Cylinder head of high-pressure common-rail diesel engine

A high-pressure common rail and cylinder head technology, which is applied to cylinder heads, cylinders, mechanical equipment, etc., can solve problems such as combustion deterioration, uneven spiral air flow, and poor power performance of diesel engines, so as to prevent the mixing rate of oil and gas and weaken the air The effect of exercise intensity and reduction of intake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with accompanying drawing and specific embodiment:

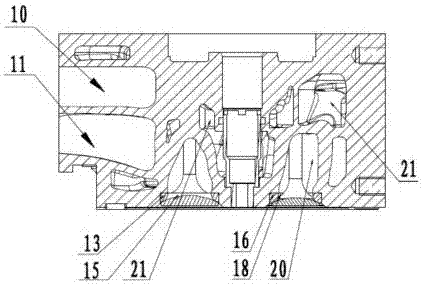

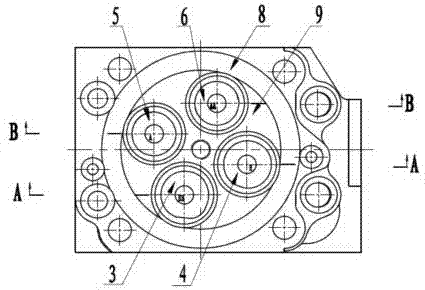

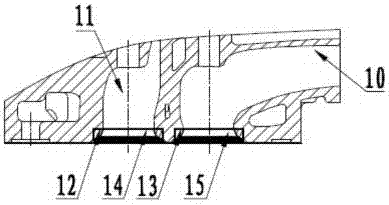

[0021] Such as figure 1 , figure 2 shown, and refer to image 3 , Figure 4 , a cylinder head of a high-pressure common rail diesel engine, the cylinder has a tangential air inlet I10 and a tangential air inlet II11 arranged up and down; the length of the tangential air inlet I10 is longer than the tangential air inlet Length of track II 11; combined Figure 7 , Figure 8 , the tangential air inlet I10 and the tangential air inlet II11 are both curved cavity structures, that is, the tangential air inlet I10 and the tangential air inlet II11 all include sequentially connected cylinder head The horizontal section I extending inward from the intake end, the curved arc section extending toward the inside of the cylinder head, and the horizontal section II extending curvedly toward the bottom surface of the cylinder head; The included angle between them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com