Method of manufacturing high voltage sampling device

A technology of voltage sampling and manufacturing method, which is applied to measuring devices, measuring electrical variables, manufacturing measuring instruments, etc., can solve the problems of low sensitivity, high sensitivity, small size, etc. volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

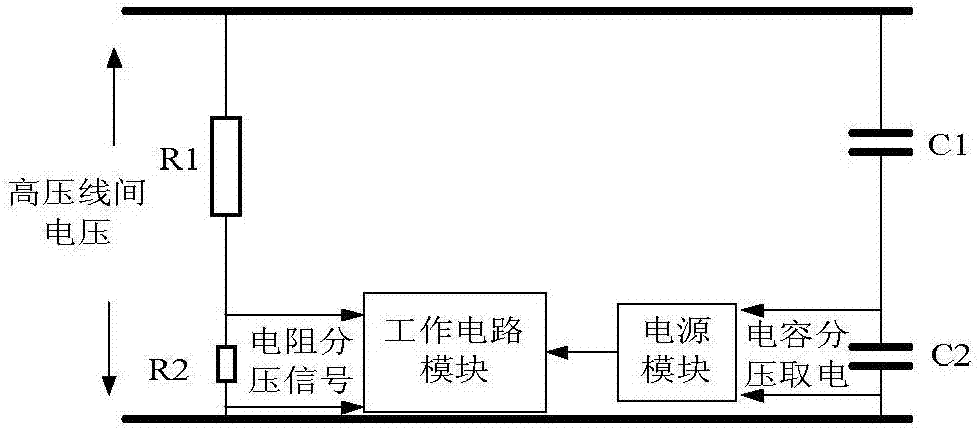

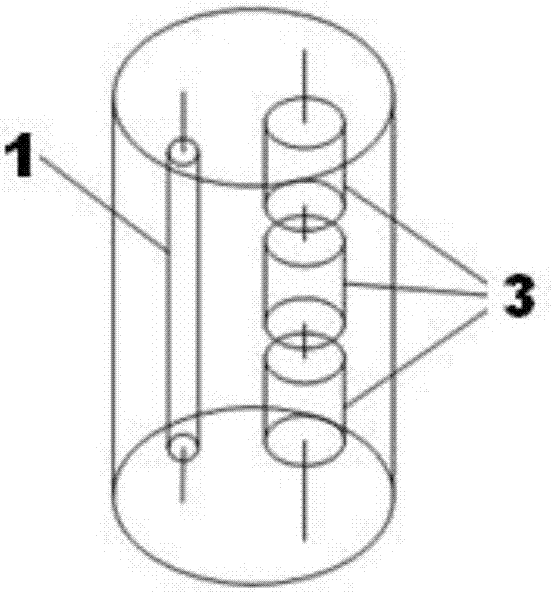

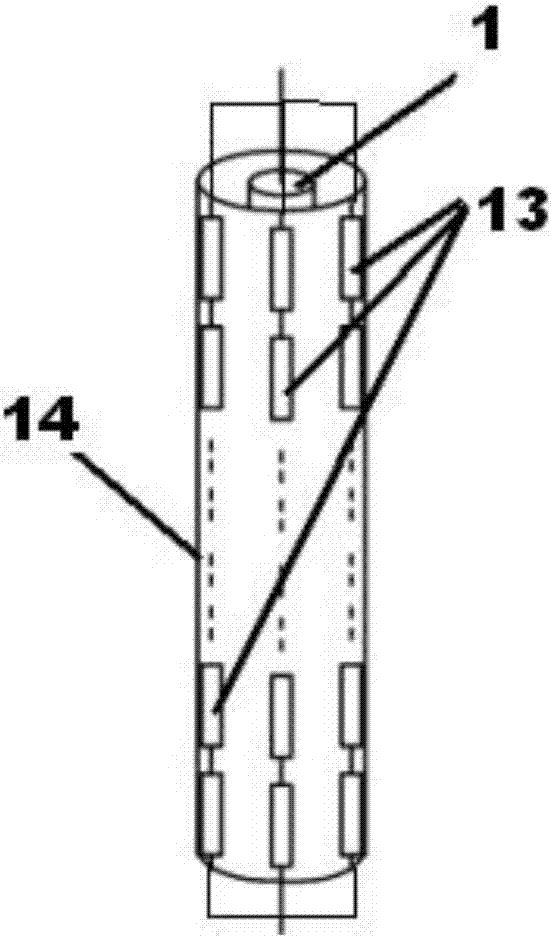

[0037] Such as Image 6 The illustrated embodiment is a manufacturing method of a high-voltage voltage sampling device, which includes a potting cavity 5 with openings at both ends, and two working circuit cavities 6 respectively arranged at both ends of the potting cavity, extending into the potting cavity Insulating fiberglass bushing 2 in the space surrounded by two working circuit cavities, high-voltage voltage dividing resistor 1 set in the insulating glass fiber bushing, high-voltage metallized film capacitor set on the insulating glass fiber bushing 3. Two metal shielding electrodes 4 arranged at both ends of the insulating glass fiber bushing and respectively connected to both ends of the high-voltage voltage dividing resistor, and an insulating cylinder 9 arranged on the outer peripheral surface of the potting cavity and connected to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com