[0005] The beneficial effect of such setting is: adopt the above scheme, fix the pressure switch to be tested in the sealed cavity, turn on the power switch, the first

electromagnetic valve starts to work, open the first switch at the same time, keep the second switch closed, the first

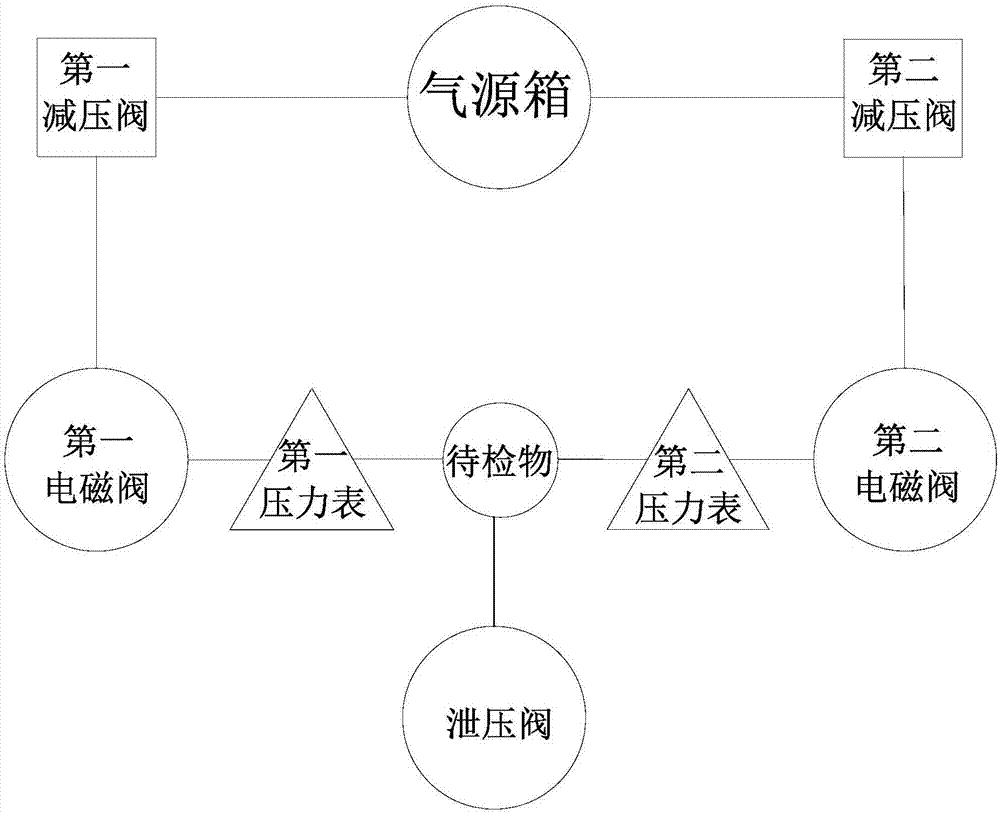

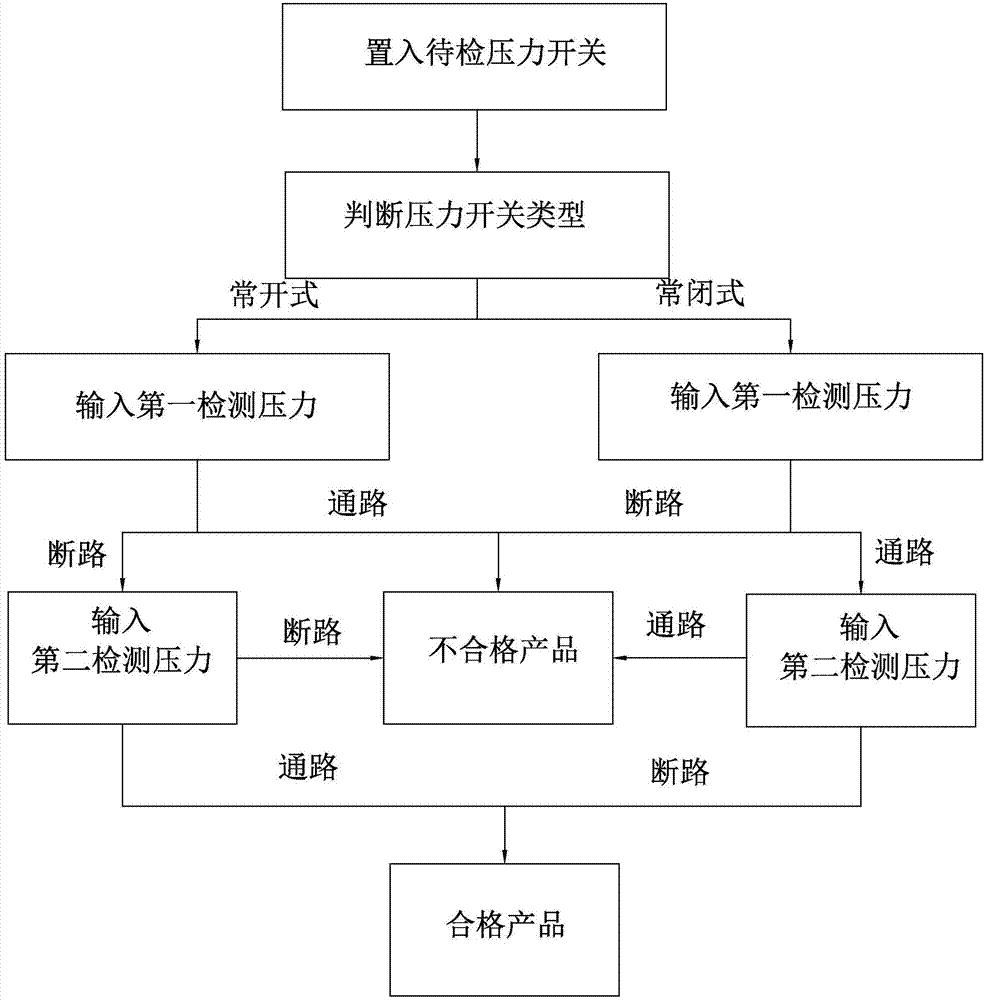

electromagnetic valve The valve applies pressure to the pressure switch to be tested in the sealed cavity through the first conduit. The air pressure set by the first solenoid valve is smaller than the rated pressure of the pressure switch. If the pressure switch is normally open, under the air pressure of the first solenoid valve If it is turned on, the rated pressure setting of the pressure switch is wrong, and it is an unqualified product. If the pressure switch is normally closed, and it is in the open circuit state under the air pressure of the first solenoid valve, the rated pressure setting of the pressure switch is wrong. , is an unqualified product, if the product is qualified under the air pressure of the first solenoid valve, then close the first solenoid valve, open the pressure

relief valve at the same time to release the pressure, then open the second solenoid valve, the first switch is closed, the second switch is open, The set pressure of the second solenoid valve is higher than the rated pressure of the pressure switch. If the pressure switch is normally open and is in the conduction state under the air pressure of the second solenoid valve, the rated pressure of the pressure switch is set incorrectly. Qualified products, if the pressure switch is normally closed, and it is in the open circuit state under the air pressure of the second solenoid valve, then the rated pressure setting of the pressure switch is wrong, and it is an unqualified product. If the two tests pass, the pressure switch is For qualified products, after opening the pressure

relief valve to release the pressure, open the sealed cavity. After the pressure is released, the sealed cavity is easier to open and

safer. That is, a certain range is set through the first solenoid valve and the second solenoid valve. As long as the pressure switch If the rated pressure of the pressure switch falls within this range, the pressure switch can be considered as a qualified product. According to different product requirements, the

pressure difference between the first solenoid valve and the second solenoid valve can be very large or small, so as to realize the control of different products. The required detection, this detection method can set the program for control detection, that is, the first solenoid valve is controlled by the single-

chip microcomputer to open, and the second solenoid valve is closed. When the single-

chip microcomputer is used for control, the first switch and the second switch can be kept open. , the control

chip controls the airtightness of the valve passages on both sides, and then judges in the above way. If the first step is unqualified, it will be reminded by lighting up or sounding to remind the defective products to be removed. If the first step is qualified, it will be closed. The first solenoid valve, after completing the pressure relief operation, open the second solenoid valve, judge and set it according to the above method, if it is also unqualified, it will be reminded by lighting up or sounding to remind the defective products to be removed, and if it is qualified, the solenoid valve will be interrupted Work, after the pressure relief operation is completed, open the sealed cavity to take out the product and put it into the next pressure switch to be tested. This detection method is convenient and fast, and the detection is more accurate at the same time. Of course, this detection method can also be used manually. The method of opening and closing the solenoid valve and the switch in turn can be manually switched on and off the first switch and the second switch when there is a problem with the single-chip

microcomputer or the control chip, so as to ensure the sealing of the working pipeline and the accuracy of manual operation. The first switch and the second switch can detect the airtightness of the solenoid valve pipeline during equipment testing, further improving the stability and reliability of the equipment, making the equipment more adaptable to use, and at the same time, the equipment is easy to operate and convenient for workers to carry out. Learning to use, while avoiding the reading of workers during detection, further improving the detection accuracy of the equipment

Login to View More

Login to View More  Login to View More

Login to View More