Leak detection device for water boiling heating container and leak detection method thereof

A technology for heating containers and leak detection, which is used in the testing of machine/structural components, instruments, and fluid tightness testing, etc., can solve problems such as affecting the appearance, separation of the cup body from the aluminum plate and aluminum tube, and different elastic modulus. To achieve the effect of simple structure and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

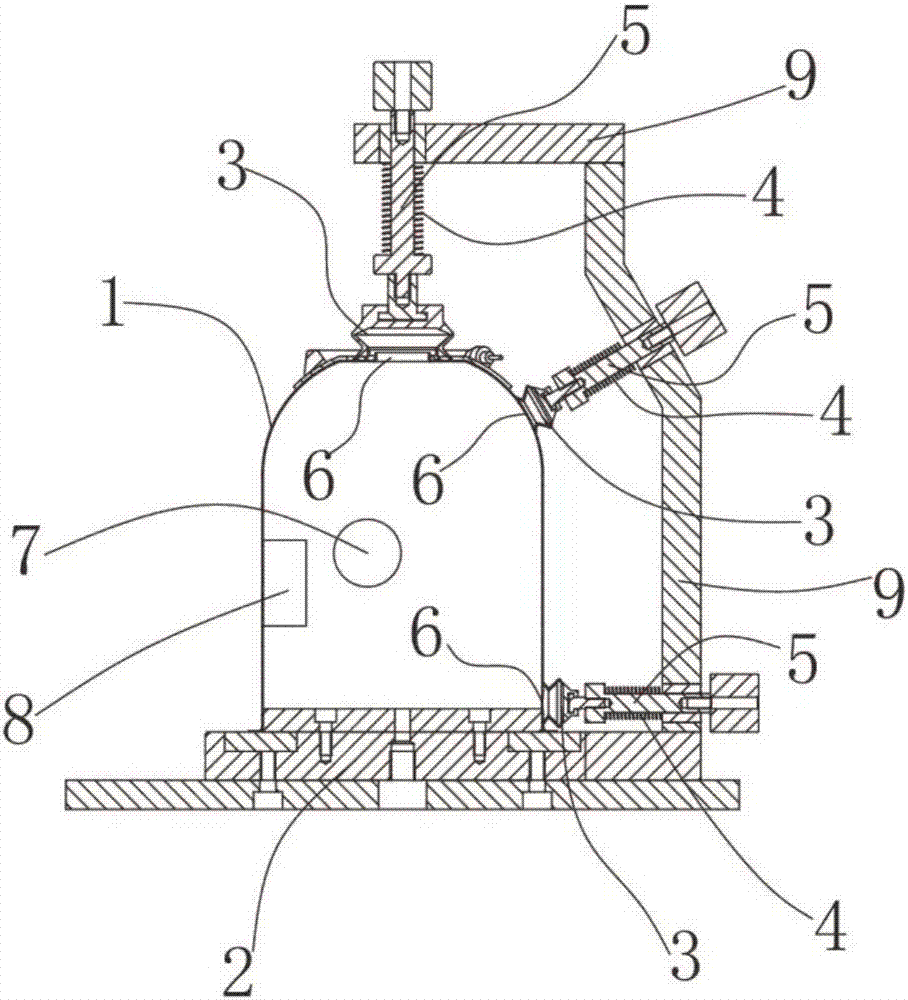

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. like figure 1 As shown, a leak detection device for a boiling water heating container includes a positioning tool 2 for placing a boiling water heating container 1, a vacuum gauge 7 and a vacuum pumping device for evacuating the boiling water heating container 1 8. Each sealing hole 6 of the boiling water heating container 1 is provided with a suction cup 3, a compression spring 4 and a blocking plate 9 in sequence. One end of the compression spring 4 is against the suction cup 3, and the other end of the compression spring 4 is against the suction cup. Blocking plate9. The elastic force of the compression spring 4 fits the suction cup 3 to the sealing hole 6 , so that the suction cup 3 can seal the sealing hole 6 without other external force during the vacuuming process.

[0011] The compression spring 4 is sleeved on a positioning rod 5 to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com