Compressor oil-running-preventing mechanism

A compressor and casing technology, applied in the field of compressors, can solve problems such as easy leakage of lubricating oil, and achieve the effects of avoiding direct contact, reducing wear, and avoiding oil shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

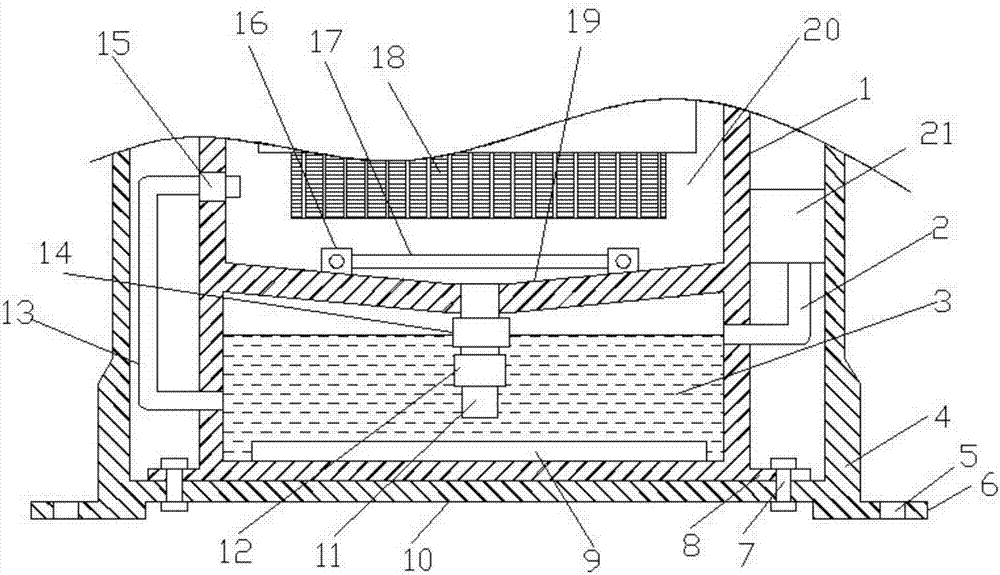

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0018] refer to figure 1 , a compressor anti-running oil mechanism, comprising a casing 1, a casing 4 is set on the outside of the casing 1, a plurality of mounting plates 6 are provided at the bottom of the casing 4, mounting holes 5 are provided on the mounting plates 6, and the bottom of the casing 4 is provided with There is a U-shaped groove 10, and the shell 4 is a stainless steel shell. The bottom of the casing 1 is provided with a plurality of connecting plates 8 , and connecting bolts 7 are connected between the connecting plates 8 and the shell 4 . The shell 1 plays the role of protecting and strengthening the structure, the installation hole 5 is used to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap