Super fastening sleeve piece

A fastening and kit technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problems of increased processing cost and raw material cost, incomplete fastening effect, and inability to reuse. Achieve the effect of reducing workload and danger possibility, reasonable structure design and saving material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

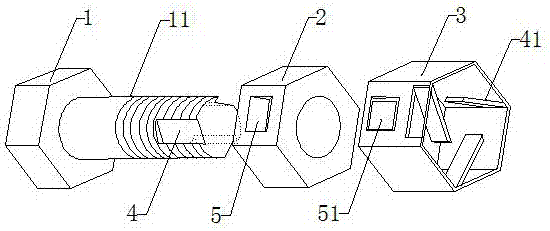

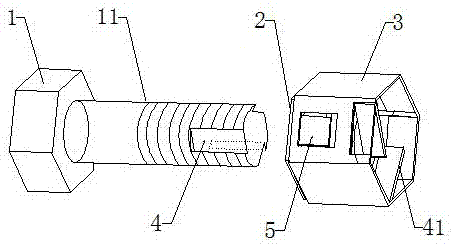

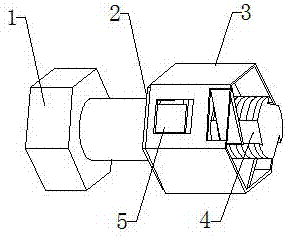

[0041] Embodiment 1: as Figure 1-3 As shown in 12, a super fastening kit includes bolts, nuts, and shaft locks, the bolts include screw rods, the nuts are hexagonal nuts, and the shaft locks are hexahedral and can be socketed on the nut Together, it also includes a circular motion limiting mechanism that prevents the screw and the nut from rotating with each other, that is, a strip-shaped limiting groove located outside the screw rod and a strip-shaped limiting groove located at the distal end of the shaft lock and the strip-shaped limiting mechanism. The circlip shrapnel that fits the bit groove, the axial movement limiting mechanism that prevents the shaft lock and the nut from falling off each other, that is, the nut card slot on the side wall of the nut and the shaft lock The nut retaining spring at the proximal end and adapted to the nut retaining groove has three strip-shaped limiting grooves and retaining spring springs, which are distributed in a three-legged shape, a...

Embodiment 2

[0045] Embodiment 2: as Figure 4-6 , 12, the difference between this embodiment and embodiment 1 is that the circular movement limiting mechanism is an irregular limiting slot arranged at the tail end of the screw and an irregular limiting slot arranged at the distal end of the shaft lock and the The irregular limit slots are adapted to the circlip springs, and the irregular limit slots and the matched circlips are in the shape of one-way propellers, and the cross-section of the irregular limit slots is irregular , the depth of the limiting slot in the axial direction of the screw rod can just accommodate the height of the clip spring piece, and can also be greater than the height of the clip spring piece.

Embodiment 3

[0046] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the circumferential movement limiting mechanism and the axial movement limiting mechanism are helical limiting grooves and The circlip shrapnel provided at the distal end of the shaft lock and matched with the helical limiting groove, there are three helical limiting grooves, and one circlip shrapnel, the two form a single ratchet mechanism for movement.

[0047] Installation method: 1. Screw the nut into the screw rod to the predetermined position where the circlip shrapnel can be inserted into the helical limit groove; 2. Put the shaft lock on the nut and tighten it ; 3. Pull out the shaft lock until the spring springs fall into the helical limit groove, or turn the shaft clockwise or counterclockwise until the spring springs fall into the spiral The limit groove is used to simultaneously limit the circumferential movement and the axial movement.

[0048] Disassembly method: 1. Insert the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com