Integrated fastener and use method thereof

A technology for fasteners and locking structures, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., which can solve the problem of imperfect fastening effects, high requirements for installation and use, and inability to be reused, etc. problems, to achieve the effect of reducing workload and danger, improving fastening effect, and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

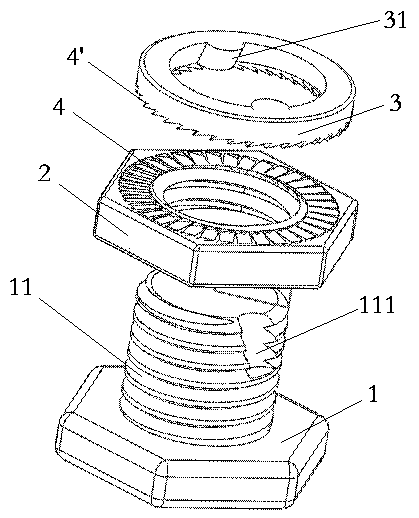

[0038] Embodiment 1: as figure 1 , 9 As shown, an integrated fastener includes a bolt, a nut, and a shaft lock. The shaft lock is in the shape of a ring. The circular movement limiting mechanism and the axial movement limiting mechanism to prevent the shaft lock and the nut from falling off each other, the shaft lock is simultaneously connected with the nut through the circumferential movement limiting mechanism and the axial movement limiting mechanism It is integrated with the screw rod, and the circular motion limiting mechanism is a spiral strip-shaped limiting groove arranged on the outside of the screw rod and a spiral-shaped strip-shaped limiting groove arranged on the shaft center lock and the spiral strip-shaped limiting groove. The grooves engage with each other and the protrusions are arranged on the inner side of the shaft lock ring, the protrusions are in the shape of a semicircle, and the helical direction of the spiral strip-shaped limiting groove is opposite ...

Embodiment 2

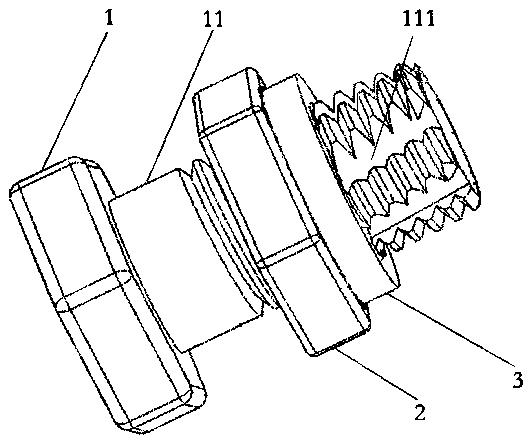

[0041] Embodiment 2: as Figure 2-3 As shown in , 9, the difference between this embodiment and embodiment 1 is that the number of the spiral strip-shaped limiting grooves and the protrusions are both six, and the shape of the protrusions is triangular.

Embodiment 3

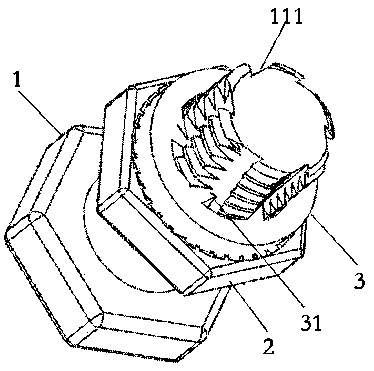

[0042] Embodiment 3: as Figure 4 , 9 As shown, the difference between this embodiment and Embodiment 1 is that the concave-convex structure is tooth-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com