Road safe operation construction barrier structure and construction method thereof

A technology for safe operation and barrier, applied in building construction, fences, noise absorption devices, etc., can solve the problems of slow construction and dismantling, high risk of construction personnel, and a lot of manpower for fences, reducing manual operations. , saving labor cost, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

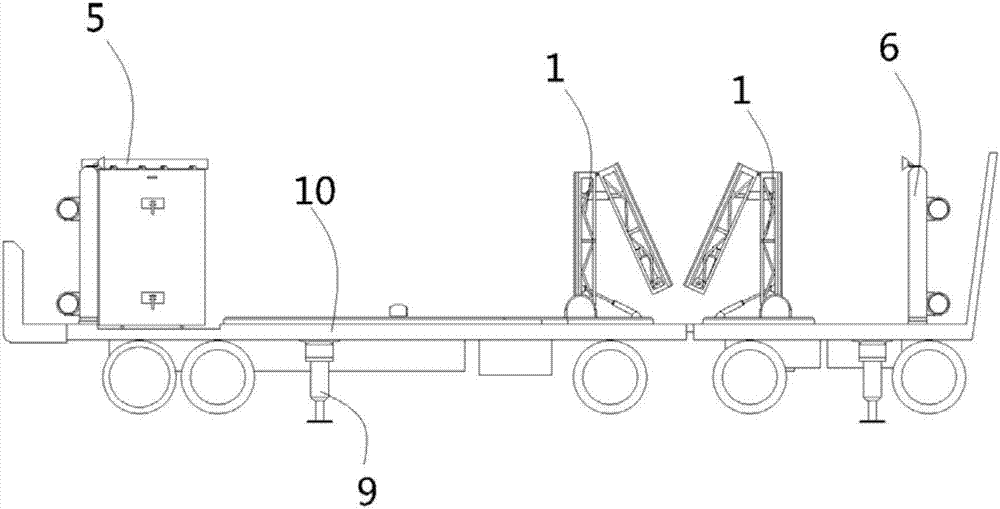

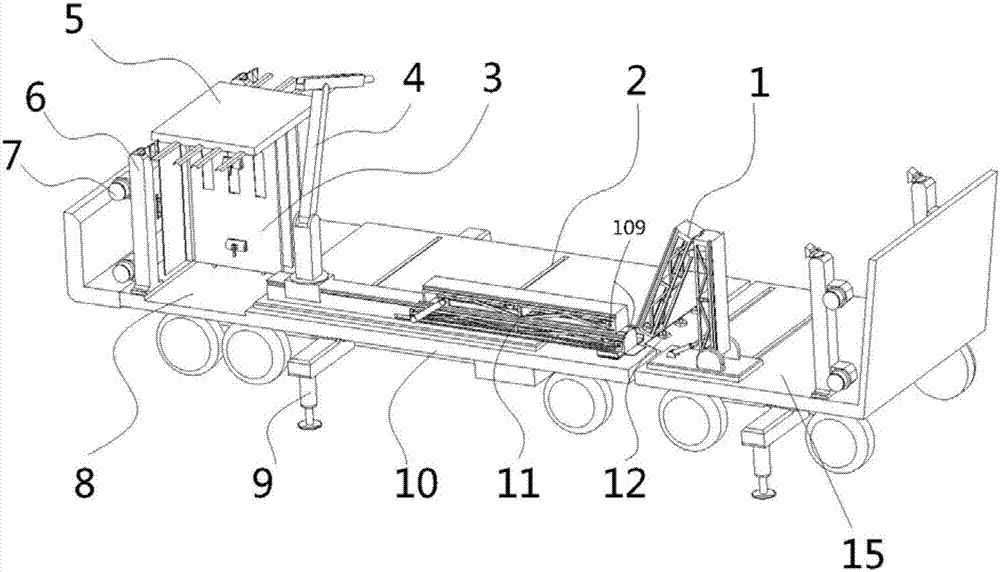

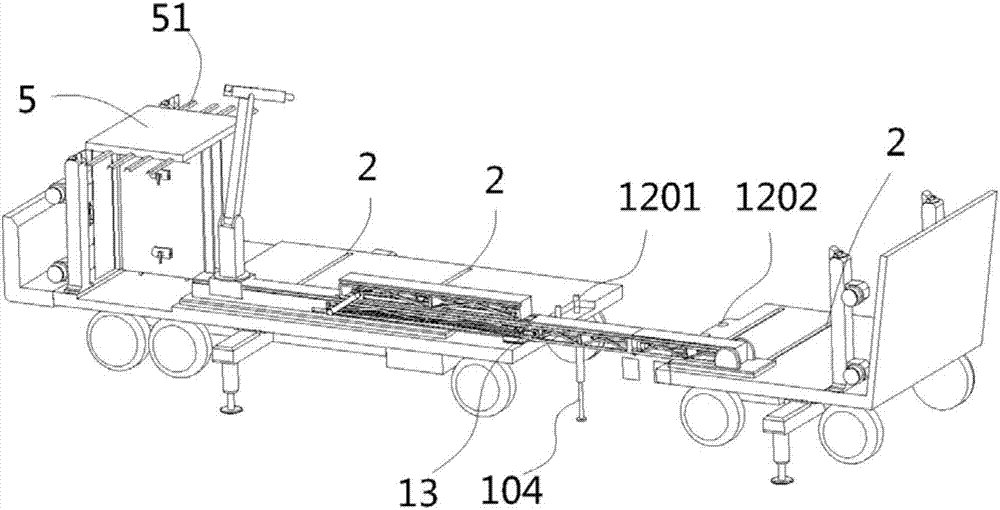

[0037] As shown in the figure, the construction barrier structure for road safety operations includes a traction platform 10, with hydraulic outriggers 9 installed below the traction platform 10. The traction platform 10 is divided into a front car body 8 and a rear car body 15. Fixed piles 6 are installed on the four corners of the traction platform 10, and winches 7 are installed on the fixed piles 6, wherein each fixed pile 6 is equipped with two winches 7 and the winches on each fixed pile 6 7 The level is the same, and the two fixed piles 6 on the same side are connected with the wire rope 14 between the winches 7 of the same level.

[0038] A top plate 5 is installed on the traction platform 10, and rail strips 51 are installed uniformly on the top plate 5, and the noise barrier 3 is embedded in the rail strip 51 by a guide cam 301 and uniformly hoisted under the top plate 5; on both sides of the noise barrier 3 A steel cord insert 304 is symmetrically provided, and a pulle...

Embodiment 2

[0050] As shown in the figure, the construction barrier structure for road safety operations includes a traction platform 10, with hydraulic outriggers 9 installed below the traction platform 10. The traction platform 10 is divided into a front car body 8 and a rear car body 15. Fixed piles 6 are installed on the four corners of the traction platform 10, and winches 7 are installed on the fixed piles 6, wherein each fixed pile 6 is equipped with two winches 7 and the winches on each fixed pile 6 7 The level is the same, and the two fixed piles 6 on the same side are connected with the wire rope 14 between the winches 7 of the same level.

[0051] A top plate 5 is installed on the traction platform 10, and rail strips 51 are installed uniformly on the top plate 5, and the noise barrier 3 is embedded in the rail strip 51 by a guide cam 301 and uniformly hoisted under the top plate 5; on both sides of the noise barrier 3 A steel cord insert 304 is symmetrically provided, and a pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com