Composite salt spray test chamber

A compound salt and test box technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as functional limitations, environmental pollution, and low intelligence, and achieve simple and compact box structure, convenient installation and use, and intelligence high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings.

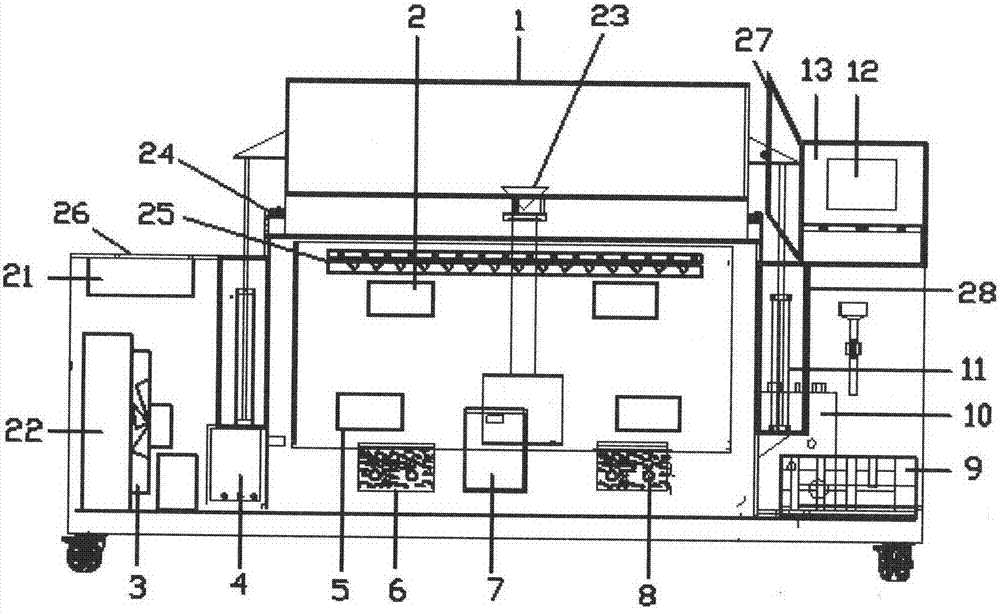

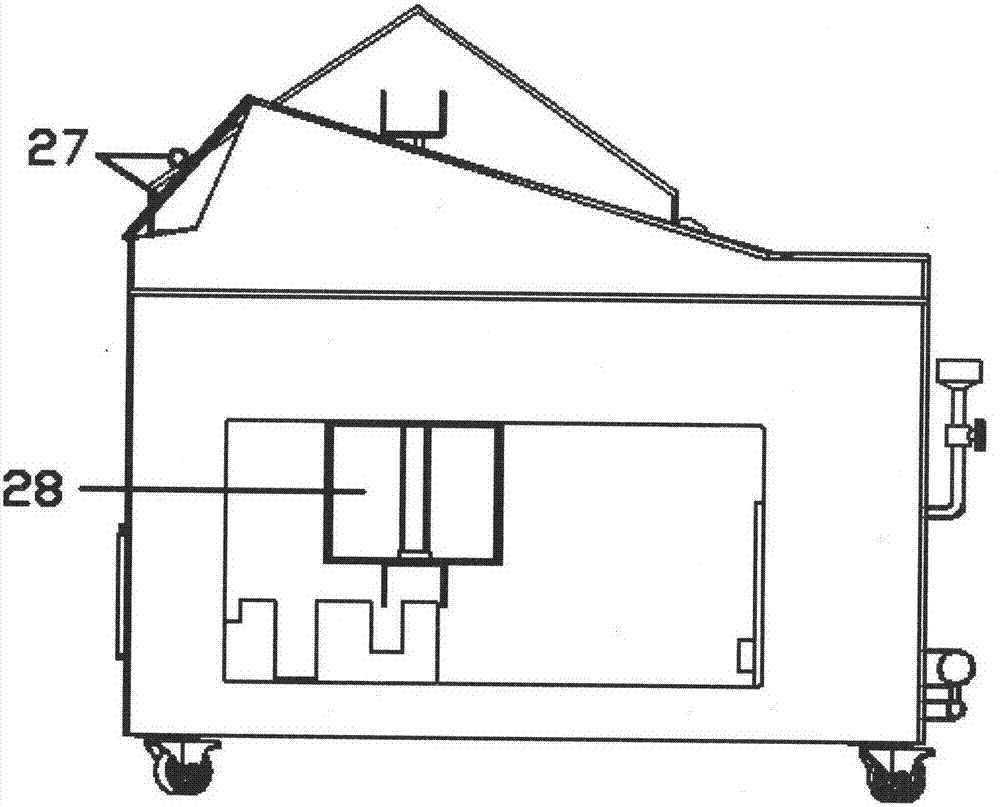

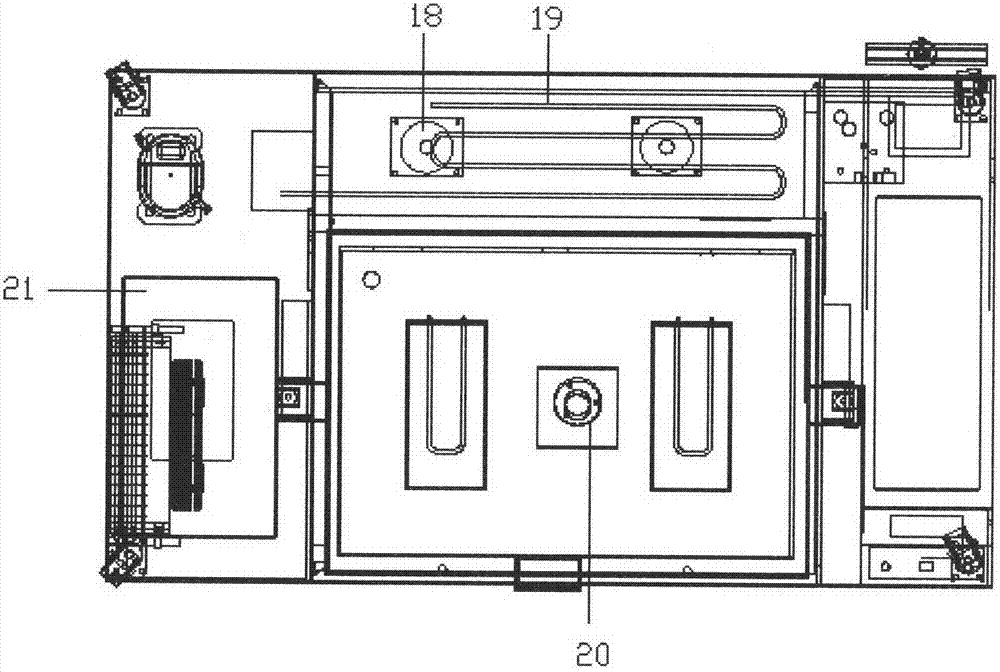

[0019] see Figure 1-3 , the composite salt spray test box includes a box body 26, a control panel 13, a salt spray system, a humidity system, and a refrigeration system. The salt spray system is composed of a salt water tank 21, a saturated bucket 10, a nozzle, etc. On the left side of the body 26, the compressed air communicates with the saturation bucket 10 located on the right side inside the box body 26. The saturation bucket water inlet 14 is arranged above the saturation bucket 10, and the spray 20 delivered to the middle of the box body 26 is connected through a pipeline, and then passed through the spray tower 20. The nozzle on the top sprays salt mist. The humidity system consists of a humidifying boiler 4, a humidifying water tank 6 and a U-shaped heating tube 8. The humidifying boiler 4 is on the left side of the box body 26, and the humidi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com