Fractured rock mass subgrade quadrangle anchoring anti-uplift pressing shifting foundation and construction method thereof

A technology of cracked rock mass and four corners, which is applied to the four corners of the cracked rock mass foundation to anchor the anti-uplift and pressure-shift foundation and its construction field, which can solve the problems of aggravated environmental damage, unsatisfactory reinforcement effect, and increased spoils, etc., to improve physical and mechanical properties , Improve the effect of physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

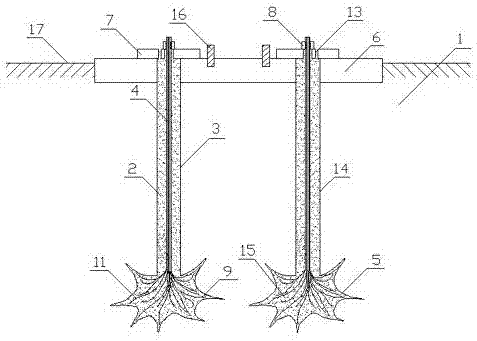

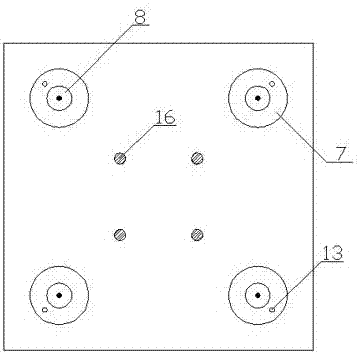

[0034] Such as Figure 1~3 As shown, the four corners of the cracked rock mass foundation are anchored against uplift and pressure displacement. It includes an upper plate 6 embedded in the cracked rock mass 1 and the upper surface is higher than the ground 17, four hairpin bolt bodies 4 and four backing plates 7 and Four anchor plates8.

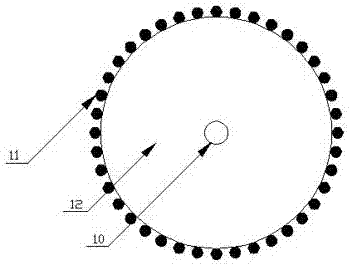

[0035] The upper plate 6 is a quadrilateral, with an anchor hole I arranged at each of its four corners; each backing plate 7 is provided with an anchor hole II; the bottom ends of the four anchor rod bodies 4 are anchored, and the top ends are respectively pierced. Go through an anchor hole I of the upper plate 6, and pass through an anchor hole II of a backing plate 7 to connect with an anchor plate 8; It is composed of steel wire or (and) other wires that can undergo large deformation. The lower part of the tensile filament 11 is bundled with the water-resistant explosive 12 equipped with the detonator 10 , and the tensile filament 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com