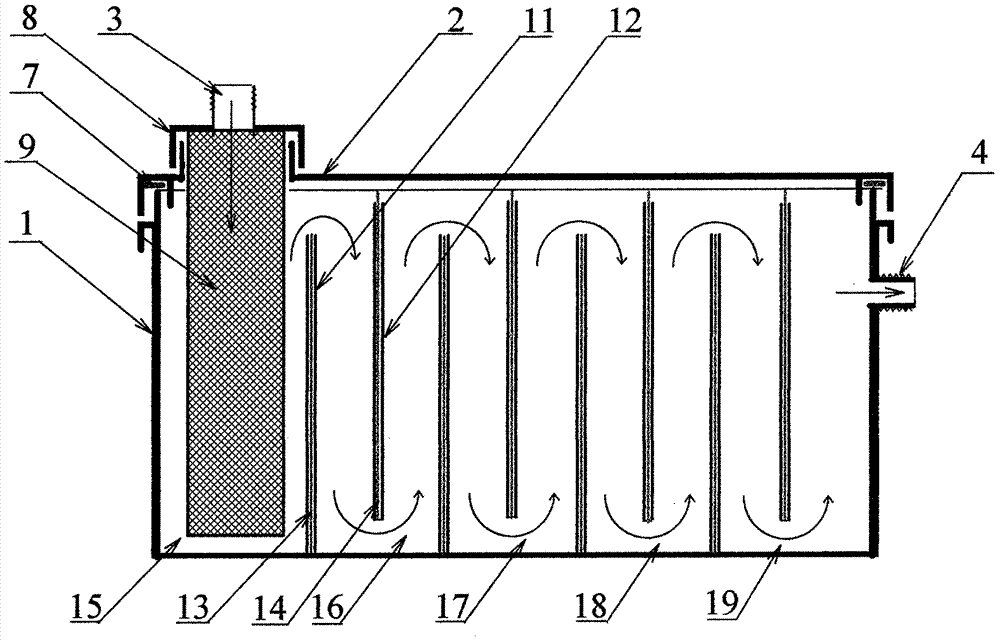

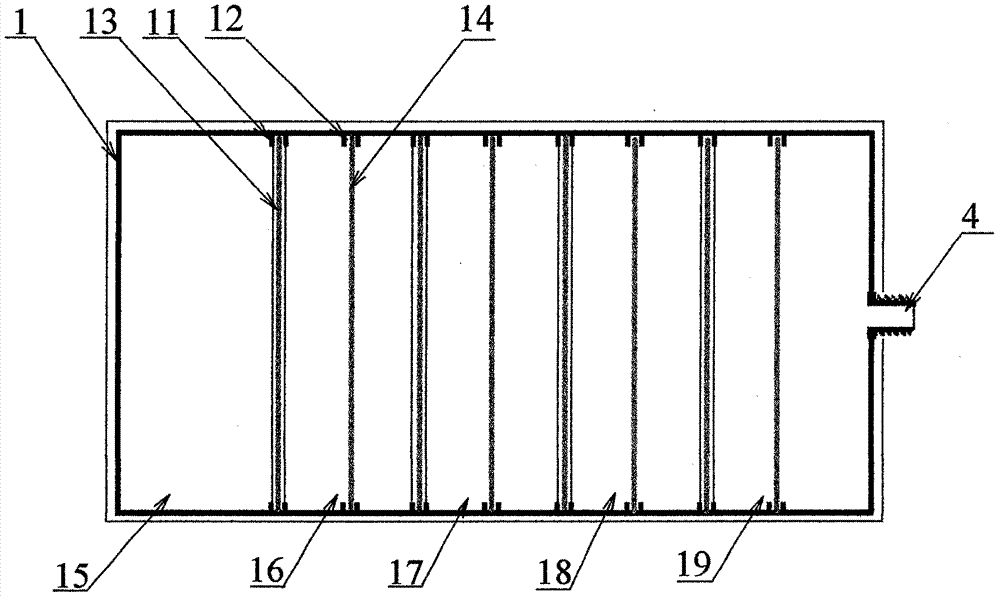

[0012] This patent includes in the accompanying drawings, by casing (1), loam cake (2), filter screen fixing cover (8), filter screen (9), lower baffle plate (13), upper baffle plate (14) are connected together Composition, in which the shell (1) and the upper cover (2), there is a case cover silicone pad (7) between them, which are clamped and sealed together by the buckle (6), and the inside of the shell (1) is in the lower baffle slot (11) Above, it is installed and inserted into the lower baffle (13), forming the first settling chamber (15), the second settling chamber (16), the third settling chamber (17), the fourth settling chamber (18), the fifth settling chamber ( 19), the upper baffle plate slot (12) is installed and inserted into the upper baffle plate (14) to form a five-stage turn-back water flow channel, so that the water flow velocity becomes slower and the dregs in the water are deposited step by step, and the lower baffle plate (13) , The surface of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com