A microwave heating raking machine and its microwave heating wall

A technology of microwave heating and raking machine, which is applied in roads, constructions, road repairs, etc. It can solve the problems of ineffective bonding, excessive temperature difference, weak joints, etc., achieve good shielding effect, uniform heat dissipation, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

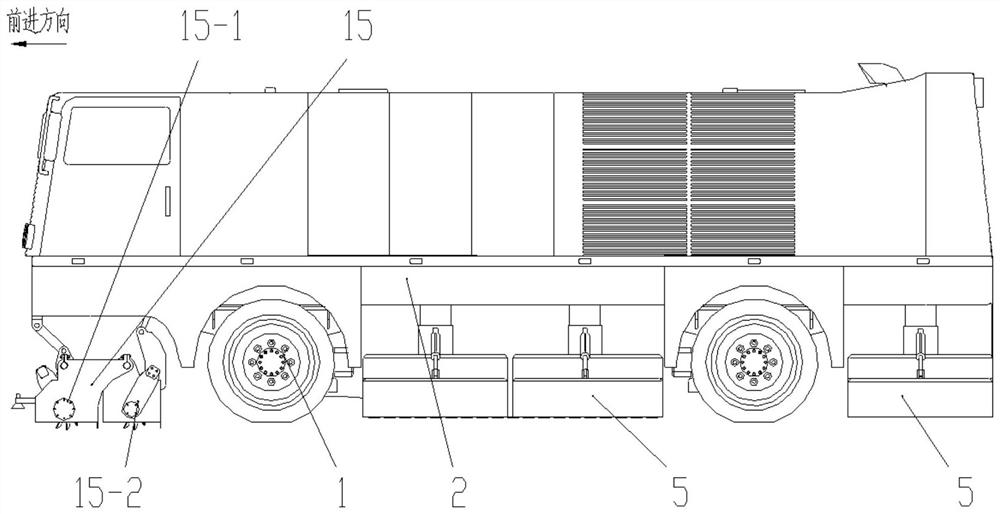

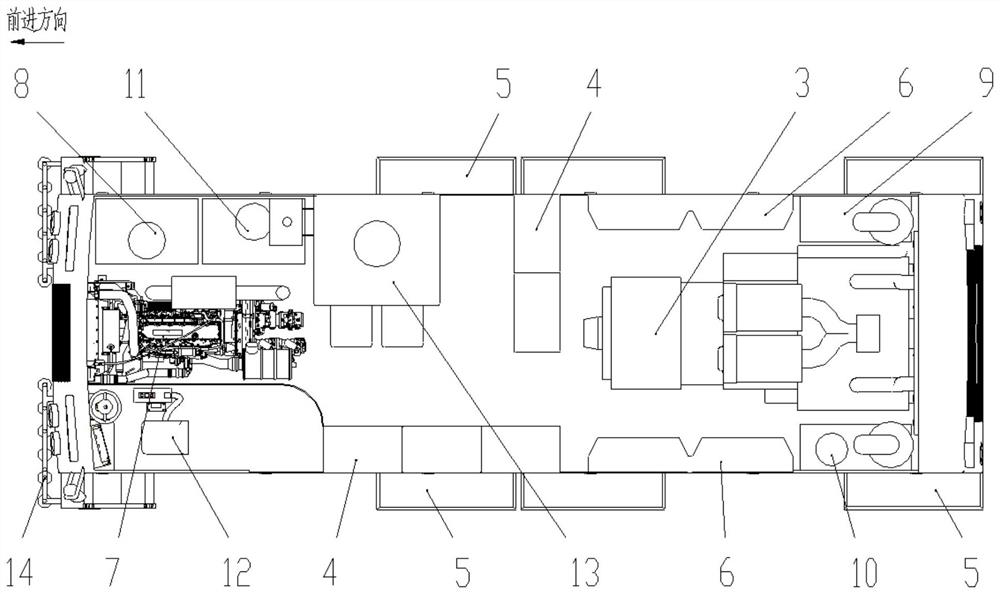

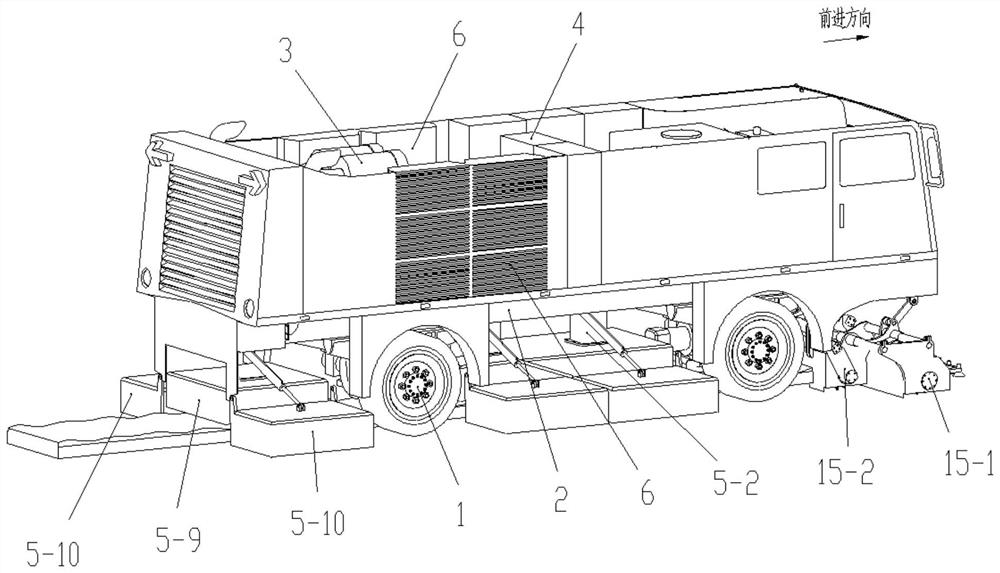

[0040] like figure 1 and Figure 5 As shown in the figure, a microwave heating rake of the present invention includes a chassis walking system 1, a frame 2, a generator set 3, a transformer box 4, a microwave heating wall 5, a cooling system 6, an auxiliary engine 7, a hydraulic system 8, an electrical System 9, fuel tank 10, water tank 11, cab 12, regenerant tank 13, regenerant spraying device 14 and raking device 15; the front and rear axles of the chassis walking system 1 are driven axles, and the upper part supports the frame 2 , and has the functions of continuously variable speed change and all-wheel steering, the generator set 3 is located at the rear of the frame 2, the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com